Daxun is a stockist and manufacturer of stainless steel coils and strips

- Daxun has 30,000 tons of stainless steel coils in stock

- Cold-rolled stainless steel coils and hot-rolled stainless steel coils

- Surface processing services for stainless steel coils are available

- Large amounts of spot stock can be shipped quickly

Stainless Steel Coil Products

| Width | 3.5mm~1500mm |

| Thickness | 0.02mm~6mm |

| Standard | AISI, JIS, SUS, GB, ASTM A240 and AMS |

| Density | 7.93g/cm³ |

| Surface finishes | Brushed, Polished, Embossed, BA, 2B, 2BA, 8K, NO.4, HL, SB, NO.1, 2H |

| Grades | 201, 202, 301, 304, 304L, 316, 316L, 316Ti, 321, 317l, and 430, 2205, 904l, 2507, 309s, 410s, 303, 309S, 310S, 347, 904L, 410, 414, 416, 416, 420, 431, 440A, 440B, 440C, S31803, S32101, S32205, S32304, S32750, 429, 430, 433, 434, 435, 436, 439, etc |

Daxun offers a full range of stainless steel alloys in the form of stainless steel coils, known for their reliability, durability, and high performance. We provide a wide selection of grades, from austenitic to ferritic series, suitable for both industrial and construction applications. Our austenitic series includes grades like 201, 304, 304L, 321, 316, 316L, and more, available in various surface finishes such as 2B, BA, No.4, 8K, SB, and HL.

For customers looking for unique properties and applications, our ferrite series includes 430, ultra-pure ferrite 443 and 436L/439/444/441. Duplex steels include S31808/S32205/S32750/S32760. These products meet thickness requirements from 0.4mm to 3.0mm and are available in a variety of surface finish options, including 2B, BA, NO.4, 8K, SB, HL, and more.

Stainless steel coil grades and characteristics

Each stainless steel coil material has its own different usage scenarios.

Stainless steel coil surface

If the surface you need is not available here, please contact Daxun.

Stainless steel rolls can be made into brushed surfaces for the whole roll

Stainless steel rolls can be made into mirror-like surfaces throughout the roll

Stainless steel coils can be made into bright annealed surfaces in full rolls

The original color of Daxun’s stainless steel coils is cold-rolled 2B surface

Da xun NO.1 The pickling surface is generally hot-rolled stainless steel coils

We can perform surface color plating according to the color card you provide

We can perform surface color plating according to the color card you provide

We can perform surface color plating according to the color card you provide

Commonly used thicknesses of stainless steel coils

We offer stainless steel coils in a wide range of thicknesses, suitable for all types of applications. Our products can be processed to the width you need, using advanced slitting and flying shear equipment.

Performance of Stainless steel coil

The chemical composition protects against rust, making it ideal for appliances and demanding environments.

Easy to work with and highly durable, reducing maintenance costs.

Stainless steel coils are known for their durability, low maintenance, and versatility.

Easy to shape, perfect for both large industrial uses and smaller, detailed applications.

Huge Stock Choiceable Material

With choiceable material from the very start comes our high quality stainless steel coil products.Daxun have stainless steel inventories for common grades and common sizes to ensure fast response to our customers’ demand.Mill Origin: TISCO, ZPSS, BAOSTEEL, JISCO, ZSESS, ATI, SMC, HAYNES, VDM, ArcelorMittal, Outokumpu, etc.

Stainless Steel Grades (300 and 2000 series)

Stainless steel grades are classified based on their composition, properties, and applications, making it easier to select the right material for specific needs. The most common stainless steel grades include:

- Austenitic Stainless Steels (e.g., 304, 316, 321): Known for their excellent corrosion resistance, high ductility, and good formability, these grades are widely used in various industries. Austenitic stainless steels are non-magnetic and can be easily welded and formed, making them ideal for applications requiring high corrosion resistance and aesthetic appeal.

-

Duplex Stainless Steels (e.g., 2205, 2507): Combining the benefits of austenitic and ferritic stainless steels, duplex grades offer high corrosion resistance, high strength, and good weldability. They are particularly effective in environments prone to stress corrosion cracking and are used in chemical processing, oil and gas exploration, and marine applications.

Stainless Steel Grades ( 400 series)

- Ferritic Stainless Steels (e.g., 409, 410, 420): These grades offer good corrosion resistance, high strength, and are more cost-effective compared to austenitic grades. Ferritic stainless steels are magnetic and have a lower carbon content, which enhances their resistance to stress corrosion cracking. They are commonly used in automotive exhaust systems, industrial equipment, and kitchenware.

- Martensitic Stainless Steels (e.g., 410, 420, 440): Providing high strength and good corrosion resistance, martensitic stainless steels are often used in high-temperature applications. These grades can be heat-treated to achieve various levels of hardness and strength, making them suitable for cutlery, surgical instruments, and turbine blades.

