17-4PH пруток нержавеющий

Являясь ведущим поставщиком и экспортером нержавеющей стали в Китае, компания Daxun поставляет прутки (круглые прутки) из нержавеющей стали по всему миру.

- Марка: AISI 17-4PH-SUS630

- Производство: горячая прокатка, холодное волочение, ковка

- Стандарт: ГОСТ, ASTM, ASME, GB, DIN, JIS, ISO

- Высокая прочность

- Высокая твердость

- Износостойкость

- Поддается термической обработке

Мировой лидер в сфере услуг по изготовлению прутков из нержавеющей стали и круглого проката

Daxun — мировой производитель ассортимента круглых прутков/стержней SS 17-4PH/630. Мы являемся поставщиком, экспортером и авторитетным дистрибьютором высококачественных прутков и стержней.

Мы предлагаем нашим клиентам прутки и стержни с различными параметрами, включая обработку поверхности, отделку концов, размеры, формы и размеры.

SS 17-4PH — это мартенситная нержавеющая сталь, которая упрочняется осаждением. Однако сплав включает в себя легирующие элементы, такие как никель, медь и хром. Сплав широко используется в аэрокосмической отрасли для крепежных деталей и других структурных компонентов. UNS S17400 имеет микроструктуру, полученную из сплава в процессе переплавки. Улучшенная структура сплава повышает его прочность.

Нержавеющая сталь 17-4 PH Round Bar — популярный и адаптируемый материал в обрабатывающей промышленности и машиностроении благодаря своей превосходной коррозионной стойкости, высокой прочности и простоте производства. «PH» в 17-4 PH относится к упрочнению осаждением, которое представляет собой процедуру термической обработки, которая улучшает механические свойства материала.

Наша сеть сервисных центров располагает складом прутков из нержавеющей стали для быстрой и готовой поставки прутков обычных размеров и сплавов. Мы также производим прутки из нержавеющей стали по индивидуальным размерам и можем составить графики поставок для быстрого выполнения заказов в установленные сроки, если объемы окажутся ниже минимально допустимых на заводе. Компания Daxun Alloys располагает складом круглых прутков из нержавеющей стали диаметром от 1/16″ до 26″. Круглые прутки доступны почти из всех марок нержавеющей стали, включая 302, 303, 304/L, 309/S, 310/S, 316/L, 317/L, 321, 321/H, 347, 347H, 410, 416, 420, 440C, 17-4PH, Duplex 2205 и Alloy 20. Закаленные круглые прутки из нержавеющей стали предлагаются в 17-4PH, закалке H900 (по запросу), H1025, H1150, Double H1150 и H1150M. Другие закаленные закалки могут быть изготовлены по запросу. Мы поставляем следующие виды нержавеющей стали 400-й серии: 410, 430 и 416. Мы также поставляем прецизионные и подшипниковые прутки из нержавеющей стали 303, 304 и 316/L. Большая часть нашего инвентаря состоит из наших уникальных сортов обработанных прутков: прутков из нержавеющей стали, которые плавятся в соответствии со стандартами для повышения обрабатываемости и снижения общей стоимости компонента. Наше оборудование для обработки прутков из нержавеющей стали позволяет Daxun Alloys производить продукцию в точном соответствии с техническими требованиями наших клиентов.

- Параметр

- Ингредиенты

- Механические свойства

- ФИЗИЧЕСКИЕ СВОЙСТВА

- Все эквивалентно

- Типы

| Параметры продукта: стержень из нержавеющей стали | |

| Технические характеристики | ГОСТ 5949-75,ГОСТ 2590-2006,ГОСТ 5582-75 ASTM A276, ASME SA276 / ASTM A479 ASME SA479 |

| Размеры | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Круглые прутки SS 17-4PH | Наружный диаметр в диапазоне от 4 мм до 500 мм |

| Круглые прутки SS 17-4PH | Внешний диаметр в диапазоне от 4 мм до 100 мм |

| Круглые прутки SS 17-4PH | 18 мм – 57 мм (от 11/16″ до 2-3/4″) |

| Заканчивать | Черный, полированный, грубая обработка, отделка № 4, матовая отделка, отделка BA |

| Длина | От 1 до 6 метров, индивидуальная длина отрезка |

| Форма | Круг, квадрат, шестигранник (A/F), прямоугольник, заготовка, слиток, поковка и т. д. |

