Получите быструю расценку

Сварная нержавеющая труба

Изготавливается из стальной полосы методом формовки и длинной сварки без использования присадок.

Сварная вытянутая труба

После сварки труба дополнительно вытягивается до нужного размера. Такой способ позволяет получить толстостенные трубы с лучшими размерами, оставаясь более экономичными, чем синтетический вариант. Все женщины проносят незабываемый отжиг.

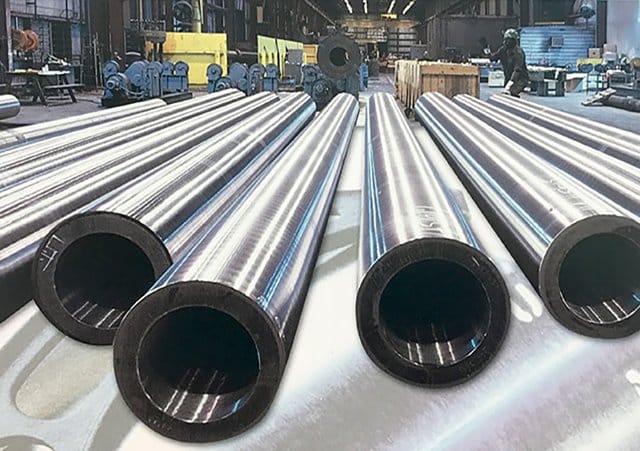

Бесшовная нержавеющая труба

Производится прокаткой или горячей экструзией из цельного слитка. окружающей среде и при высоких температурах.

DA Xun находится в районе W Usu, Цзянсу, Китай.

| Параметры продукта: труба нержавеющая. | |||

| ОД | 3мм~2000мм | толщина | 0,3мм~100мм |

| Стандарт | ГОСТ 9941-81, ГОСТ 5632-72, ГОСТ 10704-91, ГОСТ 17375-2001 / ГОСТ 9940-81, ГОСТ 17375-2001, ГОСТ 30732-2006, ГОСТ 2590-2006 / ГОСТ 10498-82 ASTM A312 А249 А213 А269 А268 и т. д. | ||

| ДАННЫЕ | БесшовныйСварная трубаТочность трубПолировка трубТравление трубТруба с волосяным покровомТруба и т. д. | ||

| форма | Круглый, квадратный, прямоугольный, шестиугольный, специальной формы и т. д. | ||

| Оценка | 304 304DQ 201 301 304L 304H 309S 310S 316L 316TI 317L 321 347 347H 430 410 410S 420 420J2 430 430LNT 430J1L 434 436L 439 441 443

444 904L 2205 2507 S32750 S32760 445J2 442 и т.д. |

||

Daxun — китайский производитель труб из нержавеющей стали, который изготавливает прецизионные бесшовные цилиндрические формы и компоненты, включая трубы стандартных спецификаций и с жесткими допусками, тонкостенные трубы и трубы из нержавеющей стали из различных материалов, включая трубы стандартных спецификаций и трубы из титановых сплавов, трубы из нержавеющей стали, высокопрочные стальные трубы и трубы из сплавов на основе никеля.

Благодаря глобальному обслуживанию и поддержке цепей бесшовных и сварных труб из нержавеющей стали компания Daxun установила стандарт для труб большого диаметра из нержавеющей стали в энергетической, нефтехимической, атомной, аэрокосмической и оборонной промышленности.

Марки и характеристики различных труб из нержавеющей стали

Сила обеспечивает неизменно высокое качество труб из нержавеющей стали.

Труба из дуплексной нержавеющей стали, с повышенной прочностью и коррозионной стойкостью

Мы производим бесшовные высокопрочные трубы диаметром от 1″ до 50″.

Трубы из нержавеющей стали, изготовленные из этого материала, обладают хорошей устойчивостью к высоким температурам.

317L — труба из нержавеющей стали, произведенная в соответствии с американскими стандартами ASTM.

