Daxun is a professional supplier of duplex 2507 stainless steel coils

Являясь ведущим поставщиком и экспортером рулонной нержавеющей стали в Китае, компания Daxun поставляет рулонную нержавеющую сталь по всему миру.

- Марка рулона: SS 2507-S32750

- Чрезвычайная устойчивость к равномерной коррозии

- Хорошая устойчивость к неорганическим кислотам/хлоридам

- Работает с разбавленной соляной кислотой.

- Улучшенная обрабатываемость и свариваемость

- Высокая ударная вязкость

Мировой лидер в сфере услуг по изготовлению рулонов нержавеющей стали

Daxun — это поставщик рулонов дуплексной стали 2507 с полным спектром услуг в Китае, предлагающий рулоны толщиной от 0,5 мм до 3,16 мм. Листовая дуплексная сталь 2507 — это менее дорогой сплав, чем 904L или 6% молибденовая супераустенитная нержавеющая сталь. Сплав 2507 (UNS S32750) — это супердуплексная нержавеющая сталь с 25% хрома, 4% молибдена и 7% никеля. Он предназначен для сложных применений, требующих высокой прочности и коррозионной стойкости, таких как химическая обработка, нефтехимическое оборудование и оборудование для морской воды. Сталь очень устойчива к хлоридному коррозионному растрескиванию под напряжением, имеет высокую теплопроводность и низкий коэффициент теплового расширения. Высокая концентрация хрома, молибдена и азота обеспечивает хорошую стойкость к точечной коррозии, щелевой коррозии и общей коррозии.

Dah Hsun — сертифицированная по стандарту ISO 9001:2008 фирма, которая является крупным поставщиком и экспортером рулонов нержавеющей стали ASTM A240. Рулоны нержавеющей стали могут быть разрезаны по вашим требованиям и включают полный набор результатов заводских испытаний. Доступны индивидуальные длины и ширины до 2000 мм. Экспорт — наша специализация! Мы можем получить несколько труднодоступных марок и/или нестандартных размеров, чтобы удовлетворить особые потребности наших клиентов. У нас большой опыт обработки рулонной стали, и мы можем разделить все рулоны нержавеющей стали на нужные размеры. Представляем нашу обширную линейку товаров из нержавеющей стали Dah Hsun — вершину надежности, долговечности и производительности. Мы рады предоставить широкий выбор марок и разновидностей для удовлетворения разнообразных потребностей промышленных и архитектурных приложений.

Наши рулоны из нержавеющей стали, которые варьируются от аустенитной серии до ферритной серии и других специальных категорий, хорошо известны своей высокой производительностью и обширными требованиями. Аустенитная серия включает 304/304L/304J1, 321 и 316/316L/317L/316Ti/310/309, которые могут соответствовать различным требованиям к толщине и обеспечивать различные виды обработки поверхности, включая 2B, BA, NO.4, 8K, SB, HL, NO.1 и т. д.

Наша линейка ферритов, включающая 430, сверхчистый феррит 443 и 436L/439/444/441, предназначена для клиентов, ищущих уникальные качества и области применения. Эти материалы могут иметь толщину от 0,4 мм до 3,0 мм и предлагают различные варианты обработки поверхности, такие как 2B, BA, NO.4, 8K, SB, HL и т. д.

Выбирая наши змеевики из нержавеющей стали, вы инвестируете в материал, который обеспечивает длительный срок службы, большую надежность и исключительную производительность. Не идите на компромисс в отношении качества; выбирайте наши решения из нержавеющей стали и посмотрите, какое влияние они могут оказать на ваш проект. Свяжитесь с Daxun сегодня для получения дополнительной информации или для размещения заказа на змеевик из нержавеющей стали в требуемых вам характеристиках и количествах.

Данные

- Параметр

- Элемент

- Механические свойства

- ФИЗИЧЕСКИЕ СВОЙСТВА

- Все эквивалентно

- 2507 Рулонный запас

| Процесс производства рулонов нержавеющей стали 2507/S32750 | Горячекатаный (HR) / Холоднокатаный (CR) |

| Марки рулонной нержавеющей стали 2507/S32750 | 201 / 304 / 304L / 2507/S32750 / 309S / 420 / 316 / 316L / 316Ti / 317L / 321 / 321H / 347 / 347H / 904L и т. д. |

| Номер UNS – UNS S2507/S32750, UNS S31008, UNS S31600, UNS S31603, UNS S31603, UNS S31600, UNS S31703, UNS S32100, UNS S34700, UNS S34709, UNS S8904 | |

| EN № 1.4845, 1.4401, 1.4404, 1.4571, 1.4438, 1.4541, 1.4550, 1.4551, 1.4539 | |

| Толщина рулона нержавеющей стали 2507/S32750 | ТОЛЩИНА ОТ 0,6 ММ ДО 16 ММ |

| Ширина рулона нержавеющей стали 2507/S32750 | 1250 мм / 1500 мм / 2000 мм / 04 фута / 05 футов и индивидуальная ширина резки по требованию |

| Длина рулона нержавеющей стали 2507/S32750 | 2400 мм / 2420 мм / 6000 мм / 08 футов / 10 футов / Длина рулона и индивидуальная длина по требованию |

| Поверхностная отделка рулона нержавеющей стали 2507/S32750 | 2B, 2D, BA, МАТОВЫЙ, МАТОВЫЙ ПВХ, № 4, № 5, SB, HR, № 8, Зеркальный, Волосяной, Кисть, Текстурированный, Масляная основа, Мокрая полировка, Полировка с обеих сторон. |

| Покрытие рулонов нержавеющей стали 2507/S32750 | ПВХ-покрытие Обычное / Лазерное, Пленка: 100 микрометров, Цвет: черный/белый. |

| 2507/S32750 Рулон нержавеющей стали Другие испытания | NACE MR0175, ультразвуковой тест, тест IGC, испытание на межкристаллитную коррозию согласно ASTM A262 Practice E, испытание на удар по Шарпи, макроопределение, размер зерна, твердость и т. д. |

| 2507/S32750 Рулон нержавеющей сталиУслуги с добавленной стоимостью | Газовая резка / плазменная резка с ЧПУ / профилирование / прокатка / гибка / изготовление листового металла / сверление / перфорация / механическая обработка / пескоструйная обработка / дробеструйная обработка / термообработка |

| Упаковка рулонов нержавеющей стали 2507/S32750 | Насыпью / Каррата / Деревянный поддон / Деревянный ящик-a / Пластиковые тканевые обертки |

| Отгрузка и транспортировка рулонов нержавеющей стали 2507/S32750 | По дороге – Грузовик / Поезд Частичная загрузка, Полная загрузка, По морю – Конвенциональное судно для перевозки генеральных грузов / FCL (Полная загрузка контейнера) / LCL (Меньшая загрузка контейнера) / 20-футовый контейнер / 40-футовый контейнер / 45-футовый контейнер / Контейнер High Cube / Контейнер с открытым верхом, По воздуху – Грузовые гражданские пассажирские и грузовые самолеты |

| Сертификат испытаний рулонного материала из нержавеющей стали 2507/S32750 | Сертификат испытаний производителя согласно EN10204 3.1, 3.2 / Сертификат лабораторных испытаний от лаборатории, одобренной NABL. / Под сторонним инспекционным агентством, таким как SGS, TUV, DNV, LLOYDS, ABS, Бюро индийских стандартов, одобрено BIS и т. д. |

| Производитель | POSCO, Aperam, Jindal Stainless, DKC Korea, Thyssenkrup, Baosteel, TISCO, Arcelor Mittal, VDM, Nippon Metal, Outokumpu, Qingshan, Delong. |

| Порт отправки | Шанхай/Порт Нинбо/Тяньцзинь/Циндао |

| Оценка | Супер Дуплекс 2507 |

| Обозначение UNS | S32750 |

| Углерод (C) Макс. | 0,03 |

| Марганец (Mn) Макс. | 1.2 |

| Фосфор (P) Макс. | 0,035 |

| Сера (S) Макс. | 0,02 |

| Кремний (Si) Макс. | 0,8 |

| Хром (Cr) | 24,0–26,0 |

| Никель (Ni) | 6,0–8,0 |

| Молибден (Mo) | 3,0–5,0 |

| Азот (N) | 0,24–0,32 |

| Железо (Fe) | Бал. |

| Медь (Cu) | 0,5 |

| Другие элементы | — |

| Физические свойства супердуплексных сплавов 2507 в отожженном состоянии при температуре от -20°F до +100°F | ||||||||||||||

