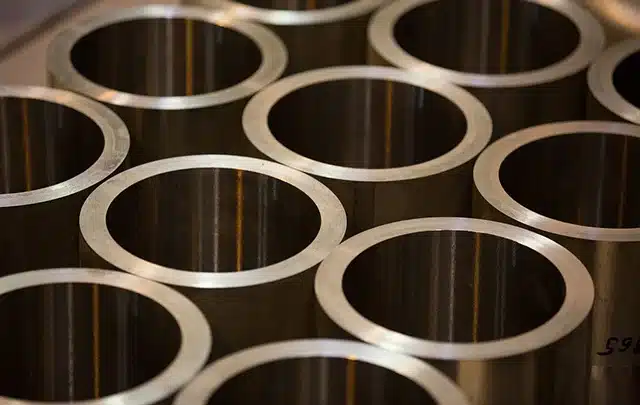

Daxun Alloy - труба Hastelloy C-4, произведенная в Китае

Являясь ведущим поставщиком труб из сплава Hastelloy C-4 в Китае, компания Daxun поставляет трубы из этого сплава с высокими эксплуатационными характеристиками по всему миру.

- Hastelloy C-4 types: Seamless tube, welded tube, forged tube

- Сертификация: ASTM,SGS,ISO,CE

- Срок поставки: 7-15 дней

- Поверхностная обработка: отожженная, полированная и т. д.

- Минимальный заказ: ≥300 кг

————Daxun производит трубы из хастеллоя в Китае для удовлетворения разнообразных и требовательных потребностей клиентов!

Характеристики и свойства Hastelloy C-4

Hastelloy C-4 (UNS N06404) — это высокопроизводительный коррозионно-стойкий сплав серии никель-хром-молибден (Ni-Cr-Mo), разработанный американской компанией Hastelloy Alloy Company (Haynes International), и представляет собой улучшенную версию серии Hastelloy C, стабилизированную низкоуглеродистым титаном. Пластина Hastelloy C-4 — это конструкционный материал, разработанный для обеспечения стойкости к высокотемпературной коррозии. Его титановая стабилизация + сверхнизкоуглеродистый состав решают проблему сенсибилизации традиционных сплавов на основе никеля. Он особенно подходит для сварки деталей и высокотемпературных и высококоррозионных сред, и незаменим в областях химической промышленности, энергетики и т. д.

Коррозионная стойкость:

Отличная стойкость к коррозионному растрескиванию под напряжением под действием хлоридов (SCC).

Устойчив к сильным окислительным средам (таким как азотная кислота, хромовая кислота) и восстановительным средам (таким как серная кислота, соляная кислота).

Устойчив к коррозии, такой как влажный хлор, гипохлорит, диоксид хлора и т. д.

Термическая стабильность:

Отсутствие осаждения вредной фазы в диапазоне 650-1040 ℃, что позволяет избежать межкристаллитной коррозии.

Механические свойства:

Хорошая прочность при высоких температурах, подходит для сред с высокой температурой и высоким давлением.

Хорошая пластичность и вязкость, легко обрабатывается и формуется.

Типичные области применения

Химическая промышленность: реакторы, теплообменники, системы трубопроводов (особенно в средах с хлорид-ионами).

Экологическая инженерия: системы десульфурации дымовых газов (FGD), оборудование для очистки сточных вод.

Нефть и природный газ: добыча кислой нефти и газа (устойчив к коррозии H₂S и CO₂).

Фармацевтическая промышленность: производственное оборудование для сильных кислотных сред.

Атомная промышленность: контейнеры для едких сред при переработке ядерного топлива.

Обработка и сварка

Горячая обработка: рекомендуется нагревать до 1100-1200 ℃ для ковки или прокатки и избегать длительного нахождения в диапазоне 700-900 ℃.

Холодная обработка: требуется промежуточный отжиг для устранения напряжений, а температура отжига обычно составляет 1120-1170 ℃.

Сварка: применимо к TIG, MIG, дуговой сварке и т. д., рекомендуется использовать соответствующие сварочные материалы (например, сварочную проволоку HC-4). Как правило, после сварки термообработка не требуется.

Параметры сплава Хастеллой С-4

- Химический состав

- Физические свойства

- Механические свойства

| Ni | Cr | Mo | Fe | Co | C |

| ≥65% | 14.0 – 18.0 | 14.0 – 17.0 | ≤3.0 | ≤2.0 | ≤0.015 |

| Si | Mn | Ti | W | P | S |

| ≤0.08 | ≤1.0 | ≤0.70 | ≤0.50 | ≤0.025 | ≤0.010 |

| Свойство | Плотность | Температура плавления | Коэффициент теплового расширения (20-100°C) | Теплопроводность (20°C) | Удельное электрическое сопротивление (20°C) | Магнитная проницаемость |

| Ценить | 8,64 г/см³ | 1350 – 1400°C | 12,6 мкм/м·°C | 10,1 Вт/м·К | 1.25 μΩ·m | Немагнитный (<1,001) |

| Свойство | Предел прочности на растяжение (UTS) | Предел текучести (смещение 0,2%) | Удлинение | Твёрдость (по Бринеллю, HB) | Модуль упругости |

| Ценить | ≥690 МПа | ≥310 МПа | ≥40% | ≤220 | 210 ГПа |

Выберите Daxun, чтобы помочь вашему проекту набрать обороты.