Труба из дуплексной нержавеющей стали, с повышенной прочностью и коррозионной стойкостью

Труба из дуплексной нержавеющей стали, с повышенной прочностью и коррозионной стойкостью

Нержавеющая труба 904L Обладает хорошей коррозионной стойкостью и производительностью.

Квадратные трубы из нержавеющей стали часто используются в строительстве и в качестве конструкционных деталей.

Обычно используемые сорта

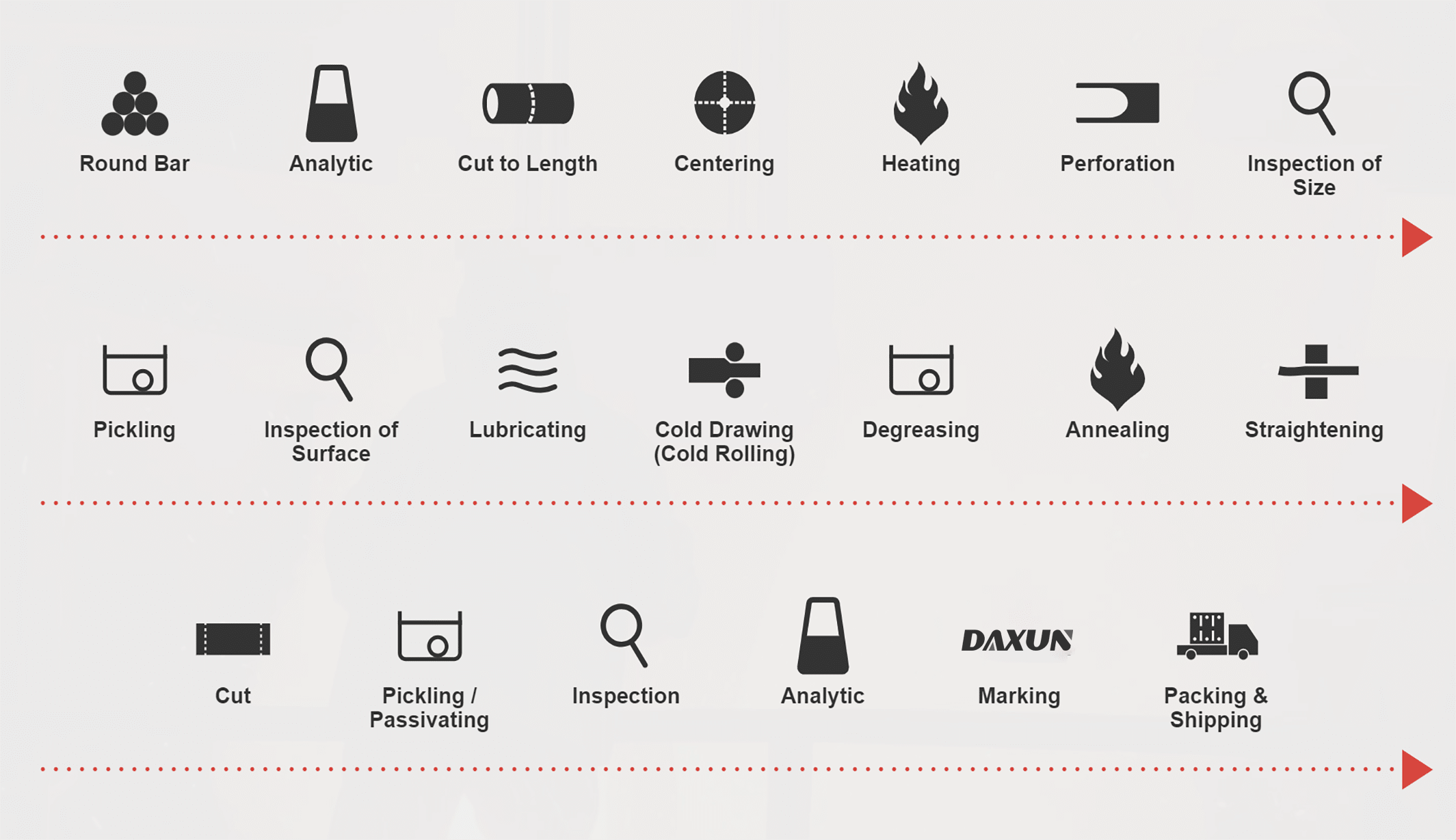

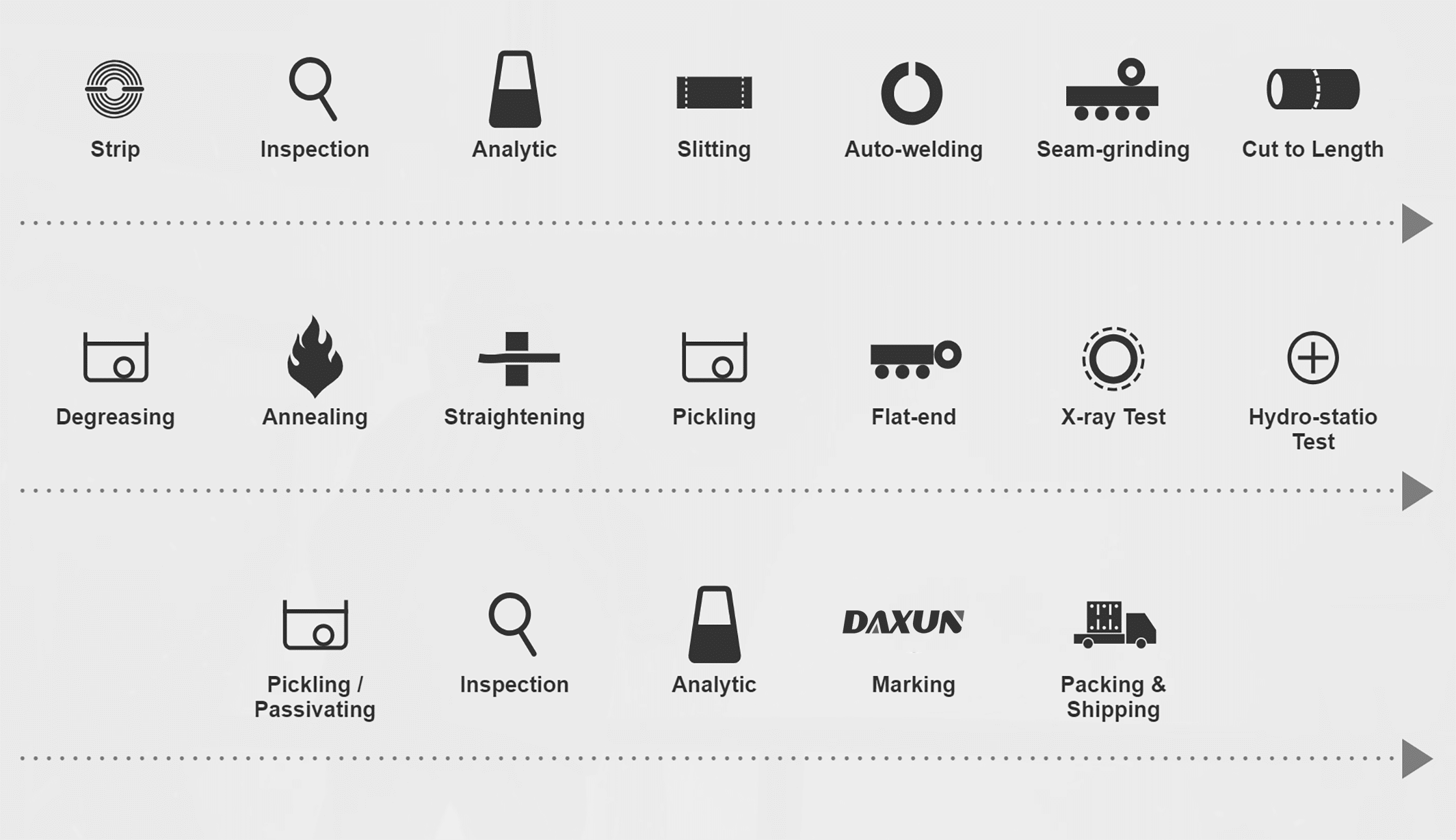

Методы производства

Каждая труба производится в соответствии со строжайшими нормативными и внутренними спецификациями. Запатентованные процессы формовки, сварки и отделки Daxun производят трубы и трубы с превосходными характеристиками. Некоторые этапы производства перечислены ниже в случайном порядке.