| Предел прочности | Предел текучести | |||||||||||||

| Сплав | Обозначение UNS | Спец. | пси | МПа | кси | пси | МПа | кси | Удлинение в 2 дюйма (мин.) % | Требуемый размер зерна | Макс. твердость | Модуль упругости (x106 фунтов на кв. дюйм) | Средний коэффициент теплового расширения (дюйм./дюйм./°F x 10-6) | Теплопроводность (БТЕ-дюйм/ фут2-ч-°F) |

| Супер Дуплекс 2507 | S32950 | А789, А790 | 100,000 | 690 | 100 | 70,000 | 485 | 70 | 20 | — | 30,5 Рс | — | — | — |

| Супер Дуплекс 2507 | S32750 | А789, А790 | 116,000 | 800 | 116 | 80,000 | 550 | 80 | 15 | — | 32 Рс | 27.5 | 7.2 | 98 |

| Плотность, фунт/дюйм3 | 0,28 |

| Модуль упругости, фунт/кв. дюйм | 29.0x 106 |

| Коэффициент теплового расширения, 68-212˚F, /˚F | 7,5 х 10-6 |

| Теплопроводность, БТЕ/фут·ч·˚F | 8 |

| Удельная теплоемкость, БТЕ/фунт ˚F | 0,12 |

| Удельное электрическое сопротивление, мкОм-дюйм | 31,5 |

| Ассортимент продукции Super Duplex 2507 | |||

| Сплав | Обозначение UNS | Веркстофф NR. | Технические характеристики* |

| Супер Дуплекс 2507 | S32750 | 1.441 | А/СА789, А/СА790 |

| • Змеевик Tisco из нержавеющей стали 2507 | • Профильная катушка BQ из нержавеющей стали 2507 |

| • SS 2507 Перфорированная катушка | • Самая продаваемая катушка из нержавеющей стали 2507 размером 4×8 футов с зеркальной полировкой |

| • Катушка из нержавеющей стали 2507 UNS S31635 | • Декоративная полоса из нержавеющей стали, холоднокатаная, рулон ss 2507 |

| • Катушка 240 с рифленой проволокой 2507 | • Отделка линии волос SS 2507 катушка |

| • Катушка из нержавеющей стали Aperam 2507 | • Лазерная резка рулона ss 2507 |

| • Катушка из нержавеющей стали 2507 | • Поставщик Tisco, рулон нержавеющей стали 2507 толщиной 3 мм |

| • Катушка 240 2507 | • Декоративная катушка из нержавеющей стали 2507 |

| • SS 2507 Рельефная катушка | • Катушка Scotch Brite SS 2507 |

| • Катушка Outokumpu SS 2507 | • Рулон из нержавеющей стали Baosteel 2507 |

| • SA 240 2507 нержавеющая стальная катушка | • Катушка из нержавеющей стали 2507 |

| • Яркий кованый узор, декоративная катушка из нержавеющей стали SS 2507 | • Черная спираль SS 2507 толщиной 4 мм |

| • Катушка из нержавеющей стали 2507 | • Катушка из ярко-травленой нержавеющей стали 2507 |

| • Катушка из нержавеющей стали DIN 1.4571 | • Холоднокатаная, термообработанная рулонная сталь 2507 |

| • Катушка из нержавеющей стали ThyssenKrupp 2507 | • Холоднокатаная рулонная сталь AISI SS 2507 толщиной 3 мм |

| • Рулон нержавеющей стали ASTM A240 2507 | • Поставка мельницы, катушка SS 2507 |

| • Полировка поверхности катушкой SS 2507 | • Катушка из стали SS 2507 класса Prime |

| • 2507 Нержавеющая сталь HR змеевик | • Катушка Carpenter Custom 450 из нержавеющей стали 2507 |

| • Рифленая катушка из нержавеющей стали 2507 | • Нарезанный по размеру рулон из нержавеющей стали 2507 |

| • Катушка с золотым лазерным узором из нержавеющей стали 2507 | • Немагнитная полировка катушки из нержавеющей стали 2507 |

| • Сверхтонкая зеркальная поверхность катушки BA ss 2507 | • Катушка ASME SA240 2507 |

| • Рулон из супераустенитной стали SS 2507 | • Пустая катушка из нержавеющей стали 2507 |

| • Катушка ASTM A240 2507 | • Перфорированная катушка из нержавеющей стали 2507 |

| • JMSS холоднокатаная рулонная сталь ss 2507 | • Рельефная катушка из нержавеющей стали 2507 |

| • Холоднокатаная рулонная сталь SS 2507 № 1 | • Дешевая холоднокатаная рулонная сталь ss 2507 по лучшей цене |

| • Катушка из нержавеющей стали SEW 400 2507 | • Прайс-лист на катушку из нержавеющей стали SS 2507 с отделкой щеткой |

| • Горячекатаная рулонная нержавеющая сталь 2507 | • Катушка SS URANUS B6 2507 |

| • Продвижение продаж катушки SS 2507 | • 2B SUS SS 2507 катушка |

| • Катушка из нержавеющей стали Cr 2507 | • Катушка из пищевой нержавеющей стали 2507 |

| • Сертификат заводских испытаний SS 2507 катушка | • № 4 катушки из нержавеющей стали SS 2507 с покрытием из ПВХ |

| • Катушка ASTM A240 2507 | • Рулон SS 2507, оловянно-золотисто-розовый |

| • Холоднокатаная, светлоотожженная рулонная сталь 2507 | • 2 мм катушка ASTM SS 2507 |

| • Шлифованная катушка из нержавеющей стали 2507 | • Гофрированная спираль из нержавеющей стали 2507 |

| • Популярная катушка AISI SS 2507 | • Катушка ASTM B625 2507 |

| • SS 2507 розово-золотистая катушка | • Матовая или матово-полированная катушка из нержавеющей стали 2507 |

| • Поверхностно-покрытый змеевик из нержавеющей стали 2507 | • Холоднокатаный, термообработанный, травленый рулон 2507 |

| • Сатинированная нержавеющая сталь 2507 катушка | • 10К зеркальная поверхность, катушка из нержавеющей стали SS 2507 |

| • Бронированная катушка из нержавеющей стали AISI 2507 | • Катушка из нержавеющей стали SS 2507 с золотым травлением |

| • Сатинированная нержавеющая сталь 2507 катушка | • Катушка SS 2507 калибра 18 |

| • Зеркальная отделка катушки SS 2507 | • Узорчатая спираль из нержавеющей стали 2507 |

| • SS 2507 катушка с отделкой Gold Brush | • Катушка из нержавеющей стали 2507 с отделкой №4 |

| • Катушка CR из нержавеющей стали 2507 | • Узорчатая спираль из нержавеющей стали 2507 |

| • Катушка из нержавеющей стали 2507 2B | • Кабина пассажирского лифта SS 2507 катушка |

Выбирайте Daxun и сделайте своих клиентов довольными.

Быстрый ответ 2507 Нержавеющая сталь катушка

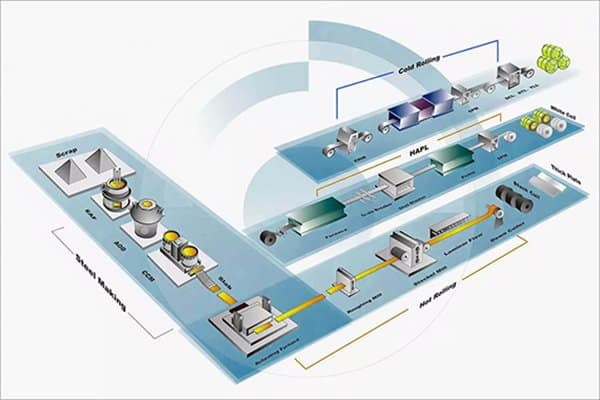

Мы обеспечиваем своевременную и быструю доставку изделий из нержавеющей стали для клиентов с срочными потребностями. За скоростью стоит системная поддержка от информационного потока до логистики и движения капитала. Например, с точки зрения информационного потока данные о заказах Daxun передаются в логистическую систему в режиме реального времени, и данные бесшовно связаны; с точки зрения логистики центр обработки находится недалеко от автомагистралей, рек и морей, с разумным планированием, быстрым реагированием, складскими и транспортными связями и эффективной загрузкой, что гарантирует выполнение задачи в срок. Материалы из нержавеющей стали Daxun имеют надежное качество, а их разновидности, спецификации и вес поставки строго соответствуют стандартам.

