Super Austenitic 904l Stainless Steel Coil China Supplier

As a leading stainless steel coil supplier and exporter in China, Daxun supplies stainless steel coils to all over the world.

- Coil grade: 904L-N08904

- Stronger corrosion properties than Type 316L an 317L

- Good resistance to sulphuric, phosphoric and acetic acids

- High resistance to crevice and stress corrosion cracking

- Excellent formability and weldability

Global leader in stainless steel Coil fabrication services

Type 904L is a high alloy austenitic stainless steel that is renowned for its corrosion resistance. 904L alloy (UNS N08904) is a super austenitic stainless steel that may be used in a variety of process settings and has moderate to high corrosion resistance. The high chromium and nickel content, along with molybdenum and copper, ensures good to outstanding corrosion resistance. With a highly alloyed chemistry (25% nickel and 4.5% molybdenum), 904L offers better resistance to chloride stress corrosion cracking, pitting, and general corrosion than 316L and 317L molybdenum reinforced stainless steels. The 904L alloy was originally created to withstand dilute sulfuric acid conditions. It is also resistant to most organic acids and other inorganic acids, including hot phosphoric acid. 904L alloy is easily weldable and may be handled using typical shop fabrication procedures.

Dah Hsun is an ISO 9001:2008 certified firm that is a major supplier and exporter of ASTM A240 Stainless Steel Coils. Stainless steel coils can be cut to your requirements and include a full set of mill test results. Custom lengths and widths are available up to 2000mm. Exporting is our specialty! We can obtain several hard-to-find grades and/or non-standard sizes to satisfy our customers’ specific needs. We have vast experience processing steel coil goods and can divide all stainless steel coils to the desired sizes. Introducing our extensive line of Dah Hsun Stainless Steel goods – the pinnacle of dependability, durability, and performance. We are glad to provide a wide selection of grades and varieties to fulfill the diverse needs of industrial and architectural applications.

Our stainless steel coil goods, which range from the Austenitic series to the Ferritic series and other special categories, are well-known for their high performance and extensive requirements. The austenitic series includes 304/304L/304J1, 321 and 316/316L/317L/316Ti/310/309, which can fulfill varied thickness requirements and give a variety of surface treatments, including 2B, BA, NO.4, 8K, SB, HL, NO.1, and so on.

Our ferrite line, which includes 430, ultra-pure ferrite 443, and 436L/439/444/441, caters to customers looking for unique qualities and applications. These materials can accommodate thicknesses ranging from 0.4mm to 3.0mm and offer a variety of surface treatment options such as 2B, BA, NO.4, 8K, SB, HL, and so on.

By selecting our stainless steel coils, you are investing in a material that ensures long service life, great reliability, and exceptional performance. Don’t compromise on quality; choose our stainless steel solutions and see the impact they can make in your project. Contact Daxun today for additional information or to place an order for the stainless steel coil specs and quantities that you require.

Data

- Parameter

- Element

- Mechanical Properties

- PHYSICAL PROPERTIES

- All equivalent

- 904L coil stock

| 904L Stainless Steel Coil Specification | ASTM A240 / ASME SA240 |

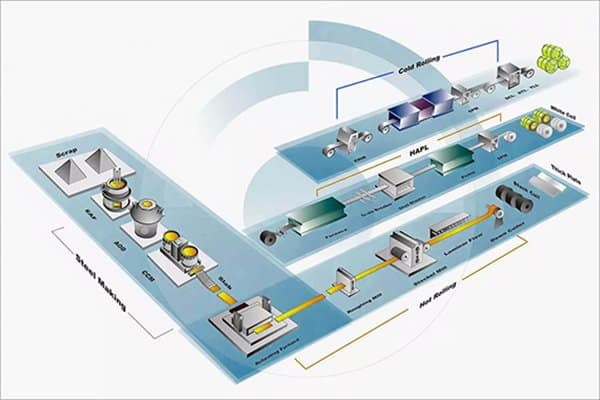

| 904L Stainless Steel Coil Manufacturing Process | Hot Rolled (HR) / Cold Rolled (CR) |