Основные характеристики труба нержавеющая

Отличная коррозионная стойкость в экстремальных условиях

Многие типы труб из нержавеющей стали обладают очень высокой прочностью. Многие типы труб из нержавеющей стали обладают очень высокой прочностью.

Подходит для ситуаций, когда необходимо избегать помех от магнитного поля.

Способность выдерживать очень высокие температуры делает никелевые сплавы идеальными для применения на суше, на море и в энергетике.

Возможности производства труб из нержавеющей стали Daxun

Возможности формовки включают в себя современные активы экструзии и холодной обработки для производства трубной продукции, один из крупнейших в мире колонных станов и уникальные процессы гидроформовки для производства фитингов.

Возможности обработки труб Daxun

Как вертикально интегрированный производитель, мы предлагаем комплексное обслуживание и имеем возможность справиться с любыми задачами, будь то целый проект или просто работа по механической обработке. Правка, сверление, хонингование, трепанация, резка, испытания, расточка, механическая обработка, лазерная сварка, полировка, токарная обработка, специализированные услуги.

Более крупные и лучшие решения для труб

С вертикальными и горизонтальными прессами от 12 000 тонн до 35 000 тонн Daxun обладает самыми полными возможностями экструзии труб в мире. Возможности позволяют нам производить трубы самой большой длины и диаметра в отрасли.

Мощные решения для труб

Компания Daxun поставляет на рынок электрогенерации воздуховоды, котельные трубы, главные паровые трубы, трубы промежуточного нагрева, установки десульфурации дымовых газов и другую продукцию для атомной, угольной, возобновляемой энергетики и комбинированного цикла.

Техническая информация

Мы поставляем трубы и трубопроводы для оборонной промышленности, а также для различных механических и конструкционных применений, где используются трубные изделия. Высоколегированные никелевые обсадные трубы и механические трубные изделия используются в самых технически сложных отраслях и приложениях в мире, включая кислые среды, высокие давления и температуры.

Продукция химической обработки включает трубы и трубки для производства этилена, производства каустической соды и теплообменные трубки. Мы также производим разнообразную продукцию для медицинской и общепромышленной промышленности, включая рентгеновские аппараты, термопарные оболочки для промышленных печей и котельные трубки.

В Daxun у нас есть испытательная лаборатория и оборудование, чтобы гарантировать, что наши материалы из нержавеющей стали имеют фактический вес и хорошее качество перед отправкой. Наша строгая команда контроля качества также проводит строгую и 100% проверку на всех этапах производства.

Наша поддержка и услуги не ограничиваются только началом наших транзакций. Даже если вы получили свои заказы, TuoLian продолжит предоставлять превосходное послепродажное обслуживание. Мы продолжим предоставлять помощь и гарантию на ваши заказы.

Примеры применения труб из нержавеющей стали в различных отраслях промышленности

Компания Daxun Stainless разработала технологию НИОКР и производства для труб из сплава N08825 для применения водорода под высоким давлением. Продукция и различные механические, физические и химические свойства достигли международного передового уровня, отвечая требованиям к использованию бесшовных труб из сплава для применения водорода под высоким давлением и реализуя применение водорода под высоким давлением. трубы для атомной энергетики, нефтехимии, переработки угля в жидкость, химической промышленности, аэрокосмической промышленности и другого основного оборудования и производства высокотехнологичного оборудования.

