Поставщик пластин из нержавеющей стали AISI 904L

Являясь ведущим поставщиком и экспортером листовой нержавеющей стали в Китае, компания Daxun поставляет листы из нержавеющей стали марки 904L по всему миру.

- Марка: AISI 904L-N08904-03Х20Н25М7БР

- Особенности: Супер коррозионная стойкость

- Производство: холоднокатаный лист, горячекатаный лист, кованый лист

- Стандарты: GOST ASTM, ASME, GB, DIN, JIS, ISO, EN, BS.

- Тип: Холоднокатаный тонкий лист, горячекатаный толстый лист

- Поверхность: 2B, NO.1, NO.4, HL, BA, 8K и т.д.

- Длина: 2438 мм3048 мм6000 мм можно настроить

- Происхождение: TISCO, Baosteel, Posco, Tsingshan, Delong, ATI,

Обзор нержавеющей стали AISI 904L

Сплав AISI 904L — это супераустенитная нержавеющая сталь, разработанная для умеренной и высокой коррозионной стойкости в различных технологических средах. Этот высоколегированный аустенитный продукт предназначен для использования в условиях сильной коррозии, что делает его надежным выбором для сложных применений. Высокое содержание хрома и никеля, а также добавки молибдена и меди обеспечивают превосходную коррозионную стойкость. Благодаря высоколегированному химическому составу, включающему 25% никеля и 4,5% молибдена, сплав AISI 904L хорошо подходит для применений, требующих как высокой коррозионной стойкости, так и высокой прочности. Этот уникальный состав позволяет ему выдерживать среды, включающие разбавленную серную кислоту, горячую фосфорную кислоту и другие неорганические кислоты, обеспечивая длительную работу в суровых условиях.

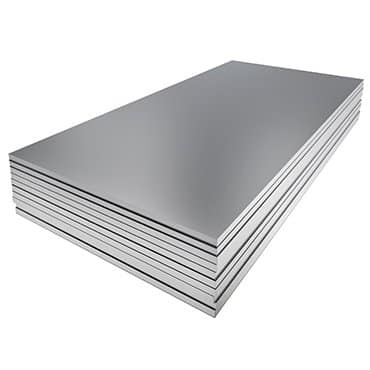

Габариты и размеры

Лист нержавеющей стали Alloy 904L доступен в различных размерах и габаритах для удовлетворения конкретных требований применения. Доступная толщина для Alloy AISI 904L варьируется от 3/16” до 2”, что обеспечивает гибкость для различных промышленных нужд. Лист UNS N08904 может иметь толщину до 8 мм, в то время как пластина 904L обычно толще 8 мм и может иметь толщину до 75 мм. Эти размеры могут быть настроены в соответствии с конкретными отраслевыми стандартами и спецификациями, гарантируя, что материал идеально впишется в любой проект. Кроме того, лист нержавеющей стали 904L можно легко сваривать и обрабатывать с использованием стандартных методов изготовления в цеху, что упрощает производственный процесс и обеспечивает высококачественные результаты.

Технические данные

- Параметр

- Химический состав

- Механические свойства

- ФИЗИЧЕСКИЕ СВОЙСТВА

- Стандарт

| Плиты, листы и полосы из нержавеющей стали AISI 904L | ГОСТ 5582-75, ГОСТ 7350-77, ГОСТ 19904-90, ГОСТ 5632-72 ASTM B 168/ASME SB 168, ASTM B 906/ASME SB 906, случаи кода ASME 1827 и N-253, SAE/AMS 5540, BS 3072NA14 и 3073NA14, DIN 17750, ISO 6208, EN 10095, MIL-DTL-23228. |

| Стандартные размеры пластин и листов из нержавеющей стали 904L | 1000 x 2000 мм, 1220 x 2440 мм, 1500 x 3000 мм, 2000 x 2000 мм, 2000 x 4000 мм |