| 904L Stainless Steel Coil Grades | 201 / 304 / 304L/ 904L / 309S / 420 / 316 / 316L / 316Ti / 317L / 321 / 321H / 347 / 347H / 904L etc. |

| UNS No. – UNS S904L, UNS S31008, UNS S31600, UNS S31603, UNS S31603, UNS S31600, UNS S31703, UNS S32100, UNS S34700, UNS S34709, UNS S8904 | |

| EN No. 1.4845, 1.4401, 1.4404, 1.4571, 1.4438, 1.4541, 1.4550, 1.4551, 1.4539 | |

| 904L Stainless Steel Coil Thickness | 0.6 MM TO 16 MM THICKNESS |

| 904L Stainless Steel Coil Width | 1250 MM / 1500 MM / 2000 MM / 04 Feet / 05 Feet and Custom Cut Width as Per Requirement |

| 904L Stainless Steel Coil Length | 2400 MM / 2420 MM / 6000 MM / 08 Feet / 10 Feet / Coil Cut and Custom Cut Length as Per Requirement |

| 904L Stainless Steel Coil Surface Finish | 2B, 2D, BA, MATT, MATT PVC, No.4, No.5, SB, HR, No.8, Mirror, Hairline, Brush, Textured, Oil base wet Polished, Both sides Polished available. |

| 904L Stainless Steel Coil Coating | PVC coating Normal / Laser, Film: 100 micrometer, Color: black/white. |

| 904L Stainless Steel Coil Other Testing | NACE MR0175, Ultrasoung TEST, IGC TEST, Intergranular Corrrosion Test as per ASTM A262 Practice E, Charpy Impact Test, Macro, Grain Size, Hardness, etc. |

| 904L Stainless Steel CoilValue Added Services | Gas Cutting / CNC Plasma Cutting / Profiling / Rolling / Bending / coil Metal Fabrication / Drill / Punch / Machining / Sand Blasting / Shot Blasting / Heat Treatment |