В тепловой энергетике возросло использование сверхкритических и ультрасверхкритических установок. Сверхкритическая установка повышает тепловую эффективность установки за счет повышения давления и температуры пара в котле. Ее паровые и водяные трубопроводы включают трубы подогревателя, трубы пароперегревателя, трубы водяного экрана, трубы экономайзера, трубы предварительного подогрева воздуха, трубы теплопередачи и опускные трубы. Различные коллекторные трубы подвергаются воздействию высоких температур и высокого давления в течение длительного времени, поэтому стальные трубы должны обладать высокой прочностью, высокой стойкостью к окислению и коррозии и хорошей структурной стабильностью. Обычно количество труб котла высокого давления, таких как Super304H и HR3C, потребляемых на миллион киловатт сверх(сверх)критических установок, составляет около 1250 тонн.

Компания Daxun разработала технологию производства бесшовных труб большого диаметра из супердуплексной нержавеющей стали, осуществила трансформацию научных и технологических достижений в высокотехнологичную продукцию для судостроения и послужила примером индустриализации ключевого оборудования и систем в производстве высокотехнологичных судов и морской техники.

Daxun вошла в число квалифицированных поставщиков и разработала основную технологию производства бесшовных и сварных стальных труб N08367 для ядерной энергетики третьего поколения AP1000, достигнув основных целей индустриализации. Достигнув международного передового и ведущего уровня, реализация проекта будет эффективно способствовать независимости ядерной энергетики, удовлетворять потребности в развитии отечественного и зарубежного производства передового ядерно-энергетического оборудования и обеспечивать безопасную эксплуатацию атомных электростанций.

Сосредоточившись на эксплуатационных требованиях к сварным трубам для СПГ, компания Daxun осуществила прорыв в ключевых технологиях сварки и термообработки в процессе обработки и производства продукции и разработала сварные трубы большого диаметра из нержавеющей стали для СПГ с превосходной коррозионной стойкостью, низкотемпературной вязкостью и хорошей прочностью при низких температурах.

Может использоваться в деталях фюзеляжа, аэрокосмическом оборудовании, ракетах, искусственных спутниках, снарядах, корпусах космических аппаратов, трубопроводных системах и т. д.

Обслуживая нефтехимическую промышленность, она может использоваться в: реакционных башнях, теплообменниках, напорных шахтах, дистилляционных башнях, клапанах, насосах, различных трубопроводных системах и т. д. Выбирая Daxun в качестве поставщика труб из нержавеющей стали, вы можете быть уверены, что мы действительно понимаем нефтегазовую промышленность. Свяжитесь с Daxun сегодня.

Выбрав Daxun в качестве поставщика труб из нержавеющей стали, вы можете быть уверены, что мы действительно разбираемся в бронетанковой и автомобильной промышленности. Свяжитесь с Daxun сегодня.

Трубы из нержавеющей стали используются при изготовлении судовых трубопроводных систем, штыревых антенн, трубопроводов морской воды, конденсаторов, теплообменников, акустических устройств, пожарных трубопроводов и т. д.

Оборудование для глубоководной разведки является одним из важных направлений в области морской техники, а трубы из нержавеющей стали стали идеальным материалом для различного оборудования для глубоководной разведки благодаря своей коррозионной стойкости, высокой прочности и другим преимуществам. Глубоководные трубопроводы, детекторы, гидролокационное оборудование и т. д. могут быть изготовлены из труб из нержавеющей стали, что гарантирует их долгосрочную надежную эксплуатацию в суровых морских условиях.

Обслуживание фармацевтической и биофармацевтической промышленности стало желанным вызовом для Daxun. От выбора сырья до доставки мы разработали услуги высокой и сверхвысокой чистоты, чтобы соответствовать и превосходить отраслевые стандарты. Когда только лучшие трубки из нержавеющей стали и трубы из нержавеющей стали могут удовлетворить спрос, все больше фармацевтических и биофармацевтических компаний доверяют Daxun.

