410 пруток нержавеющий

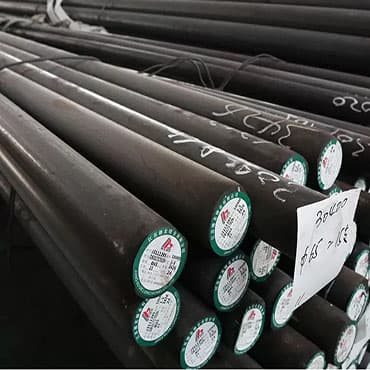

Являясь ведущим поставщиком и экспортером нержавеющей стали в Китае, компания Daxun поставляет прутки (круглые прутки) из нержавеющей стали по всему миру.

- Марка: AISI 410-12Cr13

- Производство: горячекатаный, холоднотянутый, кованный

- Стандарты: ASTM, ASME, GB, DIN, JIS, ISO.

- Он магнитен как в отожженном, так и в закаленном состоянии.

- Различные методы нагрева дают различные свойства

- Высокая коррозионная стойкость к кислотам: азотной кислоте, серной кислоте

Global leader in stainless rod and Round Bar fabrication services

Круглый пруток из нержавеющей стали ASTM A479 AISI 410, квадратный пруток ASTM A479 SS 410, плоский пруток из нержавеющей стали 410, пруток из нержавеющей стали 410, широкий ассортимент круглых прутков из нержавеющей стали 410, круглые прутки SS 410, производители круглых прутков SS DIN 1.4006, купить блестящий пруток из нержавеющей стали 410, полированный пруток 410 SS, поставщики прутка SS 410, производители круглых прутков AISI SS 410 в Китае.

Пруток из нержавеющей стали 410 — это мартенситная нержавеющая сталь, которая обеспечивает отличную коррозионную стойкость, прочность и твердость. Эта сталь магнитна как в отожженном, так и в закаленном состоянии, и с помощью различных видов термической обработки можно получить различные свойства.

Одним из главных преимуществ прутка из нержавеющей стали 410 является его высокая коррозионная стойкость, что делает его пригодным для различных ситуаций. Это включает в себя применение внутри и вне помещений, а также ситуации с агрессивными химикатами, кислотами и другими едкими соединениями.

Пруток из нержавеющей стали 410 не только устойчив к коррозии, но также прочен и долговечен. Это делает его идеальным для использования в отраслях, где требуются прочные и долговечные материалы, таких как автомобильные приводные валы и аэрокосмическая промышленность.

Термическая обработка является важнейшей частью обработки прутка из нержавеющей стали 410. Различные процедуры термической обработки могут использоваться для улучшения определенных качеств стали, таких как прочность, пластичность и твердость. Эти методы термической обработки включают отжиг, закалку и отпуск.

История прутка из нержавеющей стали 410

Американский институт чугуна и стали (AISI) разработал нержавеющую сталь 410 в начале двадцатого века. Это мартенситная нержавеющая сталь, что означает, что она содержит не менее 11,5% хрома. Этот сплав был разработан для улучшения коррозионной стойкости стандартной углеродистой стали за счет добавления хрома.

В первые дни круглый пруток из нержавеющей стали 410 в основном использовался для производства и строительства инструментов и оборудования. Его превосходная прочность и коррозионная стойкость сделали сталь идеальной для долгосрочного использования.

Во время Второй мировой войны спрос на круглый пруток из нержавеющей стали 410 вырос, поскольку он использовался для изготовления военной техники, такой как танки и подводные лодки. Это укрепило его имидж как надежного и долговечного материала.

В послевоенный период нержавеющая сталь 410 нашла все более широкий спектр применения, особенно в автомобильной и аэрокосмической промышленности. Его превосходная прочность и коррозионная стойкость сделали его идеальным для использования в суровых условиях. В 1960–1970-х годах нержавеющая сталь марки 410 стала пользоваться все большей популярностью в кулинарии и медицине после того, как было обнаружено, что она является подходящим материалом для изготовления посуды, хирургических инструментов и оборудования для переработки пищевых продуктов.