| Холоднокатаный стальной лист 904L 0,5-6,4 мм | |

| Горячекатаный стальной лист 904L 3,0–10,0 мм | |

| Твердость пластины SS 904L | Поставщики листов из мягкой, твердой, полутвердой, четвертьтвердой и пружинно-твердой нержавеющей стали 904L |

| Наличие размеров фольги из нержавеющей стали 904L | Толщина: 8–100 микрон (0,00031–0,004 дюйма) |

| Ширина: до 500 мм (19,5 дюймов) | |

| Вес (в рулонах): до 50 кг (110 фунтов); например, приблизительно 1400 м при 8 мкм и приблизительно 112 м при 100 мкм. | |

| Профилирование | Для предоставления полного спектра услуг по профилированию в Китае мы используем многочисленные методы профилирования, в том числе: |

| Лазерная резка пластин | |

| Плазменная резка листового металла | |

| Резка кислородно-пропановым пламенем | |

| Допуски ширины и толщины | EN 10258 (ранее DIN 59381) |

| Лента из нержавеющей стали EN 10151 904L для пружин | |

| Полоса из нержавеющей стали 904L EN 10088 (общая) | |

| Стандарты и разрешения на пластины из нержавеющей стали 904L | EN ISO 18286 |

| EN 10051 | |

| EN 10088-1 | |

| ИСО 15510 | |

| EN ISO 9445 | |

| ASTM А 480 | |

| ASTM А 959 | |

| ASME-IID | |

| Профили плазмы | По чертежам заказчика |

| Услуги с добавленной стоимостью для пластин из нержавеющей стали 904L | Лазерная резка, гидроабразивная резка, плазменная резка, гибка и механическая обработка, подготовка кромок, сварка, распиловка и резка. |

| Услуги с добавленной стоимостью для рулонов нержавеющей стали 904L | Нарезка по длине |

| Продольная резка | |

| Полировка | |

| Бланкирование | |

| SS 904L Плита Происхождение | Происхождение: Китай, Европейское происхождение, Японское происхождение |

| Упаковка стального листа 904L | Связки с водонепроницаемой тканью снаружи или фанерный ящик |

| Тест | Тестирование UT, SGS, TUV и т.д. |

| Элемент | % Присутствует (в форме продукта) |

| Углерод (С) | 0,02 |

| Кремний (Si) | 0,7 |

| Марганец (Mn) | 2 |

| Фосфор (P) | 0,03 |

| Сера (S) | 0.01 |

| Хром (Cr) | 19.00 – 21.00 |

| Никель (Ni) | 24.00 – 26.00 |

| Азот (N) | 0,15 |

| Молибден (Mo) | 4.00 – 5.00 |

| Медь (Cu) | 1.20 – 2.00 |

| Железо (Fe) | Баланс |

| Форма продукта | ||||||||

| С | ЧАС | П | Л | Л | ТВ/ТС | |||

| Толщина (мм) Макс. | 8 | 13.5 | 75 | 160 | 250 2) | 60 | ||

| Предел текучести | R p0,2 ·Н/мм 2 | 240 3) | 220 3) | 220 3) | 230 4) | 230 5) | 230 6) | |

| R p1,0 ·Н/мм 2 | 270 3) | 260 3) | 260 3) | 260 3) | 260 3) | 250 3) | ||

| Предел прочности | R м ·ОН/мм 2 | 530 – 730 3) | 530 – 730 3) | 520 – 720 3) | 530 – 730 4) | 530 – 730 5) | 520 – 720 6) | |

| Удлинение мин. в % | Дж мин聽(Продольный) | – | 100 | 100 | 100 | – | 120 | |

| Дж мин聽(поперечный) | – | 60 | 60 | – | 60 | 90 | ||

| Плотность при 20°C кг/м3 | 8 | |

| Теплопроводность Вт/м К при | 20°С | 12 |

| Модуль упругости кН/мм2 при | 20°С | 195 |

| 200°С | 182 | |

| 400°С | 166 | |

| 500°С | 158 | |

| Удельная теплоемкость при 20°СДж/кг К | 450 | |

| Удельное электрическое сопротивление при 20°C Ом мм2/м | 1 | |

| УНС AISI 904L | 1.4539 | УНС N08904 |

| ASTM A240 | ASTM A240 | ASTM A240 |

| ASTM A480 | ASTM A480 | ASTM A480 |

| ASME SA240 | ASME SA240 | ASME SA240 |

| АМС 5521 | АМС 5521 | АМС 5521 |

Выбирайте Daxun и сделайте своих клиентов довольными.