Работая в сфере производства электроэнергии, Daxun может объединить технические знания и опыт для производства лучших труб и труб, доступных сегодня. Когда вы выбираете лучшее, вы получаете лучшее. Следуйте примеру бесчисленных других компаний — доверяйте Daxun. Высокотребовательным отраслям нужен Daxun

Техническая информация

- Частичная инвентаризация

- Допуски ASTM A269

- Допуски ASTM A554

- Допуски ASTM A312

- Состояние доставки

- Процесс производства бесшовных труб

- Процесс производства сварных труб

| Диаметр (мм) | Толщина (мм) | Длина (мм) | Комментарий |

| φ3.0-12.0 | 0,3-1,0 | 6000 | ААА |

| φ19,0-22,0 | 0,6-3,0 | 6000 | ААА |

| φ25,0-27,2 | 0,8-10,0 | 6000 | ААА |

| φ32,0-60,3 | 0,8-15,0 | 36000 | ААА |

| φ76.3-102.1 | 0,8-205,0 | 36000 | ААА |

| φ114,3-168,3 | 0,8-20,0 | 6000 | ААА |

| φ180,0-219,2 | 3,0-20,0 | 6000 | ААА |

| φ273.1-325.3 | 4.0-30.0 | 6000 | ААА |

| φ377.2-426.3 | 5.0-30.0 | 6000 | ААА |

| φ508.1-711.0 | 5.0-30.0 | 6000 | ААА |

| 711.0+

|

5.0-30.0

|

6000

|

ААА

Если вам нужна дополнительная информация о размере, свяжитесь с Daxun. |

| ASTM A269 | ||||||

| Группа | Размер, наружный диаметр, дюймы. | Допустимые отклонения наружного диаметра, дюймы (мм) | Допустимые отклонения толщины стенки, % | Допустимые отклонения в длине реза, дюймы (мм) | Тонкостенные трубы | |

| Над | Под | |||||

| 1 | До ½ | ±0,005(0,13) | ±15 | ⅛(3.2) | 0 | … |

| 2 | ½ до 1½, за исключением | ±0,005(0,13) | ±10 | ⅛(3.2) | 0 | менее 0,065 дюйма (1,65 мм) номинал |

| 3 | 1½ до 3½, за исключением | ±0,010(0,25) | ±10 | 3/16(4.8) | 0 | менее 0,095 дюйма (2,41 мм) номинал |

| 4 | 3½ до 5½, за исключением | ±0,015(0,38) | ±10 | 3/16(4.8) | 0 | менее 0,150 дюйма (3,81 мм) номинал |

| 5 | 5½ до 8, за исключением | ±0,030(0,76) | ±10 | 3/16(4.8) | 0 | менее 0,150 дюйма (3,81 мм) номинал |

| 6 | 8–12, за исключением | ±0,040(1,01) | ±10 | 3/16(4.8) | 0 | менее 0,200 дюйма (5,08 мм) номинал |

| 7 | 12–14, за исключением | ±0,050(1,26) | ±10 | 3/16(4.8) | 0 | менее 0,220 дюйма (5,59 мм) номинал |

| ASTM A554 | ||||

| Размер наружного диаметра, дюйм (мм) | Толщина стенки | ОП, ± | ||

| в. | мм | в. | мм | |

| Меньше ½ (12,7) | 0,020 – 0,049 | 0,51 – 1,24 | 0,004 | 0.1 |

| ½ к 1 (12,7 к 25,4) | 0,020 – 0,065 | 0,51–1,65 | 0,005 | 0,13 |

| ½ к 1 (12,7 к 25,4) | более 0,065 до 0,134 | более 1,65 до 3,40 | 0.01 | 0,25 |

| Более 1 до 1½ (25,4 до 38,1), вкл. | 0,025 – 0,065 | 0,64 – 1,65 | 0,008 | 0.2 |

| Более 1 до 1½ (25,4 до 38,1), вкл. | более 0,065 до 0,134 | более 1,65 до 3,40 | 0.01 | 0,25 |

| Более 1½ до 2 (38,1 до 50,8), вкл. | 0,025 – 0,049 | 0,64 – 1,24 | 0.01 | 0,25 |

