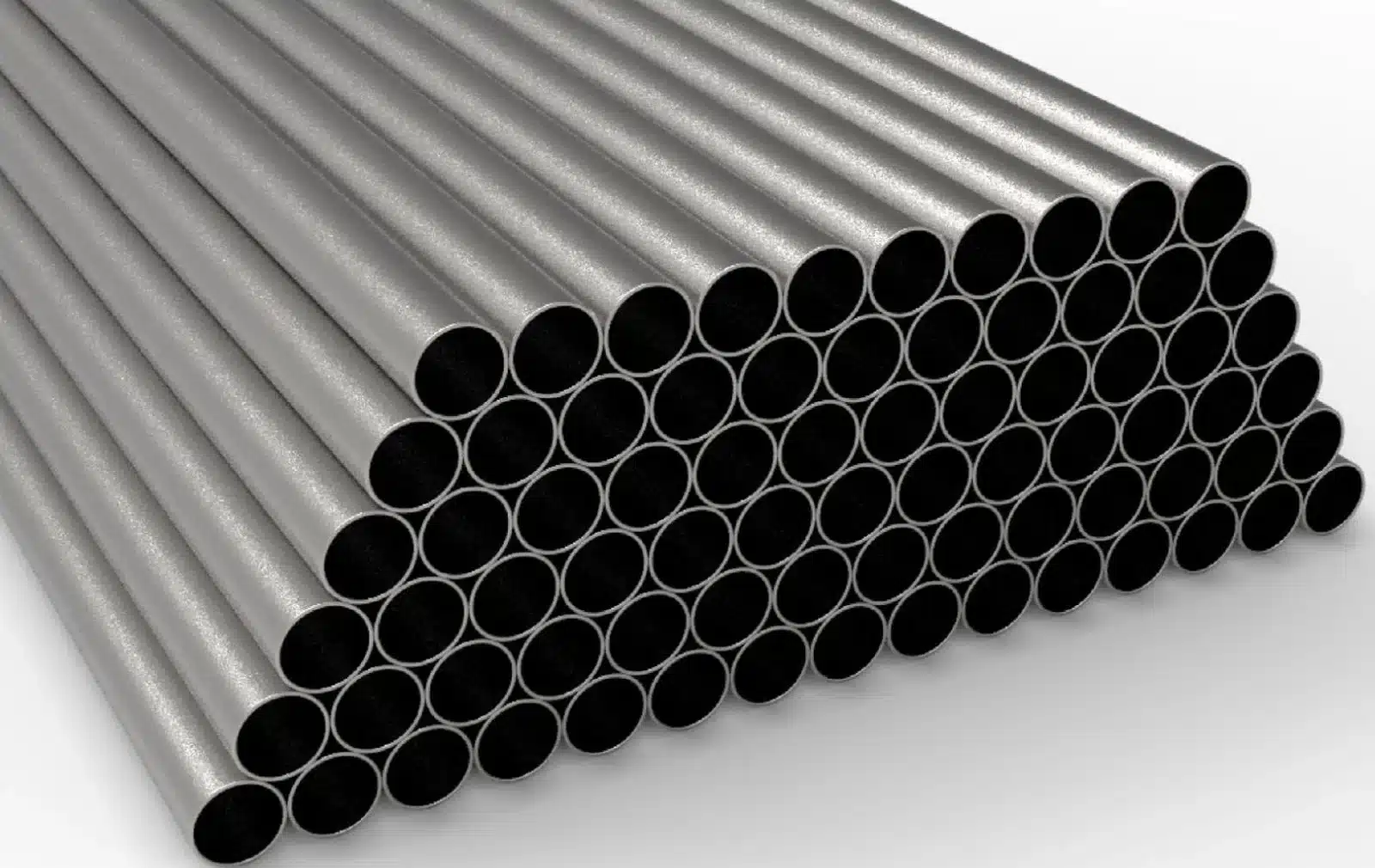

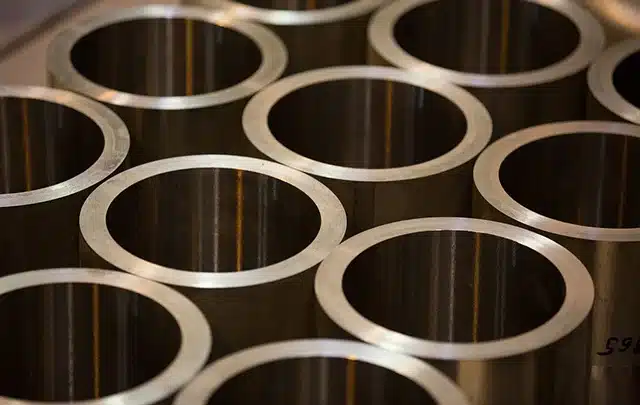

Daxun Alloy - труба Hastelloy B3, произведенная в Китае

Являясь ведущим поставщиком труб из сплава Hastelloy B3 в Китае, компания Daxun поставляет трубы из этого сплава с высокими эксплуатационными характеристиками по всему миру.