Быстрая доставка

Мы обеспечиваем быструю и своевременную поставку листа из нержавеющей стали 904L для клиентов с неотложными потребностями. За высокой скоростью стоит отлаженная система: заказы Daxun мгновенно передаются в логистическую систему, обеспечивая беспрерывную обработку. Наш склад расположен рядом с автомагистралями и морскими портами, что гарантирует быструю отгрузку, эффективную логистику и соблюдение сроков.

Нержавеющая сталь 904L — идеальный выбор при срочных поставках.

Характеристики пластины 904L

Тип 904L — высоколегированная аустенитная нержавеющая сталь, известная своими коррозионными свойствами.

- Немагнитный

- Более сильные коррозионные свойства, чем у типов 316L и 317L

- Хорошая устойчивость к серной, фосфорной и уксусной кислотам

- Высокая стойкость к щелевому и коррозионному растрескиванию под напряжением

- Отличная формуемость и свариваемость

Применение нержавеющей стали 904L

Применение нержавеющей стали марки 904L:

- Охлаждающее оборудование для морской воды

- Химическая переработка серной, фосфорной и уксусной кислот

- Теплообменники

- Конденсаторные трубки

- Газовая мойка

- Контрольно-измерительные приборы и приборы

- Нефтегазовая промышленность

- Фармацевтическое производство

- Электропроводка в электрофильтрах

Качество, доставка, проверка

-

Daxun Alloy стремится к обеспечению качества. Компания проводит различные испытания, чтобы убедиться в пригодности материалов. Эти испытания включают испытания на сплющивание, испытания на питтинг и испытания на растяжение. Кроме того, компания также проводит испытания на механические свойства, твердость и расширение. Положительная идентификация материалов является еще одним ключевым показателем обеспечения качества. Все эти испытания гарантируют, что материал соответствует требованиям применения. Клиенты могут доверять Daxun Alloy в предоставлении высококачественной, подходящей продукции.

Технические услуги

Если вам нужна дополнительная техническая помощь, наш местный металлург и знающий персонал будут рады помочь. Кроме того, Daxun может похвастаться сертифицированной испытательной лабораторией — первой в отрасли многометаллического и пластикового инвентаря. Это, по нашему мнению, демонстрирует нашу непоколебимую преданность качеству и нашу философию как поставщика полного спектра услуг.

Расширенная обработка

Качество — наша вера, честность — наш принцип. полная прослеживаемость продукции. контроль происхождения и качества. Мы боремся с подделками, предоставляем решения по выбору материалов, контролируемые на каждом этапе от заказа до послепродажного обслуживания. Лист из нержавеющей стали 904L от Daxun — это точность, надежность и проверенное качество.