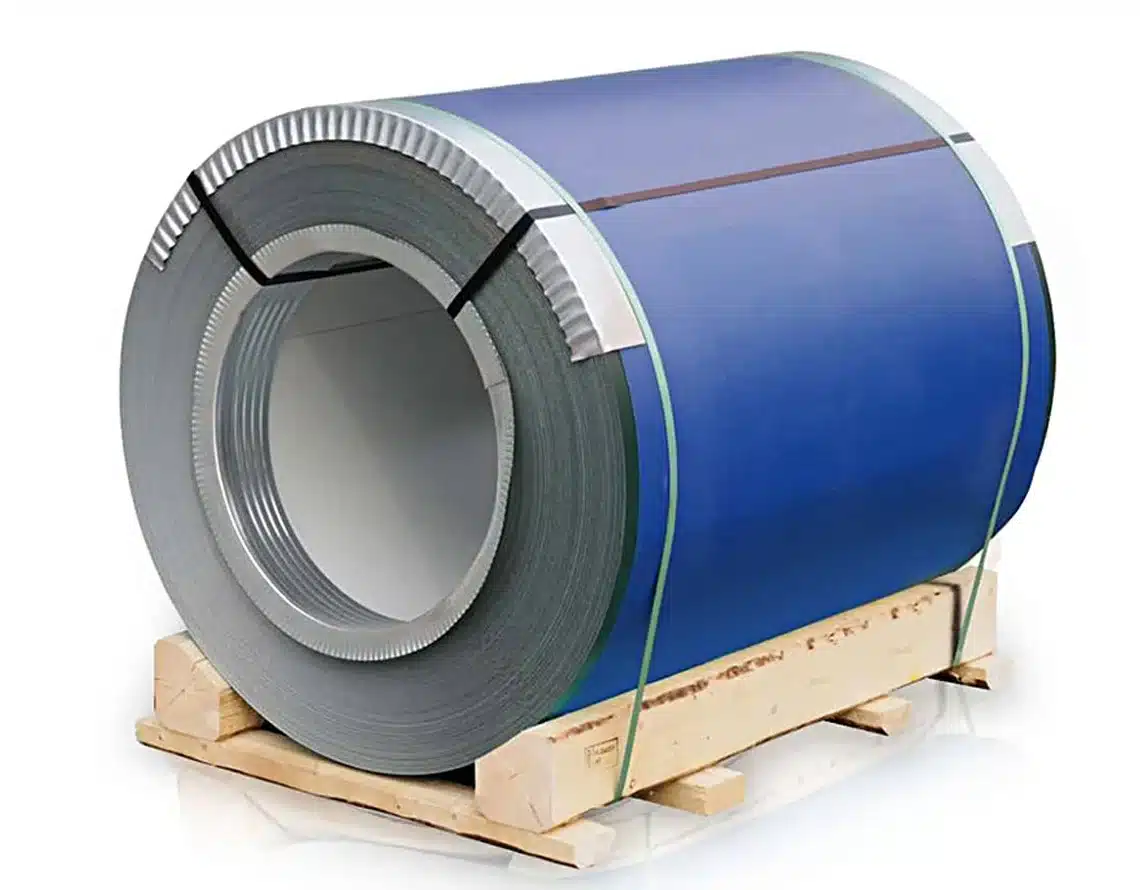

| 904L Stainless Steel Coil Packaging | Loose / Carrate / Wooden Pallet / Wooden box-a / Plastic Cloth Wraps |

| 904L Stainless Steel Coil Shipment & Transportation | By Road – Truck / Train Partial Load, Full Load, By Sea – Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air – Freighter Civil Passenger and Cargo Planes |

| 904L Stainless Steel Coil Material Test Certificate | Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS, Bureau of Indian Standards BIS Approved ETC |

| Manufacturer | POSCO, Aperam, Jindal Stainless, DKC Korea, Thyssenkrup, Baosteel, TISCO,Arcelor Mittal, VDM,Nippon Metal, Outokumpu,Qingshan,Delong. |

| Shipping Port | Shanghai/Ningbo port/Tianjin/Qindao |

| Element | % Present (in product form) |

| Carbon (C) | 0.02 |

| Silicon (Si) | 0.7 |

| Manganese (Mn) | 2 |

| Phosphorous (P) | 0.03 |

| Sulfur (S) | 0.01 |

| Chromium (Cr) | 19.00 – 21.00 |

| Nickel (Ni) | 24.00 – 26.00 |

| Nitrogen (N) | 0.15 |

| Molybdenum (Mo) | 4.00 – 5.00 |

| Copper (Cu) | 1.20 – 2.00 |

| Iron (Fe) | Balance |

| Yield Strength | Ultimate Tensile | Elongation | Hardness | ||

| 0.2% Offset | Strength | in 2 in. | |||

| psi (min.) | (MPa) | psi (min.) | (MPa) | % (min.) | (max.) |

| 31,000 | 220 | 71,000 | 490 | 36 | 70-90 Rockwell B |

| Reference data on some physical properties | ||

| Density at 20°C kg/m3 | 8 | |

| Thermal Conductivity W/m K at | 20°C | 12 |

| Modulus of Elasticity kN/mm2 at | 20°C | 195 |

| 200°C | 182 | |

| 400°C | 166 | |

| 500°C | 158 | |

| Specific Thermal Capacity at 20°C J/kg K | 450 | |

| Electrical Resistivity at 20°C Ω mm2/m | 1 | |

| STANDARD | WERKSTOFF NR. | UNS | JIS | AFNOR | BS | GOST | EN |

| SS 904L | 1.4539 | N08904 | SUS 904l | Z2 NCDU 25-20 | 904S13 | – | X1NiCrMoCu25-20-5 |

| • 904L Stainless Steel HR coil | • Baosteel Stainless Steel 904L coil |

| • 904L Stainless Steel Chequered coil | • Stainless Steel Cladding 904L coil |

| • 904L Stainless Steel Golden Laser Pattern coil | • Black SS 904L coil 4mm Thick |

| • Super thin-Mirror surface BA ss 904L coil | • Bright-pickled Stainless Steel 904L coil |