| Углерод | 0,07% (макс.) |

| Кремний | 1.00% (макс.) |

| Марганец | 1.00% (макс.) |

| Фосфорный | 0,040% (макс.) |

| Сера | 0,030% (макс.) |

| Хром | 15%-17,5% |

| Молибден | 0,50% (макс.) |

| никель | 3%-5% |

| Медь | 3%-5% |

| Тип материала | Состояние | Предел прочности на разрыв (PSI) | 0,2% Предел текучести (PSI) | Удлинение (% в 2 дюймах) | Уменьшение площади (%) | Твёрдость по Бринеллю | Твёрдость по Роквеллу |

| 17-4 ФС | H900 | 190,000 | 170,000 | 10 | 40 | 388 | С40 |

| Н1025 | 155,000 | 145,000 | 12 | 45 | 331 | С35 | |

| H1075 | 145,000 | 125,000 | 13 | 45 | 311 | С32 | |

| H1150 | 135,000 | 105,000 | 16 | 50 | 277 | С28 | |

| H1150-М | 115,000 | 75,000 | 18 | 55 | 255 | С24 | |

| H1150-D | 125,000 | 105,000 | 16 | 50 | 255 мин – 311 макс | С24 – 33 |

| Состояние термообработки | H900 |

| Плотность, фунт/дюйм3 | 0,282 |

| Удельное электрическое сопротивление, мкОм-см | 77 |

| Удельная теплоемкость, БТЕ/фунт/°F (32-212°F) | 0.1 |

| Теплопроводность, БТЕ/ч/фут2/дюйм/°F | |

| 300°F | 124 |

| 500°F | 135 |

| 860°F | 156 |

| 900°F | 157 |

| Средний коэффициент теплового расширения, дюйм/дюйм/°F | |

| -100 до 70°F | 5,8 х 10^-6 |

| 70 – 200°F | 6,0 х 10^-6 |

| 70 – 400°F | 6,0 х 10^-6 |

| 70 – 600°F | 6,3 х 10^-6 |

| 70 – 800°F | 6,5 х 10^-6 |

| 70 – 900°F | — |

| Модуль упругости, тыс.фунтов на кв.дюйм | 28,5 х 10^3 |

| Модуль жесткости, тыс.фунтов на кв.дюйм | 11,2 х 10^3 |

| Коэффициент Пуассона (все условия) | 0,272 |

| Оценка | УНС | Спецификации отрасли |

| 17-4 Дуплексная нержавеющая сталь | УНС 17-4ФН | UNS: S17400 |

| • АМС: 5604 | ||

| • ASTM: A693 | ||

| • ASME: SA693 | ||

| • W. Nr./EN: 1.4548 | ||

| УНС 630 | UNS: S17400 | |

| • АМС: 5604 | ||

| • ASTM: A693 | ||

| • ASME: SA693 | ||

| • W. Nr./EN: 1.4548 |

| Нержавеющая сталь 17-4PH/630 Светлый брусок | SS 17-4PH/630 Светлая полоса |

| 17-4PH/630 SS Светлая полоса | |

| Нержавеющая сталь 17-4PH/630 Светлый брусок | |

| UNS S17-4PH/63000 SS Светлая полоса | |

| ВЕРКСТОФФ Н.Р. 1.4548 Яркая полоса | |

| ASTM A276 17-4PH/630 нержавеющая сталь блестящий пруток | |

| Шестигранный стержень из нержавеющей стали 17-4PH/630 | Шестигранный стержень SS 17-4PH/630 |

| Шестигранный пруток 17-4PH/630 SS | |

| Шестигранный стержень из нержавеющей стали 17-4PH/630 | |

| UNS S17-4PH/63000 Шестигранный стержень из нержавеющей стали | |

| Шестигранный стержень из нержавеющей стали ASTM A276 17-4PH/630 | |

| Квадратный пруток из нержавеющей стали 17-4PH/630 | SS 17-4PH/630 квадратный пруток |

| 17-4PH/630 квадратные прутки из нержавеющей стали | |

| 17-4PH/630 квадратный пруток из нержавеющей стали | |

| UNS S17-4PH/63000 квадратный пруток из нержавеющей стали | |

| ВЕРКСТОФФ Н.Р. 1,4548 Квадратный стержень | |

| Квадратные прутки из нержавеющей стали ASTM A479 17-4PH/630 | |

| Прямоугольный пруток из нержавеющей стали 17-4PH/630 | Прямоугольный пруток SS 17-4PH/630 |

| Прямоугольные прутки 17-4PH/630 SS | |

| 17-4PH/630 Прямоугольный пруток из нержавеющей стали | |

| Прямоугольные прутки из нержавеющей стали UNS S17-4PH/63000 | |

| ВЕРКСТОФФ Н.Р. 1.4548 Прямоугольный стержень | |

| Прямоугольный пруток из нержавеющей стали ASTM A276 17-4PH/630 | |

| Плоские прутки из нержавеющей стали 17-4PH/630 | SS 17-4PH/630 плоский пруток |