Преимущества Даксуна

Качество — это вера, а честность — это визитная карточка. Daxun стала пионером концепции «управления эффективностью» и внедрила модель управления «PDCA+Lean». Визитная карточка компании гласит: «Daxun = гарантированное качество». Daxun Stainless Steel достигает полной прослеживаемости каждой стальной пластины из системы ERP, включая ассортимент, спецификации и происхождение, а также выступает и поощряет борьбу с подделками в отрасли. Daxun Stainless Steel полагается на технологии для обработки и настройки, а высокая точность и высокое качество являются отраслевыми эталонами; с точки зрения обслуживания она продвигает управление жизненным циклом продукта, предоставляет профессиональные решения по выбору материалов и обработке перед продажей, строгий мониторинг во время продажи и предоставляет гарантии беспроблемного обслуживания после продажи.

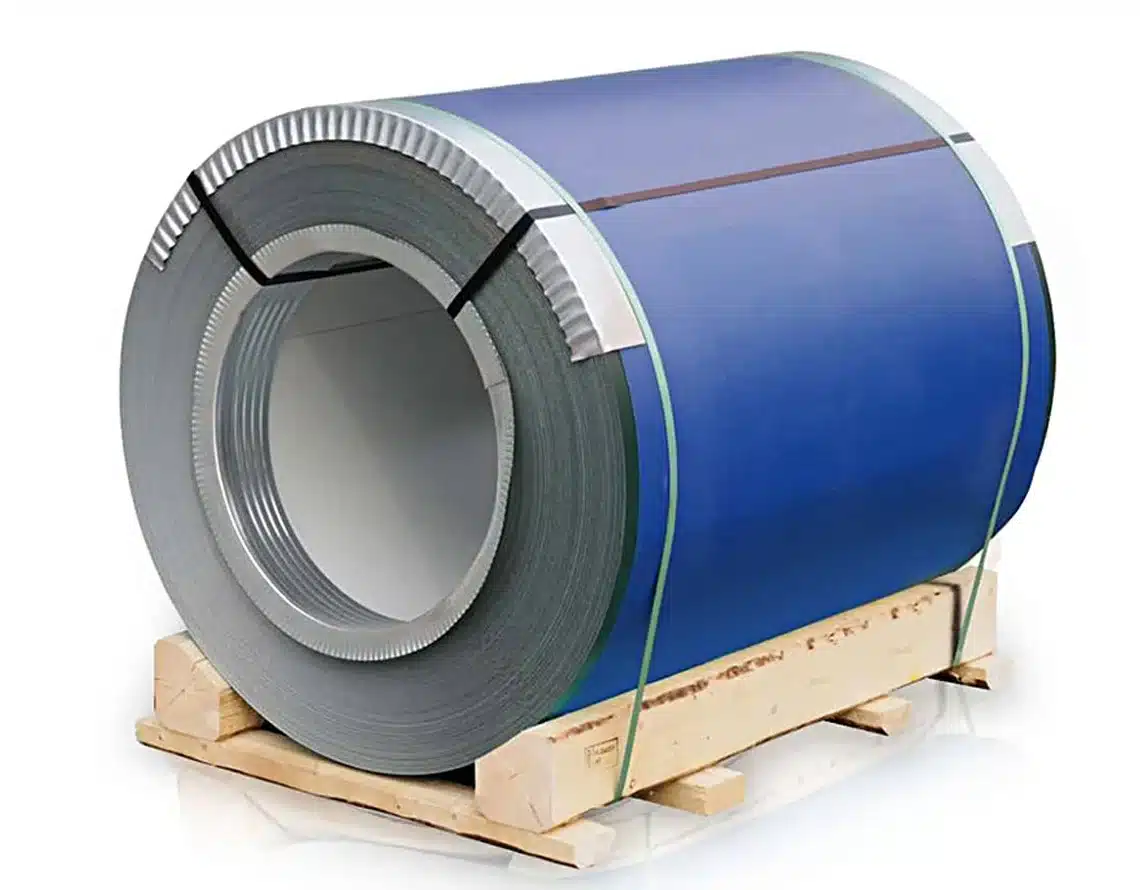

Упаковка рулона нержавеющей стали 2507

Daxun Alloy гарантирует наилучшее качество упаковки, поскольку она играет важную роль в международных грузоперевозках, где товары проходят через различные каналы, чтобы достичь конечного пункта назначения, поэтому мы уделяем особое внимание упаковке. Мы упаковываем наши товары разными способами в зависимости от продукта. Мы упаковываем наши продукты разными способами, такими как:

• Коробки и ящики

• Термоусадочная пленка

• Деревянные поддоны

• Деревянные ящики

Качество, доставка, проверка

- Daxun также проводит несколько испытаний на обеспечение качества. Эти испытания включают испытание на сплющивание, испытание на питтинг и сопротивление, механическое испытание, испытание на твердость, положительную идентификацию материала, испытание на расширение и т. д. Все эти испытания гарантируют, что материал подходит для требуемого применения.

- В процессе производства мы измеряем диаметр, толщину и поверхность изделия. Наш стандартный срок поставки составляет 7-15 дней, за исключением некоторых изделий специального размера, срок поставки увеличивается до 20 дней.

Срок поставки строго соответствует договору. - Поддержка сторонних агентств-клиентов при посещении завода для проведения инспекции

- Предоставляем бесплатные образцы клиентам для тестирования

- Поддержка инспекции завода на месте или видеоинспекции

Информация для заказа рулона нержавеющей стали 2507

Заказы на закупку должны включать количество, сорт, тип или категорию, ссылку API5L, толщину, ширину, длину и любые применимые приложения или дополнительные требования, связанные с химическим составом, механическими свойствами, термической обработкой, дополнительными испытаниями, производственным процессом, покрытием поверхности или конечной отделкой. Свяжитесь с Daxun сейчас, мы ответим на ваше письмо как можно скорее.

Техническая поддержка

Если вам нужна дополнительная техническая помощь, наш местный металлург и знающий персонал будут рады помочь. Кроме того, Daxun может похвастаться сертифицированной испытательной лабораторией — первой в отрасли многометаллического и пластикового инвентаря. Это, по нашему мнению, демонстрирует нашу непоколебимую преданность качеству и нашу философию как поставщика полного спектра услуг.