| • Super Austenitic SS 904L coil | • Cold rolled, heat treated 904L coil |

| • ASTM A240 904L coil | • 3mm Cold Rolled AISI SS 904L coil |

| • JMSS cold rolled ss 904L coil | • Mill Supply SS 904L coil |

| • Cold Rolled No.1 Finish SS 904L coil | • Grade Prime SS 904L coil |

| • SEW 400 Stainless Steel 904L coil | • Carpenter Custom 450 Stainless Steel 904L coil |

| • Hot Rolled Stainless Steel 904L coil | • Cut to Size Stainless Steel 904L coil |

| • Sales Promotion SS 904L coil | • Non Magnetic Polishing Stainless Steel 904L coil |

| • Cr Stainless Steel 904L coil | • ASME SA240 904L coil |

| • SS 904L Mill Test Certificate coil | • Grade 904L Stainless Steel Finish coil |

| • ASTM A240 904L coil | • 904L Stainless Steel Blank coil |

| • Cold rolled, bright annealed 904L coil | • 904L Stainless Steel Perforated coil |

| • Ground Stainless Steel 904L coil | • Embossed ss 904L coil |

| • Hot Selling AISI SS 904L coil | • Cheap cold rolled ss 904L coil with best price |

| • SS 904L Rose Golden coil | • Brush finish ss 904L coil price list |

| • Surface coated Stainless Steel 904L coil | • SS URANUS B6 904L coil |

| • Satin finish Stainless Steel 904L coil | • 2B SUS SS 904L coil |

| • AISI stainless steel 904L armor coil | • Food Grade Stainless Steel 904L coil |

| • Satin finish Stainless Steel 904L coil | • No. 4 PVC Coated SS 904L coil |

| • Mirror Finish SS 904L coil | • SS 904L coil Blasted Tin-Gold Rose |

| • SS 904L coil Gold Brush Finish | • 2mm ASTM SS 904L coil |

| • 904L Stainless Steel CR coil | • Stainless Steel Corrugated 904L coil |

| • 904L Stainless Steel 2B coil | • ASTM A240 904L coil |

| • 904L Stainless Steel B. Q. Profile coil | • Brushed or dull polished Stainless Steel 904L coil |

| • Best selling 4’x8′ mirror finished ss 904L coil | • Cold rolled, heat treated, pickled 904L coil |

| • Decorative hairline inox cold rolled ss 904L coil | • 10K Mirror Finish Surface SS 904L coil |

| • Hair Line Finish SS 904L coil | • Gold Etched SS 904L coil |

| • Laser cutting ss 904L coil | • 18 Gauge SS 904L coil |

| • Tisco Supplier 3mm Thickness Stainless Steel 904L coil | • Patterned Stainless Steel 904L coil |

| • Decorative Stainless Steel 904L coil | • Patterned Stainless Steel 904L coil |

| • Scotch Brite SS 904L coil | • Passenger Elevator Cabin SS 904L coil |

Choose Daxun and make your customers satisfied.

Quick response 904L Stainless Steel coil

We provide timely and fast delivery of stainless steel products for customers with urgent needs. Behind the speed is the system support from information flow to logistics and capital flow. For example, in terms of information flow, Daxun’s order data is pushed to the logistics system in real time, and the data is seamlessly connected; in terms of logistics, the processing center is close to highways and rivers and seas, with reasonable scheduling, rapid response, storage and transportation linkage, and efficient loading, ensuring that the task is completed on schedule.Daxun’s stainless steel materials are of reliable quality, and their varieties, specifications and delivery weights strictly comply with the standards.

Daxun Advantages

Quality is belief, and integrity is a business card. Daxun pioneered the concept of “performance excellence management” and implemented the “PDCA+Lean” management model. The company’s business card says “Daxun = assured quality”. Daxun Stainless Steel achieves full traceability of each steel plate from the ERP system, including variety, specification, and origin, and advocates and encourages industry anti-counterfeiting. Daxun Stainless Steel relies on technology for processing and customization, and high precision and high quality are the industry benchmarks; in terms of service, it promotes product life cycle management, provides professional material selection and processing solutions before sales, strict monitoring during sales, and provides worry-free service guarantees after sales.