- Типы Hastelloy B3: бесшовная труба, сварная труба, кованая труба

- Сертификация: ASTM, SGS, ISO, CE

- Срок доставки: 7-15 дней

- Обработка поверхности: отжиг, полировка и т.д.

- Минимальный заказ: ≥300 кг

————Daxun производит трубы из хастеллоя в Китае для удовлетворения разнообразных и требовательных потребностей клиентов.!

Характеристики и свойства Hastelloy B3

Труба Hastelloy B3 (N10675) представляет собой жаропрочный сплав на основе никеля, состоящий из никеля, молибдена, кобальта и других элементов, с содержанием никеля около 65%. Материал сплава на основе никеля Hastelloy B3 (N10675) представляет собой новый материал, улучшенный на основе Hastelloy B2, который повышает термическую стабильность материала, тем самым улучшая коррозионную стойкость, и в то же время улучшает свойства горячей и холодной формовки.

Коррозионная стойкость: Hastelloy B3 обладает превосходной коррозионной стойкостью к соляной кислоте при любой температуре и концентрации, а также хорошей коррозионной стойкостью к неокисляющим средам, таким как серная кислота, уксусная кислота, муравьиная кислота, фосфорная кислота и т. д. Его термическая стабильность значительно улучшена по сравнению с B2, и он обладает высокой стойкостью к точечной коррозии, коррозионному растрескиванию под напряжением, ножевой коррозии и коррозии в зоне термического влияния сварки.

Механические свойства: прочность на разрыв Hastelloy B3 обычно составляет от 690 до 860 МПа, предел текучести обычно составляет от 310 до 550 МПа, удлинение обычно составляет от 40% до 50%, а твердость обычно составляет от 20 до 30 единиц твердости по Роквеллу (HRC).

Характеристики обработки формованием: Hastelloy B3 имеет высокое удлинение, что создает благоприятные условия для холодной формовки. Однако, поскольку он тверже аустенитной нержавеющей стали и имеет более очевидную тенденцию к упрочнению, он требует большего давления или пошаговой формовки во время холодной формовки. Когда скорость деформации холодной формовки составляет менее 10%, это не повлияет на коррозионную стойкость заготовки, но наличие остаточного напряжения может вызвать термические трещины в сварном шве во время сварки.

Hastelloy B3 широко используется в областях химического, нефтехимического, энергетического производства и контроля загрязнения, особенно в таких отраслях, как H2SO4, HCl, H3PO4, CH3COOH и т. д. Он используется для изготовления ключевого оборудования, такого как реакторы, теплообменники, трубопроводы и клапаны. Благодаря своей превосходной стойкости к коррозии соляной кислотой это оборудование может стабильно работать в течение длительного времени в среде с высокой концентрацией соляной кислоты.

Характеристики сварки: Hastelloy B3 можно сваривать всеми распространенными методами сварки, но рекомендуется метод сварки GTAW. Сварочные материалы ERNiMo-10 следует выбирать в соответствии со стандартами ASME ⅡSFA-5.14/SFA-5.14M. Перед сваркой канавку и сварочные материалы следует очистить, а во время сварки следует использовать небольшую линейную энергию, чтобы предотвратить чрезмерное поступление тепла.

Параметры Хастеллоя B3

- Химический состав

- Физические свойства

- Механические свойства

| C≤ | Si≤ | Mn≤ | P≤ | S≤ | Cr≥ | Ni≥ | Mo≥ | Cu≤ |

| 0.01 | 0.1 | 3 | 0.03 | 0.01 | 1.00-3.00 | 65 | 27.0-32.0 | 0.2 |

| Nb/Ta≤ | Al≤ | Ti≤ | Fe≤ | Co≤ | V≤ | W≤ | Ni+Mo | Ta≤ |

| 0.2 | 0.5 | 0.2 | 1.00-3.00 | 3 | 0.2 | 3 | 94.0-98.0 | 0.2 |

| Плотность | 9,22 – 9,24 г/см³ |

| Температура плавления | 1370 – 1418°C |

| Thermal expansion coefficient | Приблизительно 0,6 мкм/м°C (20-100°C) |

| Теплопроводность | Около 10 Вт/м·К |

| Предел прочности | 690 – 860 MPa |

| Предел текучести | 310 – 550 MPa |

| Elongation | 40% – 50% |

| Твёрдость | Твёрдость по Роквеллу 20-30 (HRC) |

Выберите Daxun, чтобы помочь вашему проекту набрать обороты.