Характеристики рулона нержавеющей стали 2507

Daxun Alloy Позвольте вашему бренду быстро улучшиться

- Галерея

- Серия продуктов

- Основное оборудование

| Оценка | Тип | Толщина | Поверхность |

| аустенитный | 304/304H/304L/304J1 | 0,25-150 мм | 2Б/БА/№4/8К/СБ/ХЛ/№1 |

| 321 | 0,4-80 мм | 2Б/БА/№4/8К/СБ/ХЛ/№1 | |

| 316/316L/317L/316Ti | 0,3-80 мм | 2Б/БА/№4/8К/СБ/ХЛ/№1 | |

| Феррит | 430 | 0,4-3,0 мм | 2Б/БА/№4/8К/СБ/ХЛ |

| Сверхчистый феррит | 443 | 0,4-2,0 мм | 2Б |

| 436Л/439/444/441 | 0,5-3,0 мм | 2Б、2Д | |

| 409л | 0,4-2,5 мм | 2Б、2Д | |

| Супер аустенитная сталь | N08904 | 0,6-50 мм | Швеция / Япония / Китай |

| S31254 | 0,5-50 мм | Швеция / Япония / Китай | |

| N08926 | 0,5-50 мм | Швеция / Япония / Китай | |

| N08367 | 0,5-50 мм | Швеция / Япония / Китай | |

| Сплав на основе никеля | N08031 | 1,0-50 мм | США / Япония / Германия |

| N08810/N08800 | 0,8-50 мм | США / Япония / Китай | |

| N08028 | 1,0-20 мм | США / Германия / Япония | |

| N08020 | 1,0-20 мм | США / Германия / Япония | |

| N08825 | 0,8-40 мм | США / Германия / Швеция / Япония / Китай | |

| N10276 | 0,5-50 мм | США / Германия / Япония | |

| N06022 | 1,0-50 мм | США / Германия / Япония | |

| N06625 | 0,8-20 мм | США / Германия / Китай | |

| N04400 | 1,0-20 мм | США / Германия / Япония | |

| N06600 | 1,0-50 мм | США / Германия / Япония / Китай | |

| N02201 | 0,5-20 мм | США/Япония | |

| Титан | ТА1/Гр1 | 0,5-50 мм | Япония / Китай |

| ТА2/Гр2 | 0,5-50 мм | Япония / Китай | |

| Сварочный материал | ERNiCrMo-13 | 1.2、2.4мм | ГЕР |

| ЭРНиКрМо-3 | 2.4мм | ГЕР | |

| ЭРНиКрМо-4 | 2.4мм | НАС |

| Дочерняя компания | Основное оборудование | Кол-во | Годовая мощность |

| Компания Daxun из нержавеющей стали (Цзянсу) | Машина для продольной резки | 1 | Декоративный лист: 60 000 тонн |

| Машина для резки | 1 | ||

| № 4 и шлифовальная машина для листов с волосяным слоем | 1 | ||

| № 4/Машины для полировки катушек с волосяным стержнем | 1 | ||

| 8K/Super Mirror Лист к листу полировальные машины | 2 | ||

| 8K/Super Mirror Катушка к катушке полировальные машины | 3 | ||

| Машины для нанесения цветного покрытия методом PVD | 4 | ||

| Машины для нанесения жидких химических покрытий | 2 | ||

| Машины для защиты от отпечатков пальцев | 2 | ||

| Автоматические машины Pick and Place | 16 | ||

| Машина для мойки тарелок | 1 | ||

| Daxun Stainless Steel Co. (Шанхай) | Машина холодной прокатки | 3 | 2B Рулоны: 100 000 тонн |

| Линия отжига и травления | 2 | Декоративный лист;30 000 тонн | |

| Машина для продольной резки | 1 | ||

| Машина для резки по длине | 1 | ||

| № 4/HL Полировальный станок (лист к листу) | 3 | ||

| Полировальный станок 8K (лист к листу) | 13 | ||

| Машина для нанесения покрытия PVD титаном | 4 | ||

| Машины для нанесения жидких химических покрытий | 1 | ||

| Daxun Stainless Steel Co. (Шаньдун) | Машина холодной прокатки | 3 | Рулон 2B и BA: 220 000 тонн |

| Линия отжига и травления (2B и BA) | 2 | Декоративный лист: 60 000 тонн | |

| Снятие натяжения и проход кожи | 1 | ||

| Машина для продольной резки | 1 | ||

| Машина для резки по длине | 1 | ||

| № 4/HL Полировальный станок (лист к листу) | 1 | ||

| Полировальный станок 8K (лист к листу) | 11 | ||

| Автоматическая машина для нанесения медного покрытия | 1 | ||

| Цифровая печатная машина | 1 | ||

| Машина для нанесения покрытия PVD титаном | 3 | ||

| Машины для нанесения жидких химических покрытий | 1 | ||

| Машина против пальцев | 1 | ||

| Daxun Stainless steel co.(Сычуань) | Машина для продольной резки | 1 | 2B и BA Рулон: 180 000 тонн |

| Машина для резки | 1 | Декоративный лист: 50 000 тонн | |

| № 4 и шлифовальная машина для листов с волосяным слоем | 1 | ||

| № 4/Машины для полировки катушек с волосяным стержнем | 1 | ||

| 8K/Super Mirror Лист к листу полировальные машины | 1 | ||

| 8K/Super Mirror Катушка к катушке полировальные машины | 1 | ||

| Машины для нанесения цветного покрытия методом PVD | 1 | ||

| Машины для нанесения жидких химических покрытий | 1 | ||

| Машины для защиты от отпечатков пальцев | 1 |

SS 2507 Типы поверхности рулонов нержавеющей стали (6)

Информация доступна для ознакомления и скачивания

Daxun — надежный производитель рулонов нержавеющей стали.

Как профессиональный производитель, Daxun гарантирует, что вся производимая нами продукция отличается высоким качеством. Поэтому мы гарантируем, что все виды нержавеющей стали сертифицированы по стандартам ISO9001, SGS, CE, OQC

Последние горячие проекты и продукты

Related Products (10)

Ведущие поставщики рулонной нержавеющей стали в Китае

Daxun занимается международным бизнесом более десяти лет. В 2023 году его экспортная выручка превысила 100 миллионов долларов США, а объем экспорта вошел в число ведущих китайских производителей нержавеющей стали. Daxun продолжает совершенствовать свои навыки обслуживания. Чтобы обслуживать мировой рынок, мы создали три экспортных сервисных центра в Китае и сотрудничаем с инжиниринговыми предприятиями, сталелитейными заводами и международными торговыми компаниями. Daxun предоставляет услуги по изготовлению цепей из нержавеющей стали и установила долгосрочные отношения сотрудничества с десятками известных сталелитейных заводов по всему миру. Его запасы включают 50 000 тонн обычных рулонов нержавеющей стали и 20 000 тонн дуплексной стали, сплавов на основе никеля, жаропрочной стали и других металлов. Материалы из нержавеющей стали Daxun отличаются стабильным качеством. Типы, спецификации и вес поставки строго соответствуют стандартам.

Что такое нержавеющая сталь Duplex 2507?

Нержавеющая сталь Duplex 2507 — это супердуплексная сталь с низким содержанием углерода (до 0,03%), хрома (~25%), никеля (~7%) и молибдена (~4%). Нержавеющая сталь Duplex 2507 разработана для удовлетворения высоких требований применений, требующих высокой прочности и коррозионной стойкости. К таким применениям относятся химическое технологическое оборудование, нефтехимическая промышленность и оборудование для морской воды. Эта сталь очень устойчива к коррозионному растрескиванию под напряжением, вызванному хлоридами. Благодаря высокому содержанию хрома, молибдена и азота она обеспечивает отличную стойкость к точечной коррозии, щелевой коррозии и общей коррозии.

Как изготавливается нержавеющая сталь Duplex 2507?

- Нержавеющая сталь Duplex 2507 обычно производится тем же способом, что и другие современные высоколегированные стали. Электродуговая печь используется для плавки стального лома и добавления желаемых сплавов. После расплавления сталь перемещается в конвертер AOD (аргонно-кислородное обезуглероживание), где происходит множество важных процессов, включая обезуглероживание, очистку от серы и устранение растворенных газов.

- Азот обычно добавляется в сталь в процессе AOD. Затем сталь отправляется в ковшовую печь, где происходит корректировка включений.

- После этих предварительных процедур расплавленная сталь переносится на операцию литья, которая может производить отдельные слитки (огромные металлические блоки) или непрерывно производимые блюмы. Эти твердые стальные блюмы или слитки дополнительно очищаются путем повторного нагрева, а затем куются или прокатываются до желаемой толщины. Для достижения однородной внутренней структуры используется термическая обработка, известная как отжиг на твердый раствор, с последующей процедурой закалки в воде.

- Материалы для рулонов Duplex 2507 могут быть изготовлены с использованием процессов горячей или холодной формовки. Для горячей формовки температура должна быть установлена в диапазоне от 1024 °C до 1232 °C. После этапа горячей формовки следует выполнить процесс отжига на твердый раствор при минимальной температуре 1052-1125 °C с последующей быстрой закалкой в воде. Холодная формовка, которая включает гибку, глубокую вытяжку, экструзию и прессование, требует последующей термической обработки, которая включает отжиг на твердый раствор и закалку.

Чем нержавеющая сталь Duplex 2507 отличается от дуплексной стали?