| 17-4PH/630 SS плоские прутки | |

| Плоские прутки из нержавеющей стали 17-4PH/630 | |

| Плоские прутки из нержавеющей стали UNS S17-4PH/63000 | |

| ВЕРКСТОФФ Н.Р. 1.4548 Плоские стержни | |

| ASTM A276 17-4PH/630 плоские прутки из нержавеющей стали | |

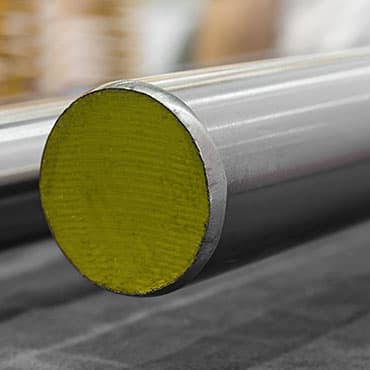

| Полированный брусок из нержавеющей стали 17-4PH/630 | SS 17-4PH/630 Полированный брусок |

| 17-4PH/630 SS полированные прутки | |

| 17-4PH/630 Полированный пруток из нержавеющей стали | |

| Полированные прутки из нержавеющей стали UNS S17-4PH/63000 | |

| ВЕРКСТОФФ Н.Р. 1.4548 Полированный стержень | |

| Полированный пруток из нержавеющей стали ASTM A476 17-4PH/630 | |

| Резьбовой стержень из нержавеющей стали 17-4PH/630 | Резьбовой стержень SS 17-4PH/630 |

| Резьбовые стержни 17-4PH/630 SS | |

| Резьбовой стержень из нержавеющей стали 17-4PH/630 | |

| Резьбовой стержень из нержавеющей стали UNS S17-4PH/63000 | |

| ВЕРКСТОФФ Н.Р. 1.4548 Резьбовой стержень | |

| Резьбовой стержень из нержавеющей стали ASTM A276 17-4PH/630 |

Выбирайте Daxun и сделайте своих клиентов довольными.

Быстрый ответ-17-4 Стержень из нержавеющей стали

Daxun предоставляет клиентам своевременную и быструю доставку изделий из прутка из нержавеющей стали 17-4. За скоростью стоит системная поддержка от информационного потока до логистики и движения капитала. Например, с точки зрения информационного потока данные о заказах Daxun передаются в логистическую систему в режиме реального времени, и данные бесшовно связаны; с точки зрения логистики центр обработки находится недалеко от портов, рек и морей, с разумным планированием, быстрым реагированием, складскими и транспортными связями и эффективной загрузкой, что гарантирует выполнение задачи в срок.

Преимущества Даксуна

- Разновидности: Мы предлагаем широкий ассортимент размеров и марок, включая серии 300, 400, 600 и другие.

- Гибкость: независимо от того, нужны ли вам горячекатаные или холоднотянутые прутки, длина наших прутков из нержавеющей стали подбирается в соответствии с требованиями вашего конкретного проекта.

- Стандарты качества: стержень из нержавеющей стали 17-4 соответствует строгим стандартам ASTM, ISO9001, GB, NSF/ANSI, что гарантирует надежность и производительность.

- Индивидуальные заказы: Ищете специальные размеры прутков из нержавеющей стали? Мы предлагаем различные варианты изготовления прутков из нержавеющей стали по конкурентоспособным ценам и с удобным онлайн-заказом.

Упаковка стержня из нержавеющей стали 17-4

Мы уделяем внимание каждому процессу, чтобы гарантировать качество, упаковка круглой стали 17-4, которую мы обычно принимаем, заключается в упаковке круглых прутков из нержавеющей стали в экологически чистые пластиковые пакеты, а затем в деревянные ящики или деревянные поддоны без фумигации. Также можно обсудить индивидуальную упаковку, такую как OEM. Мы предоставляем почти все, чтобы удовлетворить ваши требования к упаковке круглых прутков. Мы придаем большое значение упаковке. Круглые прутки упаковываются в деревянные гофрированные коробки, а снаружи обертываются пластиковой упаковкой и пузырчатой пленкой.

Качество, доставка, проверка

- Daxun также проводит несколько испытаний на обеспечение качества. Эти испытания включают испытание на сплющивание, испытание на питтинг и сопротивление, механическое испытание, испытание на твердость, положительную идентификацию материала, испытание на расширение и т. д. Все эти испытания гарантируют, что материал подходит для требуемого применения.