904L Stainless Steel coil Packaging

Daxun Alloy ensures the best quality of packaging as it plays an important role in international freight where goods go through various channels to reach the final destination, so we pay special attention to packaging. We pack our goods in many ways depending on the product. We pack our products in many ways such as:

• Boxes and crates

• Shrink wrap

• Wooden pallets

• Wooden boxes

Quality, delivery, inspection

- Daxun also conducts several quality assurance tests. These tests include flattening test, pitting and resistance test, mechanical test, hardness test, material positive identification, expansion test, etc. All these tests ensure that the material is suitable for the required application.

- During the production process, we measure the diameter, thickness, and surface of the product. Our standard delivery time is 7-15 days, except for some special size products, our delivery time will increase to 20 days.

Our delivery time is strictly in accordance with the contract. - Support customer third-party agencies to go to the factory for inspection

- Support free samples to customers for testing

- Support on-site or video factory inspection

904L Stainless Steel coil Ordering Information

Purchase orders should include quantity, grade, type or category, API5L reference, thickness, width, length, and any applicable attachments or additional requirements related to chemical composition, mechanical properties, heat treatment, additional testing, manufacturing process, surface coating or end finish. Contact Daxun now, we will reply to your email as soon as possible.

Technical Support

If you need any additional technical assistance, our resident metallurgist and knowledgeable staff will be pleased to help. Additionally, Daxun boasts a certified testing laboratory—a first in the multi-metal and plastic inventory industry. This, in our opinion, demonstrates our unwavering dedication to quality and our philosophy as a full-service supplier.

904L Stainless Steel Coil Features

Daxun Alloy Let your brand improve rapidly

- Gallery

- Product Series

- Main Equipment

| Grade | Type | Thickness | Surface |

| Austenitic | 304/304H/304L/304J1 | 0.25-150mm | 2B/BA/NO.4/8K/SB/HL/NO.1 |

| 321 | 0.4-80mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| 316/316L/317L/316Ti | 0.3-80mm | 2B/BA/NO.4/8K/SB/HL/NO.1 | |

| Ferrite | 430 | 0.4-3.0mm | 2B/BA/NO.4/8K/SB/HL |

| Ultra Pure Ferrite | 443 | 0.4-2.0mm | 2B |

| 436L/439/444/441 | 0.5-3.0mm | 2B、2D | |

| 409L | 0.4-2.5mm | 2B、2D | |

| Super Austenitic Steel | N08904 | 0.6-50mm | SWE / JPN / CHN |

| S31254 | 0.5-50mm | SWE / JPN / CHN | |

| N08926 | 0.5-50mm | SWE / JPN / CHN | |

| N08367 | 0.5-50mm | SWE / JPN / CHN | |

| Nickel Base Alloy | N08031 | 1.0-50mm | US / JPN / GER |

| N08810/N08800 | 0.8-50mm | US / JPN / CHN | |

| N08028 | 1.0-20mm | US / GER / JPN | |

| N08020 | 1.0-20mm | US / GER / JPN | |

| N08825 | 0.8-40mm | US / GER / SWE / JPN / CHN | |

| N10276 | 0.5-50mm | US / GER / JPN | |

| N06022 | 1.0-50mm | US / GER / JPN | |

| N06625 | 0.8-20mm | US / GER / CHN | |

| N04400 | 1.0-20mm | US / GER / JPN | |

| N06600 | 1.0-50mm | US / GER / JPN / CHN | |

| N02201 | 0.5-20mm | US / JPN | |

| Titanium | TA1/Gr1 | 0.5-50mm | JPN / CHN |

| TA2/Gr2 | 0.5-50mm | JPN / CHN | |

| Welding Material | ERNiCrMo-13 | 1.2、2.4mm | GER |

| ERNiCrMo-3 | 2.4mm | GER | |

| ERNiCrMo-4 | 2.4mm | US |

| Subsidiary | Main Equipments | Qty | Annual Capacity |

| Daxun Stainless steel co.(JiangSu) | Slitting Machine | 1 | Decorative coil:60,000 tons |