- Нержавеющая сталь Duplex 2507 считается супердуплексной нержавеющей сталью. Дуплексные нержавеющие стали — это тип нержавеющей стали, микроструктура которой содержит как феррит, так и аустенит примерно в равных количествах. Они объединяют некоторые из наиболее ценных особенностей каждой из этих фаз. Эта уникальная смесь обеспечивает дуплексной нержавеющей стали высокую коррозионную стойкость, а также высокую механическую прочность. Однако разные марки дуплексной стали обеспечивают разные уровни коррозионной стойкости. Хотя они обладают хорошей стойкостью к локальной коррозии, включая точечную коррозию, щелевую коррозию и коррозионное растрескивание под напряжением, точный уровень стойкости варьируется в зависимости от марки и состава сплава. Дуплексные нержавеющие стали делятся на четыре категории в зависимости от их диапазона PREN (эквивалентного числа стойкости к точечной коррозии). Среди этих групп супердуплексная нержавеющая сталь имеет число PREN в диапазоне от 38 до 45.

Каковы области применения нержавеющей стали Duplex 2507?

Некоторые распространенные области применения нержавеющей стали Duplex 2507 включают:

- Опреснение.

- Оборудование для нефтегазовой отрасли, включая морские платформы, трубопроводы и обсадные трубы скважин.

- Оборудование для химической обработки, особенно для работы с едкими химикатами.

- Целлюлозно-бумажная промышленность, в частности оборудование для отбеливания.

- Применение в нефтехимической промышленности, включая удаление ПВХ.

- Установки опреснения воды.

- Оборудование для энергетической промышленности, такое как системы десульфурации дымовых газов (ДДГ).

- Морские компоненты, включая гребные винты и валы.

- Оборудование для контроля загрязнения, такое как скрубберы.

- Фитинги являются важнейшими компонентами для соединения и управления потоком жидкостей в трубопроводах и системах. Сюда входят колена, тройники, заглушки, возвраты, заглушки, крестовины, редукторы и ниппели труб и т. д.

Каковы преимущества использования нержавеющей стали Duplex 2507?

Преимущества использования нержавеющей стали Duplex 2507 включают в себя:

- Он очень устойчив к точечной коррозии, имея PREN до 43. Это означает, что он имеет лучшую коррозионную стойкость, чем такие марки нержавеющей стали, как 254SMO. Duplex 2507 также обладает высокой стойкостью к другим типам коррозии, таким как коррозионное растрескивание под напряжением (SCC), щелевая коррозия и общая коррозия. Эти объединенные коррозионно-стойкие качества делают Duplex 2507 адаптивной и надежной альтернативой для широкого спектра применений в суровых условиях.

- 2507 обеспечивает вдвое больший предел текучести, чем нержавеющая сталь класса 300. Это преимущество в прочности позволяет использовать более тонкие стальные секции и снижать материальные затраты для оборудования, работающего при тех же уровнях нагрузки.

- Она имеет вдвое большую текучесть и прочность на разрыв, чем стандартная нержавеющая сталь. Это приводит к значительно лучшей износостойкости.

Стандарты

- АСТМ/АСМЕ ………. A240 – UNS S32750

ЕВРОНОРМ………… 1.4410 – X2 Cr Ni MoN 25.7.4

AFNOR……………….. Z3 CN 25.06 Az

КОРРОЗИОННАЯ УСТОЙЧИВОСТЬ

Общая коррозия

- SAF 2507™ обладает высокой устойчивостью к коррозии, вызываемой органическими кислотами, например, менее 0,05 мм/год в 10% муравьиной и 50% уксусной кислоте, тогда как у ASTM 316L скорость коррозии превышает 0,2 мм/год. Чистая муравьиная кислота, см. рисунок 4. Также в загрязненной кислоте SAF 2507™ остается устойчивым.

- На рисунках 5 и 6 показаны результаты испытаний SAF™ 2507 и различных нержавеющих сталей и никелевых сплавов в уксусной кислоте, загрязненной хлоридами, которые на практике часто присутствуют в технологических процессах.

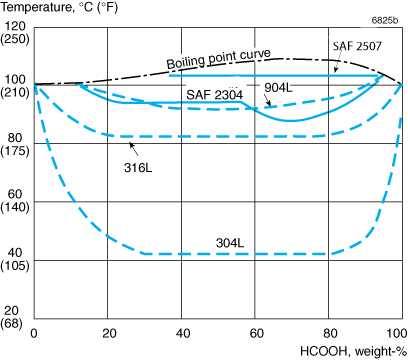

Рисунок 4. Диаграмма изокоррозии в муравьиной кислоте. Кривые представляют скорость коррозии 0,1 мм/год (4 мпг) в застойном тестовом растворе.

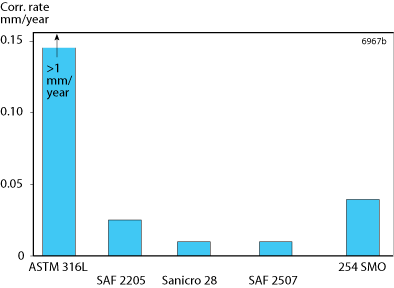

Рисунок 5. Скорость коррозии различных сплавов в 80% уксусной кислоте с 2000 ppm хлорид-ионов при 90°C.

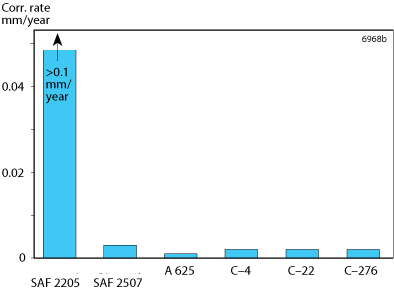

Рисунок 6. Скорость коррозии различных сплавов в концентрированной уксусной кислоте с 200 ppm хлорид-ионов.

Практический опыт использования SAF™ 2507 в органических кислотах, например, на заводах по производству терефталевой кислоты, показал, что этот сплав обладает высокой устойчивостью к этому типу среды. Таким образом, сплав является конкурентоспособной альтернативой высоколегированным аустенитам и никелевым сплавам в приложениях, где стандартные аустенитные нержавеющие стали подвергаются коррозии с высокой скоростью.

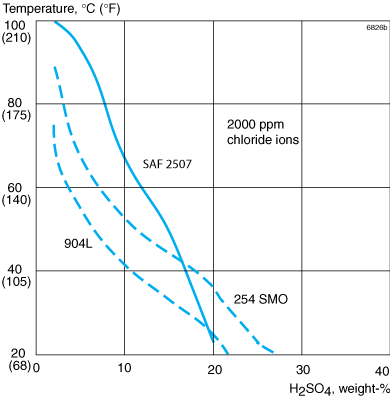

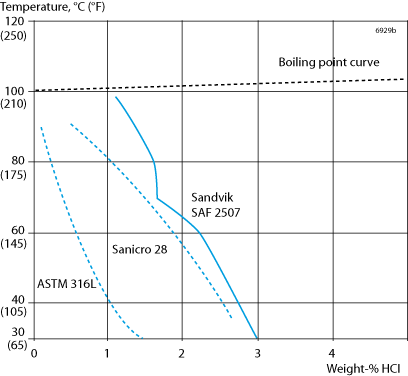

Стойкость к неорганическим кислотам сопоставима или даже превосходит стойкость высоколегированных аустенитных нержавеющих сталей в определенных диапазонах концентраций. На рисунках 7–9 показаны изокоррозионные диаграммы для серной кислоты, серной кислоты, загрязненной 2000 ppm хлорид-ионов, и соляной кислоты соответственно.

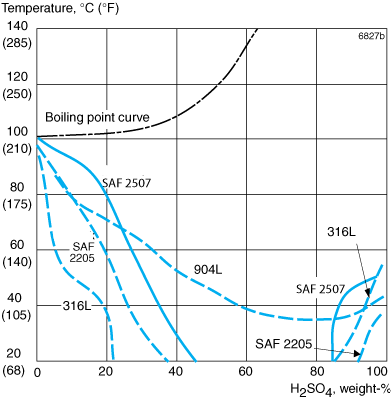

Рисунок 7. Диаграмма изокоррозии в естественно аэрированной серной кислоте. Кривые представляют скорость коррозии 0,1 мм/год (4 мпг) в застойном тестовом растворе.

Рисунок 8. Диаграмма изокоррозии, 0,1 мм/год (4 мпг) в естественно аэрированной серной кислоте, содержащей 2000 ppm хлорид-ионов.