- В процессе производства мы измеряем диаметр, толщину и поверхность изделия. Наш стандартный срок поставки составляет 7-15 дней, за исключением некоторых изделий специального размера, срок поставки увеличивается до 20 дней.

Срок поставки строго соответствует договору. - Поддержка сторонних агентств-клиентов при посещении завода для проведения инспекции

- Предоставляем бесплатные образцы клиентам для тестирования

- Поддержка инспекции завода на месте или видеоинспекции

Техническая поддержка

Если вам нужна дополнительная техническая помощь, наш местный металлург и знающий персонал будут рады помочь. Кроме того, Daxun может похвастаться сертифицированной испытательной лабораторией — первой в отрасли многометаллического и пластикового инвентаря. Это, по нашему мнению, демонстрирует нашу непоколебимую преданность качеству и нашу философию как поставщика полного спектра услуг.

Информация для заказа стержня из нержавеющей стали 17-4

17-4 нержавеющий пруток Заказ на закупку должен включать количество, класс PSL, тип или категорию, ссылку API5L, диаметр, отделку, длину и любые применимые приложения или дополнительные требования, касающиеся химического состава, механических свойств, термической обработки, дополнительных испытаний, производственного процесса, отделки поверхности или отделки концов. Прутки подвергаются светлому отжигу на твердый раствор.

Характеристики стержня из нержавеющей стали 17-4PH/630

Daxun Alloy Позвольте вашему бренду быстро улучшиться

- Галерея

- Состояние доставки

- Возрастная закалка

| Выбор штата доставки | Состояние поверхности |

| Кованый | Черный |

| Полированный | |

| Горячекатаный | Черный |

| Полированный | |

| Яркий | |

| Маринованный | |

| Холоднотянутый | Полированный |

| Яркий | |

| Примечание: | |

| 1. Если вам требуется другой штат доставки, чем указанный выше, пожалуйста, уточните у нас. | |

| 2. В случае возникновения каких-либо вопросов или заказов, пожалуйста, сообщите нам о любых дополнительных требованиях, не указанных здесь. | |

| Материал в состоянии, подвергнутом отжигу на твердый раствор, может быть подвергнут старению следующим образом: *Обозначает двойное старение | ||||||||||||

| Состояние | Н900 (Н480) | Н925 (Н495) | Н1025 (Н550) | Н1075 (Н580) | Н1100 (Н595) | Н1150 (Н620) | Н1150М (Н620М)* | Плюс | H1150D (H620D)* | Плюс | ||

| Нагреть до | ±15oF | 900oF | 925 градус по Фаренгейту | 1025oF | 1075oF | 1100oF | 1150oF | 1400oF | 1150oF | 1150oF | 1150oF | |

| ±9oC | 480оС | 495oC | 550oC | 580oC | 595oC | 620oC | 760oC | 620oC | 620oC | 620oC | ||

| Удерживать в течение нескольких часов | 1 | 4 | 4 | 4 | 4 | 4 | 2 | 4 | 4 | 4 | ||

| Охлаждение до температуры ниже | Воздух | Воздух | Воздух | Воздух | Воздух | Воздух | Воздух | Воздух | Воздух | Воздух | ||

| 90oF (32oC) | ||||||||||||

Типы стержней из нержавеющей стали 17-4PH/630 (6)

Информация доступна для ознакомления и скачивания

Производство прутков из нержавеющей стали

Daxun — надежный производитель прутков и стержней из нержавеющей стали.

Как профессиональный производитель, Daxun гарантирует, что вся производимая нами продукция отличается высоким качеством. Поэтому мы гарантируем, что все нержавеющие прутки сертифицированы по стандартам ISO9001, SGS, CE, OQC

Последние горячие проекты и продукты

Related Products (12)

Ведущие поставщики прутков и стержней из нержавеющей стали в Китае

КОРРОЗИОННАЯ УСТОЙЧИВОСТЬ:

- Выдерживает коррозионное воздействие лучше, чем любая из стандартных закаливаемых нержавеющих сталей.

- Сравним со сплавом 304 в большинстве сред.

- Устойчив к коррозии в некоторых отраслях химической, нефтяной, молочной и пищевой промышленности.

- Подвержен образованию трещин и выбоин при воздействии стоячей морской воды в течение длительного времени.

СВАРОЧНОСТЬ:

- Успешно сваривается большинством распространенных методов сварки плавлением и сопротивлением.

- Не допускается соединение методом кислородно-ацетиленовой сварки.