Наша сеть сервисных центров располагает складом прутков из нержавеющей стали для быстрой и готовой поставки прутков обычных размеров и сплавов. Мы также производим прутки из нержавеющей стали по индивидуальным размерам и можем составить графики поставок для быстрого выполнения заказов в установленные сроки, если объемы окажутся ниже минимально допустимых на заводе. Компания Daxun Alloys располагает складом круглых прутков из нержавеющей стали диаметром от 1/16″ до 26″. Круглые прутки доступны почти из всех марок нержавеющей стали, включая 302, 303, 304/L, 309/S, 310/S, 316/L, 317/L, 321, 321/H, 347, 347H, 410, 416, 420, 440C, 17-4PH, Duplex 2205 и Alloy 20. Закаленные круглые прутки из нержавеющей стали предлагаются в 17-4PH, закалке H900 (по запросу), H1025, H1150, Double H1150 и H1150M. Другие закаленные закалки могут быть изготовлены по запросу. Мы поставляем следующие виды нержавеющей стали 400-й серии: 410, 430 и 416. Мы также поставляем прецизионные и подшипниковые прутки из нержавеющей стали 303, 304 и 316/L. Большая часть нашего инвентаря состоит из наших уникальных сортов обработанных прутков: прутков из нержавеющей стали, которые плавятся в соответствии со стандартами для повышения обрабатываемости и снижения общей стоимости компонента. Наше оборудование для обработки прутков из нержавеющей стали позволяет Daxun Alloys производить продукцию в точном соответствии с техническими требованиями наших клиентов.

- Параметр

- Ингредиенты

- Механические свойства

- ФИЗИЧЕСКИЕ СВОЙСТВА

- Все эквивалентно

- Типы

| Спецификация круглого прутка ASTM A479 410 | ГОСТ 5949-75,ГОСТ 2590-2006,ГОСТ 5582-75 ASTM A479 / ASTM A479 / ASTM A182 / ASME SA479 / ASME SA479 / ASME SA182 |

| Процесс производства круглого прутка ASTM A479 410 | Горячая прокатка / Холодная прокатка / Горячая ковка / Прокатка / Механическая обработка |

| Круглый пруток ASTM A479 410 Другие марки | 202 / 304 / 304L / 304H / 309S / 310S / 316 / 316L / 316Ti / 317L / 321 / 321H / 347 / 347H / 904L и т. д. |

| Номер UNS – UNS S30400, UNS S30403, UNS S31008, UNS S31620, UNS S31603, UNS S31603, UNS S31635, UNS S31703, UNS S32100, UNS S34700, UNS S34709, UNS S8904 | |

| № DIN/EN – 1.4301, 1.4307, 1.4845, 1.4401, 1.4404, 1.4571, 1.4438, 1.4541, 1.4550, 1.4551, 1.4539 | |

| АФНОР: Z2 CN 18.10, Z 6 CND 17-11, Z 2 CND 17-12, Z3 CrNi 22.05 AZ | |

| ЕВРОНОРМА: FeMi35Cr20Cu4Mo2, FeMi35Cr20Cu4Mo2, X1CrNiMo17 12 2, X3CrNiMo17 12 2, FeMi35Cr20Cu4Mo2, X2CrNiMoN 22.5.3 | |

| Размер круглого прутка ASTM A479 410 | Круглые прутки: наружный диаметр в диапазоне от 4 мм до 500 мм. |

| Яркие полосы: наружный диаметр в диапазоне от 4 мм до 200 мм | |

| Шестигранные стержни: от 18 мм до 57 мм (от 11/16″ до 2-3/4″) | |

| Квадратные прутки: от 18 мм до 57 мм (от 11/16″ до 2-3/4″) | |

| Плоские прутки: от 1/2″ до 10″ толщиной от 2 мм до 150 мм, доступны плоские прутки из нержавеющей стали нестандартных размеров | |

| Длина круглого прутка ASTM A479 410 | От 2 до 7,5 метров (от 8 до 24 футов) или индивидуальная длина в соответствии с требованиями |

| ASTM A479 410 Круглые прутки и формы | Круглый, квадратный, шестигранный (A/F), прямоугольный, биллет, слиток, HRAP, блестящий, вал, поковка и т. д. |