Рисунок 9. Диаграмма изокоррозии в соляной кислоте. Кривые представляют скорость коррозии 0,1 мм/год (4 мпг) в застойном тестовом растворе.

Питтинговая и щелевая коррозия

Стойкость нержавеющей стали к точечной и щелевой коррозии определяется в первую очередь содержанием хрома, молибдена и азота. Производственные и производственные методы, например, сварка, также имеют важное значение для фактической производительности в эксплуатации.

Параметром для сравнения стойкости к точечной коррозии в хлоридной среде является число PRE (эквивалент стойкости к точечной коррозии).

PRE определяется как, в весовых процентах

PRE = %Cr + 3,3 x %Mo + 16 x %N

Для дуплексных нержавеющих сталей стойкость к точечной коррозии зависит от значения PRE как в ферритной фазе, так и в аустенитной фазе, так что фаза с самым низким значением PRE будет ограничивать фактическую стойкость к точечной коррозии. В SAF™ 2507 значение PRE одинаково в обеих фазах, что достигается за счет тщательного баланса элементов.

Минимальное значение PRE для бесшовных труб SAF™ 2507 составляет 42,5. Это значительно выше, чем, например, значения PRE для других дуплексных нержавеющих сталей типа 25Cr, которые не являются супердуплексными. Например, UNS S31260 25Cr3Mo0.2N имеет минимальное значение PRE 33.

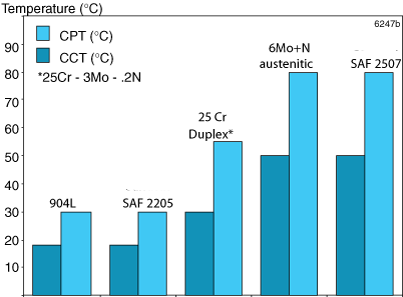

Одним из самых жестких испытаний на точечную и щелевую коррозию, применяемых к нержавеющей стали, является ASTM G48, т. е. воздействие 6% FeCl 3 с трещинами и без них (методы A и B соответственно). В модифицированной версии испытания ASTM G48 A образец подвергается воздействию в течение 24 часов. При обнаружении точечных дефектов вместе со значительной потерей веса (>5 мг) испытание прерывается. В противном случае температуру повышают на 5 °C (9 °F) и испытание продолжают с тем же образцом. На рисунке 11 показаны критические температуры точечного и щелевого дефектов (CPT и CCT) по результатам испытания.

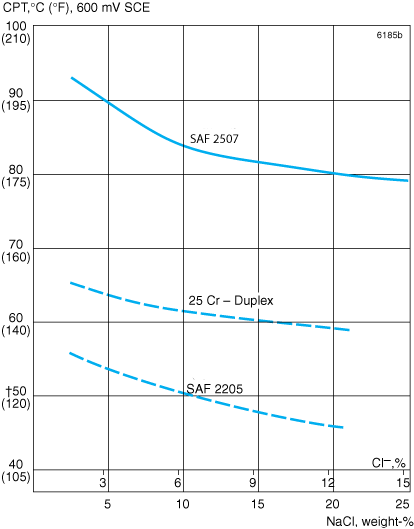

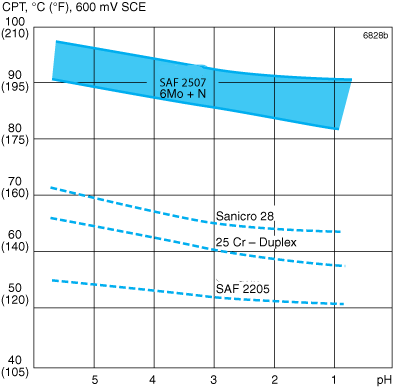

Потенциостатические испытания в растворах с различным содержанием хлорида представлены на рисунке 11. Рисунок 12 показывает влияние повышенной кислотности. В обоих случаях приложенный потенциал составляет 600 мВ против SCE, что является очень высоким значением по сравнению с тем, которое обычно ассоциируется с естественной нехлорированной морской водой, что приводит к более низким критическим температурам по сравнению с большинством практических условий эксплуатации.

Рисунок 10. Критические температуры образования питтингов и трещин в 6% FeCl 3 , 24 ч (аналогично ASTM G48).

Полоса рассеяния для SAF™ 2507 и 6Mo+N иллюстрирует тот факт, что оба сплава имеют одинаковую стойкость к точечной коррозии, а значения CPT находятся в диапазоне, показанном на рисунке.

Испытания проводились в естественной морской воде для определения критической температуры щелевой коррозии образцов с приложенным потенциалом 150 мВ против SCE. Температура повышалась на 4°C (7 o F) каждые 24 часа до тех пор, пока не возникала щелевая коррозия. Результаты показаны в таблице ниже.

| Сплав | ЦКТ (°С) |

|---|---|

| САФ 2507 | 64 |

| 6Мо+N | 61 |

В этих испытаниях также определялись скорости распространения инициированных щелевых коррозионных атак при 15-50°C (59-122°F) и приложенном потенциале 150 мВ против SCE. Было обнаружено, что они примерно в десять раз ниже для SAF™ 2507, чем для сплава 6Mo+N.

Рисунок 11. Критические температуры питтинговой коррозии (КТК) при различных концентрациях хлорида натрия от 3 до 25% (потенциостатическое определение при +600 мВ SCE с поверхностью, отшлифованной наждачной бумагой зернистостью 600).

Рисунок 12. Критические температуры питтинговой коррозии (КТК) в 3% NaCl при различных значениях pH (потенциостатическое определение при +600 мВ SCE с поверхностью, отшлифованной наждачной бумагой зернистостью 600).

Коррозионная стойкость SAF™ 2507 в окисляющих хлоридных растворах иллюстрируется критическими температурами точечной коррозии (CPT), определенными в растворе «Зеленая смерть» (1% FeCl3 + 1% CuCl2 + 11 % H2SO4 + 1,2% HCl) и в растворе «Желтая смерть» (0,1% Fe2 ( SO4 ) 3 + 4 % NaCl + 0,01 M HCl). В таблице ниже приведены значения CPT для различных сплавов в этих растворах. Очевидно, что значения для SAF™ 2507 находятся на том же уровне, что и для никелевого сплава UNS N06625. Испытания демонстрируют хорошую корреляцию с рейтингом сплавов для использования в качестве труб подогревателей в системах десульфурации дымовых газов.

Критическая температура питтинга (КТП), определенная в различных испытательных растворах.

| Сплав | Критическая температура питтинга (КТП), °C «Зеленая смерть» |

«Желтая смерть» |

|---|---|---|

| САФ™ 2507 | 72,5 | >90 |

| 6Мо+N | 70 | >90 |

| УНС N06625 | 67,5 | >90 |

| АСTM 316 | <25 | 20 |

Коррозионное растрескивание под напряжением

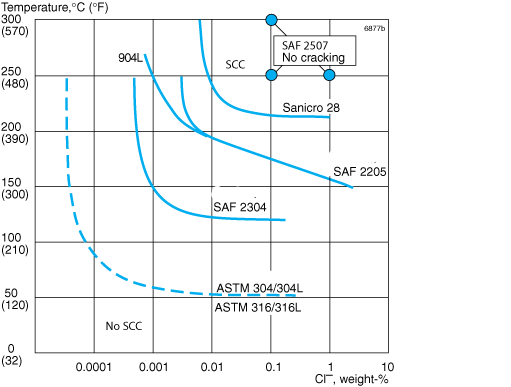

SAF™ 2507 обладает превосходной стойкостью к коррозионному растрескиванию под напряжением, вызванному хлоридами.

Стойкость SAF™ 2507 к КРН в хлоридных растворах при высоких температурах показана на рисунке 13. Признаки КРН отсутствуют до 1000 ppm Cl – /300 °C и 10000 ppm Cl – /250 °C.

Образцы U-образного изгиба SAF™ 2507, выдержанные в течение 1000 часов в горячем рассоле (108 °C, 226 °F, 25% NaCl), не показали трещин.