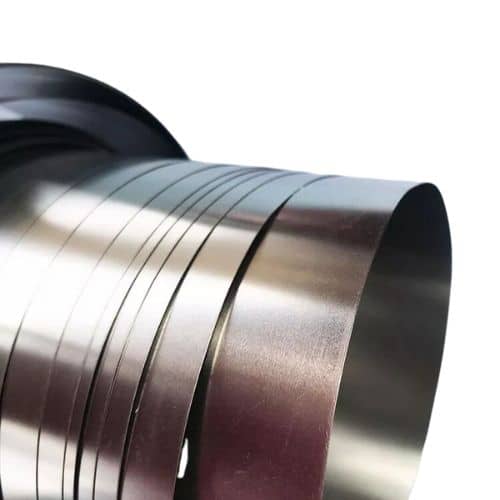

Stainless Steel Coil Finishing Options

- Brushed Finish: Stainless steel coils can be processed to have a brushed look, ideal for decorative purposes.

- Mirror Finish: Achieve a highly reflective, polished surface throughout the roll.

- Bright Annealed Finish: Full rolls of bright annealed stainless steel for a clean, shiny look.

- 2B Surface: Cold-rolled with an original smooth finish.

- Colored Finishes: Options include golden, black mirror, and rose gold brushed surfaces, customizable to your needs

Quality Control and Fabrication

Quality control and fabrication are critical steps in the production of stainless steel coils, ensuring that the final product meets the highest standards. Quality control measures include:

- Raw Material Inspection: Ensuring that raw materials meet specifications and are free from defects. This step is crucial for maintaining the integrity and performance of the final product.

- In-Process Inspection: Monitoring critical parameters during production to ensure that the material meets specifications. This includes checking dimensions, surface finish, and mechanical properties.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, radiographic testing, and eddy current testing are used to detect defects or imperfections without damaging the material. NDT ensures the reliability and safety of the stainless steel coils.

- Mechanical and Chemical Testing: Verifying that the material meets specified mechanical properties, chemical composition, and corrosion resistance requirements. These tests ensure that the stainless steel coils perform as expected in their intended applications.

Fabrication techniques for stainless steel coils include

- Cold Rolling: A process that involves rolling the material at room temperature to achieve the desired thickness and surface finish. Cold rolling enhances the strength and surface quality of the stainless steel coils.

- Heat Treatment: A process that involves heating the material to achieve specific properties, such as hardness or corrosion resistance. Heat treatment can improve the mechanical properties and extend the lifespan of the stainless steel coils.

- Welding: A process that involves joining two or more pieces of stainless steel using heat, pressure, or both. Proper welding techniques ensure strong and durable joints, essential for structural applications.

- Cutting: A process that involves cutting the material to the desired size and shape using techniques such as shearing, sawing, or laser cutting. Precision cutting ensures that the stainless steel coils meet the exact specifications required for various applications.

By adhering to stringent quality control measures and employing advanced fabrication techniques, Daxun ensures that our stainless steel coils meet the highest standards of performance and reliability.

Stainless steel coil processing and customization

We are a manufacturer that provides different processing options for stainless steel coils. We offer finishes like BA finish with PVC/PE, 2B finish with PVC/PE, and No.4 finish with PVC/PE to meet your needs. Our stainless steel coils can also be cut into smaller coils with specific weights to make things easier for you. The inner diameter (ID) of our coils ranges from 150mm to 510mm, and the outer diameter (OD) ranges from 300mm to 1200mm.

Technical Information

At Daxun, we use strong and secure packaging to protect our stainless steel coils. Packaging options include kraft paper, wooden boxes, woven bags, and wooden pallets. Our goal is to ensure your order arrives in perfect condition, ready for use.

All our stainless steel coils meet strict industry standards. We are certified by ISO9001:2008, ISO14001:2014, and other certifications. Our products also comply with the ISO9001:2015 quality management system. You can trust that our coils are produced to high-quality standards.

We ensure our stainless steel coils are the correct weight and quality before shipping. Our testing labs and equipment guarantee this accuracy. Every step of production is carefully inspected by our quality control team to deliver the best possible product.

Our service doesn’t end at delivery. We provide ongoing support even after you receive your order. If you have questions or need assistance, Daxun is here to help. We also offer warranty coverage to give you peace of mind.

Application cases of stainless steel coils in different industries

Stainless steel coils are used for exterior and interior decoration, roofing, and building structures. They combine great looks with high strength to meet various design needs.

Stainless steel is corrosion-resistant, rust-free, and easy to clean, making it ideal for food processing equipment, such as storage tanks, sanitary systems, and fluid pipe tanks.