| Cutting Machine | 1 | ||

| No.4 And Hairline coil To coil Polishing Machine | 1 | ||

| No.4/Hairline Coil To Coil Polishing Machines | 1 | ||

| 8K/Super Mirror coil To coil Polishing Machines | 2 | ||

| 8K/Super Mirror Coil To Coil Polishing Machines | 3 | ||

| PVD Color Coating Machines | 4 | ||

| Liquid Chemical Coating Machines | 2 | ||

| Anti Finger Printing Machines | 2 | ||

| Auto Pick and Place machines | 16 | ||

| Plate Washing Machine | 1 | ||

| Daxun Stainless steel co.(Shanghai) | Cold Rolling Machine | 3 | 2B Coils:100,000 tons |

| Annealing & Pickling Line | 2 | Decorative Sheet;30,000 tons | |

| Slitting Machine | 1 | ||

| Cut to Length Machine | 1 | ||

| No.4/HL Polishing Machine(Sheet to Sheet) | 3 | ||

| 8K Polishing Machine(Sheet to Sheet) | 13 | ||

| PVD Titanium Coating Machine | 4 | ||

| Liquid Chemical Coating Machines | 1 | ||

| Daxun Stainless steel co.(Shandong) | Cold Rolling Machine | 3 | 2B & BA Coil:220,000 tons |

| Annealing & Pickling Line(2B & BA) | 2 | Decorative Sheet:60,000 tons | |

| Tension Levering & Skin Pass | 1 | ||

| Slitting Machine | 1 | ||

| Cut to Length Machine | 1 | ||

| No.4/HL Polishing Machine(Sheet to Sheet) | 1 | ||

| 8K Polishing Machine(Sheet to Sheet) | 11 | ||

| Automatic Copper Coating Machine | 1 | ||

| Digital Printing Machine | 1 | ||

| PVD Titanium Coating Machine | 3 | ||

| Liquid Chemical Coating Machines | 1 | ||

| Anti-finger Machine | 1 | ||

| Daxun Stainless steel co.(Sichuan) | Slitting Machine | 1 | 2B & BA Coil:180,000 tons |

| Cutting Machine | 1 | Decorative Sheet:50,000 tons | |

| No.4 And Hairline Sheet To Sheet Polishing Machine | 1 | ||

| No.4/Hairline Coil To Coil Polishing Machines | 1 | ||

| 8K/Super Mirror Sheet To Sheet Polishing Machines | 1 | ||

| 8K/Super Mirror Coil To Coil Polishing Machines | 1 | ||

| PVD Color Coating Machines | 1 | ||

| Liquid Chemical Coating Machines | 1 | ||

| Anti Finger Printing Machines | 1 |

SS 904L Surface Types of Stainless Steel Coils (6)

Information available for reference and download

Daxun is a trustworthy stainless steel coil manufacturer

As a professional manufacturer, Daxun ensures that all the products we produce are of high quality. Therefore, we ensure that all stainless steels are certified by ISO9001, SGS, CE, OQC and more international quality standards. We also conduct strict quality control to ensure that the stainless steel plates have less defects. At Daxun, you can rest assured that all products are durable, high quality and excellent in performance.

Recent hot case projects and products

Related Products (10)

Leading stainless steel coil Suppliers in China

Daxun has been engaged in international business for more than ten years. In 2023, its export revenue exceeded US$100 million, and its export volume ranked among the top Chinese stainless steel manufacturers. Daxun continues to improve its service skills. In order to serve the global market, we have established three export service facilities in China and cooperated with engineering enterprises, steel mills and international trading companies. Daxun provides stainless steel chain services and has established long-term cooperative relationships with dozens of well-known steel mills around the world. Its inventory includes 50,000 tons of conventional stainless steel coils and 20,000 tons of duplex steel, nickel-based alloys, heat-resistant steel and other metals. Daxun’s stainless steel materials are of consistent quality. Types, specifications and delivery weights strictly comply with standards.

What are 904L’s best qualities?

- This grade of stainless steel contains little carbon content. It is high in copper, which increases resistance to strong acids like sulphuric acid. The high concentration of nickel makes it resistant to stress corrosion cracking. It is also extremely resistant to crevice corrosion and stress corrosion cracking, which can affect other forms of steel. It can be employed in a variety of demanding conditions, including warm waters and chloride exposure. It’s suitable for both moderate and aggressive conditions.