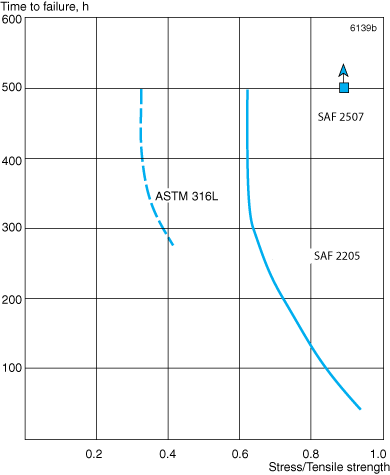

Пороговое напряжение для SAF 2507 ® в 40% CaCl 2 при 100 °C (210 °F) и pH = 6,5 превышает 90% предела прочности на растяжение как для основного металла, так и для сварных соединений (сварка TIG с Alleima® 25.10.4.L или сварка MMA с Alleima® 25.10.4.LR).

На рисунке 14 показан результат испытания в 40% CaCl 2 при 100 °C (210 °F), подкисленном до pH = 1,5. Подкисление стандартного испытательного раствора до pH = 1,5 снижает пороговое напряжение для SAF™ 2205, но не для SAF™ 2507. Это относится как к основному металлу, так и к сварным соединениям.

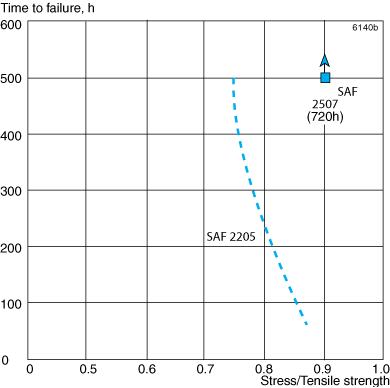

Пороговое напряжение как для основного металла, так и для сварных соединений SAF™ 2507 в кипящем 45% MgCl2 , 155°C (311°F) (ASTM G36) составляет приблизительно 50% от предела текучести.

Рисунок 13. Стойкость к SCC в нейтральных хлоридных растворах, содержащих кислород (около 8 ppm). Время испытания 1000 часов. Приложенное напряжение равно пределу текучести при температуре испытания.

Рисунок 14. Результаты испытаний SCC с постоянной нагрузкой в 40% CaCl 2 , pH = 1,5, при 100 °C (210 °F) с аэрированным испытательным раствором.

Рисунок 15. Испытания SCC при постоянной нагрузке в растворе NACE при комнатной температуре (NACE TM 0177).

На рисунке 15 показаны результаты испытаний SCC при комнатной температуре в тестовом растворе NACE TM0177 A (5% хлорида натрия и 0,5% уксусной кислоты, насыщенной сероводородом). На SAF™ 2507 трещин не наблюдалось, независимо от приложенного напряжения.

В водных растворах, содержащих сероводород и хлориды, коррозионное растрескивание под напряжением может также происходить на нержавеющих сталях при температурах ниже 60 °C (140 °F). Коррозионная активность таких растворов зависит от кислотности и содержания хлоридов. В отличие от случая с обычным коррозионным растрескиванием под напряжением, вызванным хлоридами, ферритные нержавеющие стали более чувствительны к этому типу коррозионного растрескивания под напряжением, чем аустенитные стали.

В соответствии со стандартом ISO 15156/NACE MR 0175 отожженная на твердый раствор и быстроохлажденная деформируемая сталь SAF™ 2507 пригодна для использования при температурах до 450 °F (232 °C) в кислых средах при добыче нефти и газа, если парциальное давление сероводорода не превышает 3 фунтов на кв. дюйм (0,20 бар).

SAF™ 2507 с максимальной твердостью 32 HRC, подвергнутый отжигу на твердый раствор и быстрому охлаждению в соответствии с NACE MR0103, пригоден для использования при переработке высокосернистой нефти.

Растрескивание под действием водорода (HISC)

Растрескивание под действием водорода (HISC) — это явление охрупчивания, которое может возникнуть в подводных стальных конструкциях с катодной защитой при наличии высоких растягивающих напряжений. При соединении с катодной защитой углеродистых сталей супердуплексные нержавеющие стали также будут катодно защищены, хотя это не обязательно. При преобладающих низких электрохимических потенциалах атомарный водород будет образовываться на стальных поверхностях за счет восстановления морской воды. Охрупчивание из-за HISC может возникнуть, когда водород диффундирует в металл.

Водород диффундирует гораздо быстрее в ферритной фазе, чем в аустенитной. Поэтому ферритные стали и стали, содержащие феррит, например, супердуплексные нержавеющие стали, более восприимчивы к HISC, чем аустенитные нержавеющие стали. Высокое механическое напряжение увеличивает риск HISC за счет увеличения скорости диффузии водорода, возникновения и распространения трещин в материале.

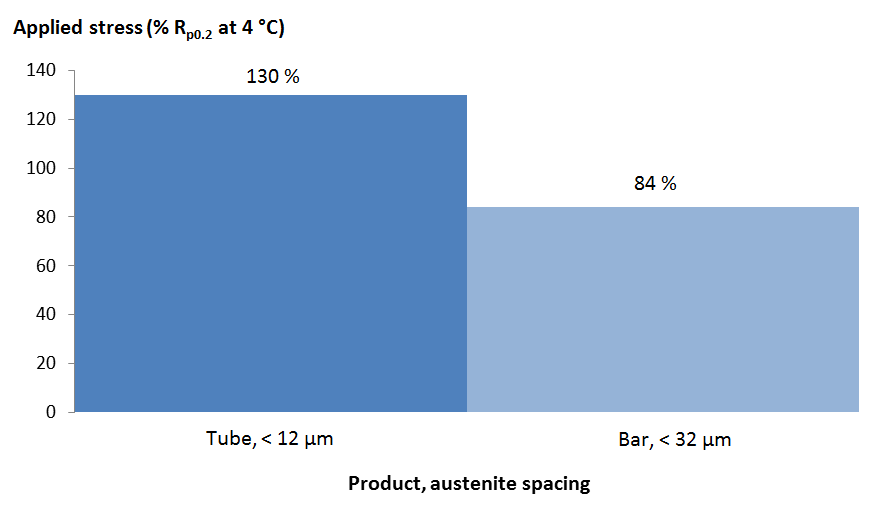

В супердуплексных нержавеющих сталях трещины имеют тенденцию распространяться в охрупченной ферритной фазе и останавливаться на границах фаз феррит-аустенит. Восприимчивость к HISC значительно увеличивается с увеличением расстояния между аустенитом. Поэтому крупнозернистые микроструктуры более восприимчивы. Программа испытаний, проведенная в Alleima Materials Technology, подтвердила, что склонность к HISC снижается, когда расстояние между аустенитом составляет менее 30 мкм, как рекомендовано DNV RP-F112. Холоднопильгерованные и отожженные на твердый раствор трубы с расстоянием между аустенитом от 5 до 15 мкм показали очень хорошую устойчивость к HISC при приложенном напряжении до 130% от предела текучести без образования трещин.

Допустимое напряжение без возникновения HISC для изделий с различным интервалом аустенита показано на рисунке 16.

Figure 16. Tolerable stress as a percentage of the actual yield strength at 4°C without HISC occurring is schematically shown for tube and bar products with different austenite spacing. SAF™ 2507 (UNS S32750) has been tested on hydrogen pre-charged tensile specimens, using constant load with a dead weight, with an applied potential of -1050 mV/SCE in a electrochemical cell with 3% NaCl solution at 4°C, 500 hours. [NACE paper no. 07498]

Intergranular corrosion

SAF™ 2507 is a member of the family of modern duplex stainless steels whose chemical composition is balanced to give quick reformation of austenite in the high temperature heat affected zone of a weld. This results in a microstructure that provides the material with good resistance to intergranular corrosion. SAF™ 2507 passes testing to ASTM A262 Practice E (Strauss test) without reservation.

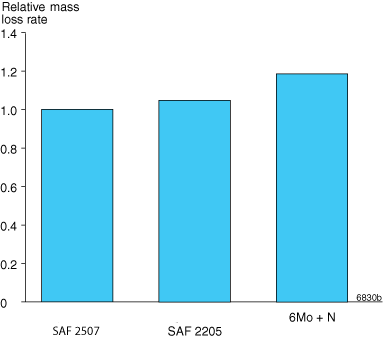

Erosion corrosion

The mechanical properties combined with corrosion resistance give SAF™ 2507 a good resistance to erosion corrosion. Testing in sand containing media has shown that SAF™ 2507 has an erosion corrosion resistance better than corresponding austenitic stainless steels. Figure 17 below shows the relative mass loss rate of the duplex SAF™ 2507, SAF™ 2205 and an austenitic 6Mo+N type steel after exposure to synthetic seawater (ASTM D-1141) containing 0.025-0.25% silica sand at a velocity of 8.9-29.3 m/s (average of all tests is shown).