Расширенное производство:труба из сплава Хастеллой

Сплав Hastelloy C4 представляет собой универсальный сплав никеля, хрома, молибдена и вольфрама с хорошей устойчивостью к точечной коррозии, щелевой коррозии и коррозионному растрескиванию под напряжением. Он обладает превосходной устойчивостью к окислительным водным средам, включая влажный хлор, азотную кислоту или смешанные кислоты окисляющих кислот, содержащие хлорид-ионы. В то же время сплав Hastelloy C4 также обладает идеальной устойчивостью к восстановительным и окислительным средам, встречающимся в процессе. Благодаря этим универсальным характеристикам его можно использовать в некоторых сложных средах или на заводах для различных производственных целей.

Характеристики трубы Hastelloy C-4

Сплав Hastelloy C4 обладает исключительной стойкостью к различным химическим средам, включая сильные окислители, такие как хлорид железа, хлорид меди, хлор, термически загрязненные растворы (органические и неорганические), муравьиная кислота, уксусная кислота, уксусный ангидрид, морская вода и солевые растворы и т. д. Сплав Hastelloy C4 обладает способностью противостоять образованию осадков по границам зерен в зоне термического влияния сварки, благодаря чему его также можно использовать во многих химических процессах в состоянии сварки.

Quality, delivery, inspection

Daxun проводит ряд испытаний на качество труб Hastelloy C-4. Эти испытания включают испытание на сплющивание, испытание на развальцовку, ультразвуковую дефектоскопию, испытание на стойкость к щелевой коррозии, испытание на механические свойства, испытание на твердость, положительную идентификацию материала, испытание на расширение и т. д. Все эти испытания предназначены для того, чтобы гарантировать, что трубы Hastelloy C-4 соответствуют требованиям предполагаемого применения. В процессе производства мы тщательно измеряем внешний диаметр, толщину стенки и качество поверхности изделий. Наш стандартный срок поставки составляет 5–7 дней, а для специальных размеров — 15–20 дней.

- Наши сроки поставки строго соответствуют контракту.

- Поддержка сторонних агентств клиентов для посещения завода для проверки

- Поддержка бесплатных образцов для тестирования клиентами

- Поддержка выездной или видеоинспекции завода

Упаковка

Daxun Alloy гарантирует наилучшее качество упаковки, поскольку она играет важную роль в международных грузоперевозках, где товары проходят через различные каналы, чтобы достичь конечного пункта назначения, поэтому мы уделяем особое внимание упаковке. Мы упаковываем наши товары разными способами в зависимости от продукта. Мы упаковываем наши продукты разными способами, такими как:

•Коробки и ящики

• Термоусадочная пленка

• Деревянные поддоны

• Деревянные ящики

Техническая поддержка

Если вам нужна дополнительная техническая помощь, наш местный металлург и знающий персонал будут рады помочь. [Свяжитесь с нами сейчас]Кроме того, Daxun может похвастаться сертифицированной испытательной лабораторией — первой в отрасли многометаллического и пластикового инвентаря. Это, по нашему мнению, демонстрирует нашу непоколебимую преданность качеству и нашу философию как поставщика полного спектра услуг.

Daxun — надежный производитель труб из нержавеющей стали.

Как профессиональный производитель, Daxun гарантирует, что вся производимая нами продукция отличается высоким качеством. Поэтому мы гарантируем, что все титановые трубы сертифицированы по стандартам ISO9001, SGS, CE, OQC и другим международным стандартам качества. Мы также проводим строгий контроль качества, чтобы гарантировать, что у труб из нержавеющей стали будет меньше дефектов. В Daxun вы можете быть уверены, что вся продукция долговечна, качественна и имеет превосходные эксплуатационные характеристики.

Сопутствующие товары (8)

Пожалуйста, заполните форму на странице «Связаться с нами» или позвоните нашему менеджеру по продажам по телефону «+86 13382898899», мы свяжемся с вами как можно скорее. Наш WhatsApp в сети, а электронная почта ([email protected]) будет проверена в течение 6 часов. На каждый запрос или сообщение будет дан оперативный ответ. Кроме того, мы каждую неделю делимся рыночной информацией с нашими клиентами

Мы можем предоставить образцы листов нержавеющей стали для проверки качества. Образец бесплатный, вы платите только за доставку.

Мы экспортируем продукцию в более чем 42 страны, такие как Канада, Чили, Кувейт, Германия, Южная Корея, Саудовская Аравия, Сингапур и т. д.

Минимальный объем заказа для нашей продукции из Хастеллоя составляет 300 кг.

Пробные заказы могут быть доставлены в течение недели. Для обычных заказов это занимает около двух недель.