- This type of stainless steel is extremely heat resistant, withstanding temperatures up to 400 degrees Celsius. It is heat treatable at temperatures ranging from 1090 to 1175 degrees Celsius, followed by quick cooling. This type of heat treatment is an excellent choice for hardening 904L steel.

- This type of steel is nonmagnetic due to its composition. It has great weldability, formability, and toughness in a variety of circumstances.

- 904L steel can be welded using any normal method, with no need for pre-heat or post-weld heat treatments.

What is 904L used for?

As mentioned earlier, 904L steel is the stainless steel used in the construction of Rolex watches. In industrial settings, it is valued for its high purity and its low sulfur content. A few of the places 904L is used includes:

- Seawater cooling devices.

- Wiring in electrostatic filtration devices.

- Oil refinery components.

- Gas scrubbing plant parts.

- Machinery for pulp and paper processing.

- Parts in machines used in sulfuric, acetic and phosphoric acid processing plants.

Fabrication Data

- Alloy 904L can be easily welded and processed by standard shop fabrication practices.

Cold Forming

- 904L is quite ductile and forms easily. The addition of molybdenum and nitrogen implies more powerful processing equipment may be necessary when compared with the standard 304/304L grades.

Hot Forming

- Hot working procedures require temperatures ranging from 1562 to 2102°F (850 -1150°C). Normally, hot working should be followed by a solution anneal and quench; however, for 904L, if hot forming is stopped at a temperature over 2012°F (1100°C) and the material is quenched immediately after, the material may be utilized without further heat treatment. It is critical that the entire workpiece be quenched from temperatures above 2012°F (1100°C). When partial heating or cooling falls below 2012°F (1100°C), or if cooling is too sluggish, hot working should always be followed by a solution anneal and quenching. 904L should be solution annealed at 1940-2084°F (1060-1140°C).

Machining

- The cold work hardening rate of Alloy 904L makes it less machinable than 410 and 304 stainless steels.

Welding

- Most conventional welding methods are compatible with Alloy 904L. Austenitic plate materials have a uniform austenitic structure and an equitable distribution of alloying elements. Certain elements, including as molybdenum, chromium, and nickel, are redistributed during solidification after welding. These segregations stay in the cast structure of the weld and can reduce corrosion resistance in certain situations. Segregation is less noticeable in 904L, which is typically welded with a filler metal of the same composition as the base metal but can also be welded without filler metal.

- The welding consumables for 904L are 20 25 CuL covered electrode and 20 25 CuL wire.

What are the applications that 904L stainless steel coils can be used?

Due to excellent corrosion resistance, quality grade 904L stainless steel coils are widely used for below applications.

- Petrochemical equipment, reactor

- Heat exchanger

- Power plant flue gas desulfurization device

- Organic acid treatment system

- Sea water heat exchanger

- Paper industry equipment

- Pharmaceutical industry and other chemical equipment

- Pressure vessel

- Food equipment

What are the commonly used surfaces of stainless steel coils?

The surface finish of 201 stainless steel coil might vary depending on the cold rolling processing methods used and the surface treatment used after rolling. Surface treatments for stainless steel coils include NO.1, 2B, 4, HL, 6, 8, BA, TR hard, heavy rolling bright 2H, polished bright, and other surface treatments:

- NO.1: The surface obtained after hot rolling, heat treatment and pickling of stainless steel strip. It is used to remove the black oxide scale formed by pickling or similar processes during hot rolling and heat treatment. It ranks first in surface treatment. The No. 1 surface is silvery white and matte. It is generally used in heat-resistant and corrosion-resistant industries that do not require high surface gloss, such as the alcohol industry, chemical industry, large containers, etc.

- 2B: Unlike the 2D surface, the 2B surface is smoothed by a light roller, and the surface is brighter. The surface roughness Ra value measured by the equipment ranges from 0.1 to 0.5μm, which is a typical value for most processing types. This stainless steel strip surface has the strongest adaptability and is suitable for industries such as chemical, papermaking, petroleum, medical, and a wide range of fields such as building curtain walls.