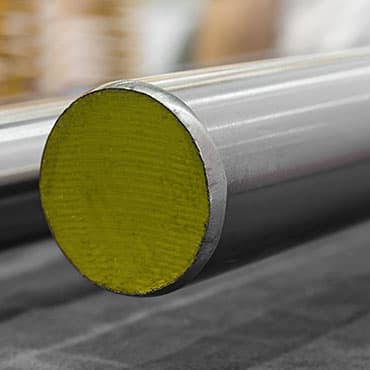

| Круглый пруток ASTM A479 410 Отделка | Черный, полированный, грубая обработка, отделка № 4, матовая отделка, отделка BA |

| Стандарт размеров круглого прутка ASTM A479 410 | ASTM A 484 / ISO h11 / ISO K12 Допуски F8 / h8, h9, h10, h11, h12, k12, k13, A-484, EN-10060, DIN-1013 и т. д. |

| Термообработка круглого прутка по стандарту ASTM A479 410 | Состояние А, в котором прутки отожжены |

| Состояние H, при котором прутки закалены и отпущены при относительной температуре | |

| Состояние T, при котором прутки закалены и отпущены при относительно высокой температуре | |

| Состояние S, в котором прутки подвергаются деформационному упрочнению или относительно легкой холодной обработке. | |

| Состояние B, в котором прутки подвергаются относительно жесткой холодной обработке. | |

| Отжиг на твердый раствор, старение и двойное старение | |

| ASTM A479 410 Обработка поверхности круглого прутка | Бесцентровая шлифовка и ленточная полировка до значения Ra = 0,2 мкм (среднеквадратичное значение 12) и полировка зернистостью от 180 до 600 |

| ASTM A479 410 Снятие фаски с круглого прутка | Доступно в 30°, 45° и 60° с помощью полностью автоматического двустороннего фаскоснимателя |

| Другие испытания круглого прутка ASTM A479 410 | NACE MR0175, IGC TEST, испытание на межкристаллитную коррозию согласно ASTM A262 Practice E, испытание на удар по Шарпи, макросъемка, размер зерна, твердость, магнитопорошковая дефектоскопия (MPI), 100% тестирование с помощью цифрового ультразвукового дефектоскопа согласно ASTM A-388, EN 10308 (класс 1–4), API 6A/ISO 10423:2003-PSL3, SEP 1920:1984 (класс A, B, C), MIL STD 2154 и т. д. |

| Услуги по производству круглого прутка ASTM A479 410 с добавленной стоимостью | Прокатка, сверление, перфорация, обработка на станках с ЧПУ, пескоструйная обработка, дробеструйная обработка, термообработка, антикоррозийная покраска, полировка |

| Упаковка круглого прутка ASTM A479 410 | Насыпью / Каррата / Деревянный поддон / Деревянный ящик / Пластиковая тканевая обертка |

| Отгрузка и транспортировка круглого прутка ASTM A479 410 | По дороге – Грузовик / Поезд Частичная загрузка, Полная загрузка, По морю – Конвенциональное судно для перевозки генеральных грузов / FCL (Полная загрузка контейнера) / LCL (Меньшая загрузка контейнера) / 20-футовый контейнер / 40-футовый контейнер / 45-футовый контейнер / Контейнер High Cube / Контейнер с открытым верхом, По воздуху – Грузовые гражданские пассажирские и грузовые самолеты |