Расширенное производство:труба из сплава Хастеллой

- Бесшовные трубы Hastelloy B3 подвергаются горячей прокатке или горячей экструзии, выпрямлению, обработке с внутренним и внешним диаметрами и поверхностной обработке. Трубы могут поставляться в термообработанном или нетермообработанном виде. Daxun имеет 100% возможности ультразвукового контроля.

- Горячекатаная труба/горячепрессованная бесшовная труба из сплава Hastelloy B3: наружный диаметр от 1,0 мм до 325 мм, толщина стенки от 0,3 мм до 50 мм, длина до 12000 мм.

- Холоднокатаная бесшовная труба из сплава Hastelloy B3: Холоднообработанные трубы поставляются после термической обработки, поверхностной обработки, гидростатического испытания или ультразвукового контроля в соответствии с требованиями производственной спецификации. Наружный диаметр от 6 мм до 102 мм, толщина стенки от 0,5 мм до 20 мм, длина до 9000 мм.

Характеристики труб Hastelloy B3

Труба Hastelloy B3 — это труба из сплава на основе никеля. Поскольку она содержит большое количество никеля, молибдена и других элементов, она устойчива к различным сильным кислотным коррозиям и обладает определенными высокотемпературными характеристиками. Она изготавливается по специальной технологии и широко используется в трубопроводной транспортировке в химических, морских, экологических и других средах с сильными коррозионными средами.

- Отличная коррозионная стойкость

- Высокая температурная стабильность

- Хорошая производительность обработки

- Высокая прочность и ударная вязкость

Качество, доставка, проверка

Daxun проводит ряд испытаний на качество труб Hastelloy B3. Эти испытания включают испытание на сплющивание, испытание на развальцовку, ультразвуковую дефектоскопию, испытание на стойкость к щелевой коррозии, испытание на механические свойства, испытание на твердость, положительную идентификацию материала, испытание на расширение и т. д. Все эти испытания предназначены для того, чтобы гарантировать, что трубы Hastelloy B3 соответствуют требованиям предполагаемого применения. В процессе производства мы тщательно измеряем наружный диаметр, толщину стенки и качество поверхности изделий. Наш стандартный срок поставки составляет 5–7 дней, а для специальных размеров — 15–20 дней.

- Наши сроки поставки строго соответствуют договору

- Поддержка сторонних агентств-клиентов при посещении завода для проведения инспекции

- Поддержка бесплатных образцов для тестирования клиентами

- Поддержка инспекции завода на месте или видеоинспекции

Упаковка

Daxun Alloy гарантирует наилучшее качество упаковки, поскольку она играет важную роль в международных грузоперевозках, где товары проходят через различные каналы, чтобы достичь конечного пункта назначения, поэтому мы уделяем особое внимание упаковке. Мы упаковываем наши товары разными способами в зависимости от продукта. Мы упаковываем наши продукты разными способами, такими как:

• Коробки и ящики

• Термоусадочная пленка

• Деревянные поддоны

• Деревянные ящики

Техническая поддержка

Если вам нужна дополнительная техническая помощь, наш местный металлург и знающий персонал будут рады помочь. Кроме того, Daxun может похвастаться сертифицированной испытательной лабораторией — первой в отрасли многометаллического и пластикового инвентаря. Это, по нашему мнению, демонстрирует нашу непоколебимую приверженность качеству и нашу философию как поставщика полного спектра услуг.

Daxun — надежный производитель труб из сплава хастеллоя.

Как профессиональный производитель, Daxun гарантирует, что вся производимая нами продукция отличается высоким качеством. Поэтому мы гарантируем, что все титановые трубы сертифицированы по стандартам ISO9001, SGS, CE, OQC и другим международным стандартам качества. Мы также проводим строгий контроль качества, чтобы гарантировать, что у труб из нержавеющей стали будет меньше дефектов. В Daxun вы можете быть уверены, что вся продукция долговечна, качественна и имеет превосходные эксплуатационные характеристики.

Сопутствующие товары (8)

Пожалуйста, заполните форму на странице «Связаться с нами» или позвоните нашему менеджеру по продажам по телефону «+86 13382898899», мы свяжемся с вами как можно скорее. Наш WhatsApp в сети, а электронная почта ([email protected]) будет проверена в течение 6 часов. На каждый запрос или сообщение будет дан оперативный ответ. Кроме того, мы каждую неделю делимся рыночной информацией с нашими клиентами

Мы можем предоставить образцы листов нержавеющей стали для проверки качества. Образец бесплатный, вы платите только за доставку.

Мы экспортируем продукцию в более чем 42 страны, такие как Канада, Чили, Кувейт, Германия, Южная Корея, Саудовская Аравия, Сингапур и т. д.

Минимальный объем заказа для нашей продукции из Хастеллоя составляет 300 кг.

Пробные заказы могут быть доставлены в течение недели. Для обычных заказов это занимает около двух недель.