| Более 1½ до 2 (38,1 до 50,8), вкл. | более 0,049 до 0,083 | более 1,24 до 2,11 | 0,011 | 0,28 |

| Более 1½ до 2 (38,1 до 50,8), вкл. | более 0,083 до 0,149 | более 2,11 до 3,78 | 0,012 | 0.3 |

| От 2 до 2½ (от 50,8 до 63,5), вкл. | 0,032 – 0,065 | 0,81 – 1,65 | 0,012 | 0.3 |

| От 2 до 2½ (от 50,8 до 63,5), вкл. | более 0,065 до 0,109 | более 1,65 до 2,77 | 0,013 | 0,33 |

| От 2 до 2½ (от 50,8 до 63,5), вкл. | более 0,109 до 0,165 | более 2,77 до 4,19 | 0,014 | 0,36 |

| Более 2½ до 3½ (63,5 до 88,9), вкл. | 0,032 – 0,165 | 0,81 – 4,19 | 0,014 | 0,36 |

| Более 2½ до 3½ (63,5 до 88,9), вкл. | более 0,165 | более 4.19 | 0,02 | 0,51 |

| Свыше 3½ до 5 (88,9 до 127,0), вкл. | 0,035 – 0,165 | 0,89 – 4,19 | 0,02 | 0,51 |

| Свыше 3½ до 5 (88,9 до 127,0), вкл. | более 0,165 | более 4.19 | 0,025 | 0,64 |

| От 5 до 7½ (от 127,0 до 190,5), включительно | 0,049 – 0,250 | 1,24 – 6,35 | 0,025 | 0,64 |

| От 5 до 7½ (от 127,0 до 190,5), включительно | более 0,250 | более 6.35 | 0,03 | 0,76 |

| От 7,5 до 16 лет (от 190,5 до 406,4), вкл. | все | все | 0,00125 дюйм/дюйм или мм/мм окружности | |

| ASTM A312 | ||

| Обозначение NPS | Допуск, % от номинала | |

| Над | Под | |

| От ⅛ до 2½ включительно, все соотношения t/D | 20 | 12.5 |

| 3 по 18 включительно, т/д до 5% включительно. | 22.5 | 12.5 |

| 3-18 включительно, t/D > 5% | 15 | 12.5 |

| 20 и более, сварные, все соотношения t/D | 17.5 | 12.5 |

| 20 и более, бесшовные, т/д до 5% вкл. | 22.5 | 12.5 |

| 20 и более, бесшовные, t/D > 5% | 15 | 12.5 |

| Состояние доставки | |

| Выбор штата доставки | Состояние поверхности |

| Горячекатаный | Яркий серебристый |

| Полированный (320#, 400#, 600#, зеркальная отделка) | |

| Холоднокатаный | Яркий серебристый |

| Полированный (320#, 400#, 600#, зеркальная отделка) | |

| Примечание: | |

| 1. Если вам требуется другой штат доставки, чем указанный выше, пожалуйста, согласуйте это с нами. | |

| 2. В случае возникновения каких-либо вопросов или заказов, пожалуйста, сообщите нам о любых дополнительных требованиях, не указанных здесь. | |

Сопутствующие товары

Сплав Даксун

Что касается труб из нержавеющей стали, мы можем обработать любой тип запроса. Пожалуйста, не стесняйтесь спрашивать нас. Мы дадим рекомендации на основе потребностей каждого клиента.

Да, у нас есть полные спецификации и запасы, и мы можем быстро удовлетворить ваши потребности.

Да, его можно настроить. Вы можете связаться с нами и отправить нам индивидуальные характеристики и количество.

Наши методы транспортировки обычно включают морскую перевозку, наземную перевозку и морскую перевозку. Доберемся до вас быстро и безопасно.

Поскольку объемы производства у нас высокие, себестоимость будет значительно ниже, поэтому и цена низкая.

Мы придаем большое значение качеству продукции и прошли различные испытания системы качества.