Thanks to their strength, toughness, and corrosion resistance, stainless steel coils are used in aircraft parts like wings, fuselage supports, and seats.

Our corrosion resistant steel coils are perfect for shipbuilding, thanks to their high strength, toughness, and resistance to seawater corrosion and fatigue. Grades like SS316L are used for marine applications due to their excellent resistance in harsh environments.

echnical Information

- Stock

- Tolerances and Surface

- Production Process

| Thickness (mm) | Width (mm) | Length (mm) | Comment |

| 0.5 | 1000/1219/1500 | C | AAA |

| 0.8 | 1000/1219/1500 | C | AAA |

| 1.0 | 1000/1219/1500 | C | AAA |

| 1.5 | 1000/1219/1500 | C | AAA |

| 2.5 | 1000/1219/1500 | C | AAA |

| 3.0 | 1000/1219/1500 | C | AAA |

| 5.0 | 1500/1800/2000 | C | AAA |

| 6.0 | 1500/1800/2000 | C | AAA |

| 8.0 | 1500/1800/2000 | C | AAA |

| 10.0 | 1500/1800/2000 | C | AAA |

| 12.0+ | 1500/1800/2000 | C | AAA |

| Tolerances | |||||

| Tolerance Rank | |||||

| Size | Group 1 | Group 2 | Group 3 | Delivery State | Surface Condition |

| 0.4 | 0.3 ~ 0.32 | 0.33 ~ 0.37 | 0.37 ~ 0.39 | Cold Rolled | 2B 2D BA Hairline No.3 No.4 6K 8K |

| 0.5 | 0.4 ~ 0.42 | 0.43 ~ 0.47 | 0.47 ~ 0.49 | ||

| 0.6 | 0.5 ~ 0.52 | 0.53 ~ 0.56 | 0.57 ~ 0.59 | ||

| 0.7 | 0.6 ~ 0.62 | 0.63 ~ 0.67 | 0.67 ~ 0.69 | ||

| 0.8 | 0.7 ~ 0.72 | 0.73 ~ 0.77 | 0.74 ~ 0.79 | ||

| 0.9 | 0.8 ~ 0.82 | 0.83 ~ 0.87 | 0.87 ~ 0.89 | ||

| 1 | 0.89 ~ 0.9 | 0.91 ~ 0.94 | 0.94 ~ 0.99 | ||

| 1.2 | 1.02 ~ 1.08 | 1.09 ~ 1.15 | 1.16 ~ 1.18 | ||

| 1.5 | 1.32 ~ 1.38 | 1.39 ~ 1.45 | 1.46 ~ 1.48 | ||

| 2 | 1.72 ~ 1.79 | 1.8 ~ 1.86 | 1.87 ~ 1.9 | ||

| 2.5 | 2.23 ~ 2.36 | 2.32 ~ 2.42 | 1.42 ~ 1.47 | ||

| 3 | 2.7 ~ 2.77 | 2.78 ~ 2.82 | 2.85 ~ 2.9 | ||

| 3 | 2.6 ~ 2.75 | 2.75 ~ 2.85 | 2.86 ~ 2.9 | Delivery State | No.1 No.3 No.4 6K 8K Pickled |

| 4 | 3.5 ~ 3.6 | 3.6 ~ 3.75 | 3.76 ~ 3.95 | ||

| 5 | 4.5 ~ 4.6 | 4.6 ~ 4.75 | 4.75 ~ 4.95 | ||

| 6 | 5.4 ~ 5.6 | 5.6 ~ 5.75 | 5.75 ~ 5.85 | ||

| 8 | 7.3 ~ 7.5 | 7.5 ~ 7.65 | 7.65 ~ 7.85 | ||

| 10 | 9.2 ~ 9.3 | 9.3 ~ 9.6 | 9.6 ~ 9.85 | ||

| 12 | 11.1 ~ 11.2 | 11.2 ~ 11.6 | 11.6 ~ 11.85 | ||

| 14 | 13.1 ~ 13.2 | 13.2 ~ 13.6 | 13.6 ~ 13.85 | ||

| Note: 1. If you require different deliver state than the above listed, kindly confirm with us. 2. In case of any enquiry or order, please kindly let us know any extra requirement not indicated here. |

|||||

Why Choose Daxun?

- Large Inventory: With 30,000 tons in stock, we can meet your needs quickly.

- Quality Assurance: Our products are certified and meet strict quality standards.

- Custom Solutions: We offer a variety of finishes, custom sizes, and free samples to ensure you get exactly what you need.

- After-Sales Service: We provide ongoing support, including warranty coverage, even after delivery.

Yes, we have a wide range of stainless steel coils in stock.

Absolutely. We offer customizations to meet your specific requirements.

We use sea and land transportation to ensure your products arrive safely and quickly.

Yes, we offer free samples for you to check the quality; you just pay for the shipping.