| Сертификат испытаний круглого пруткового материала ASTM A479 410 | Сертификат испытаний производителя согласно EN10204 3.1, 3.2 / Сертификат лабораторных испытаний от лаборатории, одобренной NABL. / Под сторонним инспекционным агентством, таким как SGS, TUV, DNV, LLOYDS, ABS, Бюро стандартов Китая, одобрено BIS и т. д. |

| Документация на круглый пруток ASTM A479 410 | Коммерческий счет-фактура, включающий код HS / Упаковочный лист, включая вес нетто и вес брутто, количество коробок, маркировку и номера / Сертификат происхождения, легализованный/заверенный Торговой палатой или посольством / Сертификаты фумигации / Отчеты об испытаниях сырья / Записи о прослеживаемости материалов / План обеспечения качества (QAP) / Карты термообработки / Сертификаты испытаний, подтверждающие NACE MR0103, NACE MR0175 / Сертификаты испытаний материалов (MTC) в соответствии с EN 10204 3.1 и EN 10204 3.2 / Гарантийное письмо / Утвержденные NABL отчеты о лабораторных испытаниях / Спецификация процедуры сварки/Запись квалификации процедуры, WPS/PQR / Форма A для целей Общей системы преференций (GSP) |

| Номер UNS | S41000 |

| RU | 1.4006 |

| АИСИ | 410 |

| Углерод (С) | 0,08/0,15 |

| Кремний (Si) | 1 |

| Марганец (Mn) | 1 |

| Фосфор (P) | 0,04 |

| Сера (S) | 0,03 |

| Хром (Cr) | 11.5/13.5 |

| Молибден (Mo) | |

| Никель (Ni) | 0,75 |

| Свойство | Ценить |

| Плотность | 7,8 г/см3 |

| Предел текучести | 1225 МПа при деформации 0,2% |

| Предельная прочность на растяжение | 1525 МПа |

| Твёрдость | 126–192 Твердость по Бринеллю (в отожженном состоянии) 201–255 Твердость по Бринеллю (в закаленном и отпущенном состоянии) |

| Модуль объемной упругости | 200 ГПа |

| Температура плавления | 1480–1530 °С |

| Коррозионная стойкость | Хорошая коррозионная стойкость в мягких атмосферных средах, воде и некоторых мягких химических средах. Она демонстрирует точечную коррозию и коричневые пятна в условиях соленой воды и обеспечивает более низкую стойкость к кислотным средам, чем альтернативы из аустенитной нержавеющей стали. |

| Магнетизм | Проницаемость 700–1000. Высокочувствителен к магнитным полям, действует как сильный носитель магнитного потока благодаря своей мартенситной структуре. |

| Плотность (фунт/дюйм^2) при комнатной температуре | 0,28 | |

| Модуль упругости при растяжении (psi x 10^6) | 29 | |

| Удельная теплоемкость (БТЕ/o F/фунт) | от 32 до 212 oF | 0.11 |

| Теплопроводность (БТЕ/ч/фут^2/фут) | 212oF | 14.4 |

| 932oF | 16.6 | |

| Средний коэффициент теплового расширения (дюйм x 10^-6 на o F) | от 32 до 212oF | 5.5 |

| от 32 до 1200oF | 6.5 | |

| Удельное электрическое сопротивление (мкОм – см) | при 70oF | 22.5 |

| СТАНДАРТ | ВЕРКСТОФФ НОМЕР. | УНС | БС | RU | JIS |

| СС 410 | 1.4006 | S41000 | 410С21 | X12Cr13 | СУС 410 |

| Стержни из нержавеющей стали 410 | 410 SS резьбовые стержни самые массивные в Индии |

| Круглые прутки из нержавеющей стали 410 | Холоднотянутые и полированные квадратные прутки из нержавеющей стали 410 |

| Прутки из нержавеющей стали ASTM A479 410 | Аустенитный пруток из нержавеющей стали ASTM Bright 410 |