- Как правило, предварительный нагрев не требуется.

- Температура между проходами должна быть ограничена 248°F.

- После полной термической обработки сварной шов приобретает лучшую прочность.

ИСПОЛЬЗОВАНИЕ ПРИ ПОВЫШЕННОЙ ТЕМПЕРАТУРЕ:

- Отличная стойкость к окислению до температуры около 1100°F.

- Длительное воздействие повышенной температуры может привести к снижению прочности в условиях дисперсионного твердения.

ОБРАБОТКА – ГОРЯЧАЯ ФОРМОВКА:

- Для ковки равномерно нагрейте до 2150/2200°F и выдерживайте полчаса на каждый дюйм.

- Предпочтительный температурный диапазон для горячей штамповки составляет 650–900 °F, пока сталь остается аустенитной.

- Чтобы обеспечить наилучшие условия для закалки, поковки необходимо повторно закалить при температуре 1875–1925 °F.

- Охладите поковки до температуры ниже 90°F, чтобы обеспечить измельчение зерна.

ОБРАБОТКА – ХОЛОДНАЯ ФОРМОВКА:

- Сплав 17-4 предназначен только для мягких условий эксплуатации, поскольку в отожженном (обработанном на твердый раствор) состоянии материал твердый.

- Для тяжелой холодной обработки материал следует подвергнуть термической обработке до состояния H1150. Это поможет предотвратить возможное растрескивание.

- Часто требуется радиус изгиба более 7T.

- Для повышения стойкости к коррозии под напряжением после холодной штамповки рекомендуется повторное старение при температуре дисперсионного твердения.

ОБРАБАТЫВАЕМОСТЬ:

- Может подвергаться механической обработке как в условиях обработки на твердый раствор, так и в условиях дисперсионного твердения.

Механические свойства

- Нержавеющая сталь типа 17-4PH обладает превосходными механическими свойствами. Для применений, требующих высокой прочности и твердости, а также коррозионной стойкости, нержавеющая сталь типа 17-4PH является выдающимся выбором, и она более экономична, чем многие цветные сплавы с высоким содержанием никеля.

Круглые прутки из нержавеющей стали марки 17-4ph/630

Круглые прутки из нержавеющей стали 17-4ph широко используются. Они широко используются в различных областях от строительства до автомобильных деталей. Благодаря широкому спектру применения Daxun Alloys предлагает круглые прутки из нержавеющей стали различных марок и размеров. Благодаря нашему бесплатному расширенному сервису резки мы можем точно удовлетворить ваши требования каждый раз.

Широкий выбор размеров

Круглые прутки из нержавеющей стали 17-4ph можно легко заказать в широком диапазоне размеров. Просто выберите марку стали, которая вам нужна, и мы предоставим прутки длиной от 500 мм до 6 метров и диаметром от 3 мм до 500 мм. Мы даже даем вам возможность заказа в метрических или имперских размерах.

Если вам нужно что-то нестандартного размера, это не проблема. Мы предлагаем неограниченное количество бесплатных отрезов по длине. Используя самые современные ленточные пилы для обеспечения точности и повторяемости, мы можем точно соответствовать вашим требованиям каждый раз. Просто дайте нам знать при заказе.

Свяжитесь с вашим поставщиком круглого прутка из нержавеющей стали

Независимо от того, ищете ли вы разовый заказ или долгосрочный план пополнения запасов, мы предлагаем различные сорта круглого прутка из нержавеющей стали для удовлетворения ваших потребностей! Усильте свой производственный процесс с помощью высококачественного круглого прутка из нержавеющей стали от Daxun Alloy. Свяжитесь с нами сегодня, чтобы адаптировать превосходные решения по металлу под ваши конкретные потребности!

Заказать круглые прутки из нержавеющей стали просто. Наш сайт предлагает простой пошаговый процесс. Кроме того, вы можете позвонить в нашу службу продаж по телефону +8613382898899. Если у вас есть какие-либо вопросы, отправьте нам электронное письмо по адресу [email protected], и наша команда свяжется с вами как можно скорее.

Мы можем предоставить образцы стержней из нержавеющей стали 17-4 для проверки качества. Образец бесплатный, вы платите только за доставку.

Мы экспортируем продукцию в более чем 42 страны, такие как Канада, Чили, Кувейт, Германия, Южная Корея, Саудовская Аравия, Сингапур и т. д.

Минимальный заказ составляет 1 тонну прутка из нержавеющей стали 17-4.

Пробные заказы могут быть доставлены в течение недели. Для обычных заказов это занимает около двух недель.