- TR hard surface: TR stainless steel is also called hard steel. Its characteristic steel grades include 304 and 301, which are used for items that require high strength and hardness, such as railway vehicles, conveyor belts, springs and washers. The idea is to use the work hardening characteristics of austenitic stainless steel to improve the strength and hardness of steel plates through cold working methods such as rolling. In order to replace the gentle flatness of the 2B base surface, the hard material is gently rolled by a few percent to tens of percent, and no annealing is performed after rolling. Therefore, the TR hard surface of the hard material is the rolled surface after the cold rolling process.

- Re-rolled bright 2H: After the rolling operation, the stainless steel strip will be bright annealed. A continuous annealing line can be used to quickly cool the strip. The stainless steel strip travels along the line at a speed of 60-80m/min. After this process, the surface finish will be 2H re-rolled bright.

- No. 4: The No. 4 surface has a good polishing effect and is brighter than No. 3. It can also be obtained by polishing the cold-rolled stainless steel plate with a 2D or 2B surface, and then polishing the processed surface with a sanding belt with a particle size of 150-180#. The tool measures the surface roughness (Ra) between 0.2 and 1.5μm. The No. 4 surface is widely used in restaurants and cooking equipment, medical equipment, architectural decoration, containers and other applications.

- HL: The HL surface is often called a hairline finish. The Japanese JIS standard specifies a continuous hairline abrasive surface obtained by polishing with a 150-240# abrasive belt. The restrictions under the Chinese GB3280 standard are unclear. HL surface finish is commonly used for architectural decoration, such as elevators, escalators, and exterior walls.

- No. 6: The No. 6 surface is further polished on the basis of No. 4 with a Tampico brush or a W63 grit abrasive material specified in the GB2477 standard. The surface has good metallic luster, softness, weak reflection, and no imaging. Due to its good performance, it is very suitable for curtain walls, tassel decoration, and cooking supplies.

- BA: BA is a surface that is brightly heat treated after cold rolling. Bright heat treatment is annealing in a protective atmosphere to ensure that the surface is not oxidized and retain the gloss of the cold-rolled surface, and then it is polished with a high-precision smooth roller to improve the surface brightness. The instrument evaluates the surface roughness to be 0.05-0.1μm, indicating that the surface is close to a mirror surface. BA surfaces can be used in a variety of applications, including food utensils, household appliances, medical equipment, automotive parts, and decorations.

- No. 8: Mirror surface, maximum reflectivity, no abrasive particles. The stainless steel deep processing industry also refers to 8K board. BA material is often used as raw material for mirror processing. It only needs to be polished. The surface is beautiful after mirror processing and is often used in building entrances and interior decoration.

What is the standard sea packaging of 201 stainless steel coil?

- Standard export sea packaging:

Waterproof Paper Winding+PVC Film+Strap Banding+Wooden Pallet or Wooden Case; - Customized packaging as your request (Logo or other contents accepted to be printed on the packaging);

- Other special packaging will be designed as customer’s request;

Eye to wall and eye to sky are both available; - By International Express: DHL/UPS/FEDEX/EMS and our own express line;

- By air, sea or land;

- Shipping Port: Shanghai, Ningbo, Qingdao, Tianjin or as your request.

Contact your stainless steel coil suppliers

- You can easily order stainless steel coils in any size and quantity online.

Alternatively, our friendly sales team will be happy to take your order. Simply call +86 13382898899 or email Daxunhejin@gmail and we will get back to you as soon as possible.

Please fill in the form on the “Contact Us” page, or call our sales manager at “+86 13382898899”, we will contact you as soon as possible. Our WhatsApp is online, and email (Daxunalloy@gmail.com) will be checked within 6 hours. Every inquiry or message will be responded to promptly. In addition, we share market information with our customers every week

Samples can be provided free of charge, but the freight is borne by the customer, and will be refunded after cooperation.

We’ve exported to more than 42 countries, such as Canada, Chile, Kuwait, Germany, South Korea, Saudi Arabia, Singapore etc.

Our MOQ is 1 ton for stainless steel sheet.

We have a complete organization from raw material purchasing to processing and shipment arranging. In the whole chain, the documentary people ad QC will look for and check it by precise requirements.The third party inspection is welcomed.

Trial orders can be delivered within a week. For regular orders, it takes two weeks roughly.