| Круглые прутки SS UNS S41000 | СС ВЕРКСТОФФ Н.Р. 1.4845 Круглые стержни |

| Производитель стержней из нержавеющей стали ASTM A479 410 | Дилеры шестигранных прутков из нержавеющей стали 410 |

| Производитель стальных стержней для полировки A479 410 | Холоднотянутые прутки из нержавеющей стали 410 Держатель запаса |

| Распределители черных прутков из нержавеющей стали SUS 410 | Поставщики полых прутков из быстрорежущей стали из нержавеющей стали 410 |

| Пружинные стержни из высококачественной нержавеющей стали 410 | ASME, ASTM, EN, BS, GB, плоские прутки из нержавеющей стали 410 |

| Экспортер слитков из нержавеющей стали 410 Bright | Круглый пруток из нержавеющей стали AISI ASTM 410 |

| Круглые кованые прутки из нержавеющей стали AISI 410 | Холоднокатаные прутки из нержавеющей стали 410 |

Выбирайте Daxun и сделайте своих клиентов довольными.

Быстрый ответ-стержень из нержавеющей стали 410

Мы обеспечиваем клиентов своевременной и быстрой доставкой прутков из нержавеющей стали 410. За скоростью стоит системная поддержка от информационного потока до логистики и движения капитала. Например, с точки зрения информационного потока данные о заказах Daxun передаются в логистическую систему в режиме реального времени, и данные бесшовно связаны; с точки зрения логистики центр обработки находится недалеко от портов, рек и морей, с разумным планированием, быстрым реагированием, складскими и транспортными связями и эффективной загрузкой, что гарантирует выполнение задачи в срок.

Преимущества Даксуна

- Разновидности: Мы предлагаем широкий ассортимент размеров и марок, включая серии 300, 400, 600 и другие.

- Гибкость: независимо от того, нужны ли вам горячекатаные или холоднотянутые прутки, длина наших прутков из нержавеющей стали подбирается в соответствии с требованиями вашего конкретного проекта.

- Стандарты качества: стержень из нержавеющей стали 410 соответствует строгим стандартам ASTM, ISO9001, GB, NSF/ANSI, что гарантирует надежность и производительность.

- Индивидуальные заказы: Ищете специальные размеры прутков из нержавеющей стали? Мы предлагаем различные варианты изготовления прутков из нержавеющей стали по конкурентоспособным ценам и с удобным онлайн-заказом.

Упаковка стержня из нержавеющей стали 410

Мы уделяем внимание каждому процессу 416 круглых прутков, чтобы гарантировать качество. Упаковка, которую мы обычно применяем, заключается в упаковке круглых прутков из нержавеющей стали в экологически чистые пластиковые пакеты, а затем в деревянные ящики или деревянные поддоны без фумигации. Также можно обсудить индивидуальную упаковку, например OEM. Мы предоставляем почти все, чтобы удовлетворить ваши требования к упаковке круглых прутков. Мы придаем большое значение упаковке. Круглые прутки упаковываются в деревянные гофрированные коробки, обернутые пластиковой упаковкой и пузырчатой пленкой снаружи.

Качество, доставка, проверка

- Daxun также проводит несколько испытаний на обеспечение качества. Эти испытания включают испытание на сплющивание, испытание на питтинг и сопротивление, механическое испытание, испытание на твердость, положительную идентификацию материала, испытание на расширение и т. д. Все эти испытания гарантируют, что материал подходит для требуемого применения.

- В процессе производства мы измеряем диаметр, толщину и поверхность изделия. Наш стандартный срок поставки составляет 7-15 дней, за исключением некоторых изделий специального размера, срок поставки увеличивается до 20 дней.