Figure 17. Relative mass loss rate after testing of the resistance against erosion corrosion.

Corrosion fatigue

Duplex stainless steels which have a high tensile strength usually have a high fatigue limit and high resistance to both fatigue and corrosion fatigue.

The high fatigue strength of SAF™ 2507 can be explained by its good mechanical properties, while its high resistance to corrosion fatigue has been proven by fatigue testing in corrosive media.

PROCESSING

Hot Forming

2507 can be hot formed at temperatures ranging from 1875°F to 2250°F. This should be followed by a solution anneal at a minimum temperature of 1925°F, followed by a rapid air or water quench.

Cold Forming

Cold working 2507 can be accomplished using most typical stainless steel forming processes. Because the alloy has a higher yield strength than austenitic steels, but lower ductility, fabricators may need to use higher forming forces, larger bend radii, and springback allowances. Deep drawing, stretching, and other similar processes are more difficult for 2507 than for austenitic stainless steels. Solution annealing and quenching are recommended when the forming process requires more than 10% cold deformation.

Heat Treatment

Heat treatment for 2507 consists of solution annealing and quenching after hot or cold forming. Solution annealing should be performed at a minimum temperature of 1925°F. Annealing should be followed immediately by a rapid air or water quench. Heat treated items that are pickled and rinsed have excellent corrosion resistance.

Welding

2507 is weldable and can be joined to other materials using SMAW, GTAW, PAW, FCW, or SAW. When welding 2507, a 2507/P100 filler metal is recommended to ensure proper duplex weld construction.

2507 does not require preheating except to prevent condensation on cold metal. Interpass welding temperatures should not exceed 300°F or weld integrity will be compromised. To maximize corrosion resistance, root protection should be applied using either argon or 90% N2/10% H2 purge gas. The latter provides higher corrosion resistance.

What are the commonly used surfaces of stainless steel coils?

The surface finish of 201 stainless steel coil might vary depending on the cold rolling processing methods used and the surface treatment used after rolling. Surface treatments for stainless steel coils include NO.1, 2B, 4, HL, 6, 8, BA, TR hard, heavy rolling bright 2H, polished bright, and other surface treatments:

- NO.1: The surface obtained after hot rolling, heat treatment and pickling of stainless steel strip. It is used to remove the black oxide scale formed by pickling or similar processes during hot rolling and heat treatment. It ranks first in surface treatment. The No. 1 surface is silvery white and matte. It is generally used in heat-resistant and corrosion-resistant industries that do not require high surface gloss, such as the alcohol industry, chemical industry, large containers, etc.

- 2B: Unlike the 2D surface, the 2B surface is smoothed by a light roller, and the surface is brighter. The surface roughness Ra value measured by the equipment ranges from 0.1 to 0.5μm, which is a typical value for most processing types. This stainless steel strip surface has the strongest adaptability and is suitable for industries such as chemical, papermaking, petroleum, medical, and a wide range of fields such as building curtain walls.

- TR hard surface: TR stainless steel is also called hard steel. Its characteristic steel grades include 304 and 301, which are used for items that require high strength and hardness, such as railway vehicles, conveyor belts, springs and washers. The idea is to use the work hardening characteristics of austenitic stainless steel to improve the strength and hardness of steel plates through cold working methods such as rolling. In order to replace the gentle flatness of the 2B base surface, the hard material is gently rolled by a few percent to tens of percent, and no annealing is performed after rolling. Therefore, the TR hard surface of the hard material is the rolled surface after the cold rolling process.

- Re-rolled bright 2H: After the rolling operation, the stainless steel strip will be bright annealed. A continuous annealing line can be used to quickly cool the strip. The stainless steel strip travels along the line at a speed of 60-80m/min. After this process, the surface finish will be 2H re-rolled bright.

- No. 4: The No. 4 surface has a good polishing effect and is brighter than No. 3. It can also be obtained by polishing the cold-rolled stainless steel plate with a 2D or 2B surface, and then polishing the processed surface with a sanding belt with a particle size of 150-180#. The tool measures the surface roughness (Ra) between 0.2 and 1.5μm. The No. 4 surface is widely used in restaurants and cooking equipment, medical equipment, architectural decoration, containers and other applications.

- HL: The HL surface is often called a hairline finish. The Japanese JIS standard specifies a continuous hairline abrasive surface obtained by polishing with a 150-240# abrasive belt. The restrictions under the Chinese GB3280 standard are unclear. HL surface finish is commonly used for architectural decoration, such as elevators, escalators, and exterior walls.

- No. 6: The No. 6 surface is further polished on the basis of No. 4 with a Tampico brush or a W63 grit abrasive material specified in the GB2477 standard. The surface has good metallic luster, softness, weak reflection, and no imaging. Due to its good performance, it is very suitable for curtain walls, tassel decoration, and cooking supplies.

- BA: BA is a surface that is brightly heat treated after cold rolling. Bright heat treatment is annealing in a protective atmosphere to ensure that the surface is not oxidized and retain the gloss of the cold-rolled surface, and then it is polished with a high-precision smooth roller to improve the surface brightness. The instrument evaluates the surface roughness to be 0.05-0.1μm, indicating that the surface is close to a mirror surface. BA surfaces can be used in a variety of applications, including food utensils, household appliances, medical equipment, automotive parts, and decorations.

- № 8: Зеркальная поверхность, максимальная отражательная способность, отсутствие абразивных частиц. Индустрия глубокой обработки нержавеющей стали также относится к 8K-доске. Материал BA часто используется в качестве сырья для обработки зеркал. Его нужно только отполировать. Поверхность красива после обработки зеркалом и часто используется для входов в здания и внутренней отделки.

Какова стандартная морская упаковка рулонной нержавеющей стали марки 2507?

- Стандартная экспортная морская упаковка:

водонепроницаемая бумажная обмотка + ПВХ-пленка + обвязка лентой + деревянный поддон или деревянный ящик; - Индивидуальная упаковка по вашему запросу (на упаковке допускается печать логотипа или другого содержимого);

- Другая специальная упаковка будет разработана по запросу клиента;

доступны как варианты «глазом к стене», так и «глазом к небу»; - Международная экспресс-доставка: DHL/UPS/FEDEX/EMS и наша собственная экспресс-линия;

- По воздуху, морю или суше;

- Порт отправки: Шанхай, Нинбо, Циндао, Тяньцзинь или по вашему запросу.

Свяжитесь с поставщиками рулонной нержавеющей стали.

- Вы можете легко заказать рулоны нержавеющей стали любого размера и количества онлайн.

Кроме того, наша дружелюбная команда по продажам будет рада принять ваш заказ. Просто позвоните +86 13382898899 или напишите по электронной почте Daxunhejin@gmail, и мы свяжемся с вами как можно скорее.

Пожалуйста, заполните форму на странице «Связаться с нами» или позвоните нашему менеджеру по продажам по телефону «+86 13382898899», мы свяжемся с вами как можно скорее. Наш WhatsApp в сети, а электронная почта ([email protected]) будет проверена в течение 6 часов. На каждый запрос или сообщение будет дан оперативный ответ. Кроме того, мы каждую неделю делимся рыночной информацией с нашими клиентами

Образцы могут быть предоставлены бесплатно, но расходы на доставку несет заказчик, и они будут возвращены после сотрудничества.

Мы экспортируем продукцию в более чем 42 страны, такие как Канада, Чили, Кувейт, Германия, Южная Корея, Саудовская Аравия, Сингапур и т. д.

Минимальный объем заказа составляет 1 тонну рулона нержавеющей стали.

У нас есть полная организация от закупки сырья до обработки и организации отгрузки. Во всей цепочке документальные люди и QC будут искать и проверять его по точным требованиям. Инспекция третьей стороны приветствуется.

Пробные заказы могут быть доставлены в течение недели. Для обычных заказов это занимает около двух недель.