Срок поставки строго соответствует договору. - Поддержка сторонних агентств-клиентов при посещении завода для проведения инспекции

- Предоставляем бесплатные образцы клиентам для тестирования

- Поддержка инспекции завода на месте или видеоинспекции

Техническая поддержка

Если вам нужна дополнительная техническая помощь, наш местный металлург и знающий персонал будут рады помочь. Кроме того, Daxun может похвастаться сертифицированной испытательной лабораторией — первой в отрасли многометаллического и пластикового инвентаря. Это, по нашему мнению, демонстрирует нашу непоколебимую преданность качеству и нашу философию как поставщика полного спектра услуг.

Информация для заказа стержня из нержавеющей стали 410

410 Круглый пруток Заказы на закупку должны включать количество, класс PSL, тип или категорию, ссылку API5L, диаметр, отделку поверхности, длину и любые применимые приложения или дополнительные требования, связанные с химическим составом, механическими свойствами, термической обработкой, дополнительными испытаниями, производственным процессом, отделкой поверхности или обработкой концов. Прутки подвергаются светлому отжигу на твердый раствор.

Характеристики стержня из нержавеющей стали SS410

Daxun Alloy Позвольте вашему бренду быстро улучшиться

- Галерея

- Состояние доставки

- Возрастная закалка

| Выбор штата доставки | Состояние поверхности |

| Кованый | Черный |

| Полированный | |

| Горячекатаный | Черный |

| Полированный | |

| Яркий | |

| Маринованный | |

| Холоднотянутый | Полированный |

| Яркий | |

| Примечание: | |

| 1. Если вам требуется другой штат доставки, чем указанный выше, пожалуйста, уточните у нас. | |

| 2. В случае возникновения каких-либо вопросов или заказов, пожалуйста, сообщите нам о любых дополнительных требованиях, не указанных здесь. | |

| Материал в состоянии, подвергнутом отжигу на твердый раствор, может быть подвергнут старению следующим образом: *Обозначает двойное старение | ||||||||||||

| Состояние | Н900 (Н480) | Н925 (Н495) | Н1025 (Н550) | Н1075 (Н580) | Н1100 (Н595) | Н1150 (Н620) | Н1150М (Н620М)* | Плюс | H1150D (H620D)* | Плюс | ||

| Нагреть до | ±15oF | 900oF | 925 градус по Фаренгейту | 1025oF | 1075oF | 1100oF | 1150oF | 1400oF | 1150oF | 1150oF | 1150oF | |

| ±9oC | 480оС | 495oC | 550oC | 580oC | 595oC | 620oC | 760oC | 620oC | 620oC | 620oC | ||

| Удерживать в течение нескольких часов | 1 | 4 | 4 | 4 | 4 | 4 | 2 | 4 | 4 | 4 | ||

| Охлаждение до температуры ниже | Воздух | Воздух | Воздух | Воздух | Воздух | Воздух | Воздух | Воздух | Воздух | Воздух | ||

| 90oF (32oC) | ||||||||||||

Типы стержней из нержавеющей стали SS 410 (6)

Информация доступна для ознакомления и скачивания

Daxun — надежный производитель прутков и стержней из нержавеющей стали.

Как профессиональный производитель, Daxun гарантирует, что вся производимая нами продукция отличается высоким качеством. Поэтому мы гарантируем, что все прутки из нержавеющей стали сертифицированы по стандартам ISO9001, SGS, CE, OQC

я долговечна, премиальна и высокопроизводительна.

Сопутствующие товары (12)

Ведущие поставщики прутков и стержней из нержавеющей стали в Китае

- ОБЩИЕ СВОЙСТВА

Стандартный пруток из мартенситной нержавеющей стали 410 используется для деталей, подвергающихся сильным нагрузкам, и обладает превосходной коррозионной стойкостью в дополнение к высокой прочности и твердости. Круглый пруток из сплава 410 содержит минимум 11,5% хрома, что достаточно для проявления коррозионной стойкости в паре, многих умеренных химических условиях и мягких атмосферах. Этот сорт общего назначения обычно поставляется в закаленном, но обрабатываемом состоянии для применений, требующих высокой прочности и умеренной стойкости к нагреву и коррозии. Самая высокая коррозионная стойкость достигается, когда круглый пруток 410 полируется, закаливается и закаляется. Характеристики: UNS S41000

ПРИЛОЖЕНИЯ:

- Столовые приборы

- Лопатки паровых и газовых турбин

- Кухонная утварь

- Болты, гайки, винты

- Детали и валы насосов и клапанов

- Коврики для шахтерских лестниц

- Стоматологические и хирургические инструменты

- Насадки

- Шарики и седла из закаленной стали для насосов нефтяных скважин

КОРРОЗИОННАЯ УСТОЙЧИВОСТЬ:

- Хорошая коррозионная стойкость к коррозии на воздухе, в местах со слабокоррозионными условиями и питьевой водой. При надлежащей очистке после использования, воздействие повседневной деятельности (спорт, приготовление пищи) в целом удовлетворительно. Высокая стойкость к низким концентрациям умеренных органических и минеральных кислот и не подвержен коррозии

Функции:

- Он магнитен как в отожженном, так и в закаленном состоянии.

- При нагревании различными способами проявляется широкий спектр свойств.

- Демонстрирует большую коррозионную стойкость к кислотам: азотной, серной и т. д.

Доступные размеры на складе:

проверяйте страницы конкретных продуктов на наличие уникальных размеров и обращайтесь к нам за расценками на любой заказ нестандартного размера.

Круглые прутки из нержавеющей стали марки SS 410

Круглые прутки из нержавеющей стали 410 широко используются. Они широко используются в различных областях от строительства до автомобильных деталей. Благодаря широкому спектру применения Daxun Alloys предлагает круглые прутки из нержавеющей стали различных марок и размеров. Благодаря нашему бесплатному расширенному сервису резки мы можем точно удовлетворить ваши требования каждый раз.

Широкий выбор размеров

Круглые прутки из нержавеющей стали 410 можно легко заказать в широком диапазоне размеров. Просто выберите марку стали, которая вам нужна, и мы предоставим прутки длиной от 500 мм до 6 метров и диаметром от 3 мм до 500 мм. Мы даже предоставляем вам возможность заказа в метрических или имперских размерах.

Если вам нужно что-то нестандартного размера, это не проблема. Мы предлагаем неограниченное количество бесплатных отрезов по длине. Используя самые современные ленточные пилы для обеспечения точности и повторяемости, мы можем точно соответствовать вашим требованиям каждый раз. Просто дайте нам знать при заказе.

Свяжитесь с вашим поставщиком круглого прутка из нержавеющей стали

Независимо от того, ищете ли вы разовый заказ или долгосрочный план пополнения запасов, мы предлагаем различные сорта круглого прутка из нержавеющей стали для удовлетворения ваших потребностей! Усильте свой производственный процесс с помощью высококачественного круглого прутка из нержавеющей стали от Daxun Alloy. Свяжитесь с нами сегодня, чтобы адаптировать превосходные решения по металлу под ваши конкретные потребности!

Заказать круглые прутки из нержавеющей стали просто. Наш сайт предлагает простой пошаговый процесс. Кроме того, вы можете позвонить в нашу службу продаж по телефону +8613382898899. Если у вас есть какие-либо вопросы, отправьте нам электронное письмо по адресу [email protected], и наша команда свяжется с вами как можно скорее.

Мы можем предоставить образцы прутков из нержавеющей стали 410 для проверки качества. Образец бесплатный, вы платите только за доставку.

Мы экспортируем продукцию в более чем 42 страны, такие как Канада, Чили, Кувейт, Германия, Южная Корея, Саудовская Аравия, Сингапур и т. д.

Минимальный заказ составляет 1 тонну прутка из нержавеющей стали марки 410.

Пробные заказы могут быть доставлены в течение недели. Для обычных заказов это занимает около двух недель.