Характеристики пластины из нержавеющей стали 904L

Daxun Позвольте вашему бренду быстро улучшиться

- Галерея

- Терпимость

- Состояние доставки

- Другие серии продуктов

| Допуск для листа 2B | |||

| Размер | Рейтинг толерантности | ||

| Группа 1 | Группа 2 | Группа 3 | |

| 0,4 | 0,3 ~ 0,32 | 0,33 ~ 0,37 | 0,37 ~ 0,39 |

| 0,5 | 0,4 ~ 0,42 | 0,43 ~ 0,47 | 0,47 ~ 0,49 |

| 0,6 | 0,5 ~ 0,52 | 0,53 ~ 0,56 | 0,57 ~ 0,59 |

| 0,7 | 0,6 ~ 0,62 | 0,63 ~ 0,67 | 0,67 ~ 0,69 |

| 0,8 | 0,7 ~ 0,72 | 0,73 ~ 0,77 | 0,74 ~ 0,79 |

| 0.9 | 0,8 ~ 0,82 | 0,83 ~ 0,87 | 0,87 ~ 0,89 |

| 1 | 0,89 ~ 0,9 | 0,91 ~ 0,94 | 0,94 ~ 0,99 |

| 1.2 | 1,02 ~ 1,08 | 1,09 ~ 1,15 | 1,16 ~ 1,18 |

| 1.5 | 1,32 ~ 1,38 | 1,39 ~ 1,45 | 1,46 ~ 1,48 |

| 2 | 1,72 ~ 1,79 | 1,8 ~ 1,86 | 1,87 ~ 1,9 |

| 2.5 | 2,23 ~ 2,36 | 2,32 ~ 2,42 | 1,42 ~ 1,47 |

| 3 | 2,7 ~ 2,77 | 2,78 ~ 2,82 | 2,85 ~ 2,9 |

| Допуск для горячекатаного листа №1 | |||

| Размер | Рейтинг толерантности | ||

| Группа 1 | Группа 2 | Группа 3 | |

| 3 | 2,6 ~ 2,75 | 2,75 ~ 2,85 | 2,86 ~ 2,9 |

| 4 | 3,5 ~ 3,6 | 3,6 ~ 3,75 | 3,76 ~ 3,95 |

| 5 | 4,5 ~ 4,6 | 4,6 ~ 4,75 | 4,75 ~ 4,95 |

| 6 | 5.4 ~ 5.6 | 5,6 ~ 5,75 | 5,75 ~ 5,85 |

| 8 | 7.3 ~ 7.5 | 7,5 ~ 7,65 | 7,65 ~ 7,85 |

| 10 | 9.2 ~ 9.3 | 9.3 ~ 9.6 | 9,6 ~ 9,85 |

| 12 | 11.1 ~ 11.2 | 11.2 ~ 11.6 | 11,6 ~ 11,85 |

| 14 | 13.1 ~ 13.2 | 13.2 ~ 13.6 | 13,6 ~ 13,85 |

| 16 | 15.2~ 15.5 | 15.5~ 15.7 | 15.7~ 16.1 |

| 18 | 17.2~ 17.5 | 17.5~ 17.7 | 17.7~ 18.1 |

| 20 | 19.2~ 19.5 | 19.5~ 19.7 | 19.7~ 20.1 |

| 30 | 29.2~ 29.5 | 29,5~ 29,7 | 29.7-30.1 |

| 40 | 39,2~ 39,5 | 39,5~39,7 | 39,7~ 40,1 |

| 50 | 49,2~ 49,5 | 49,5~ 49,7 | 49,7~ 50,1 |

| 60 | 59.2~ 59.5 | 59,5~ 59,7 | 59,7~ 60,1 |

| Выбор штата доставки | Состояние поверхности |

| Холоднокатаный | 2Б |

| 2D | |

| БА | |

| Линия роста волос | |

| №3 | |

| №4 | |

| 6К | |

| 8К | |

| Примечание: | |

| 1. Если вам требуется другой штат доставки, чем указанный выше, пожалуйста, согласуйте это с нами. | |

| 2. В случае возникновения каких-либо вопросов или заказов, пожалуйста, сообщите нам о любых дополнительных требованиях, не указанных здесь. | |

| Состояние доставки | |

| Выбор штата доставки | Состояние поверхности |

| Горячекатаный | №1 |

| №3 | |

| №4 | |

| 6К | |

| 8К | |

| Маринованный | |

| Примечание: | |

| 1. Если вам требуется другой штат доставки, чем указанный выше, пожалуйста, согласуйте это с нами. | |

| 2. В случае возникновения каких-либо вопросов или заказов, пожалуйста, сообщите нам о любых дополнительных требованиях, не указанных здесь. | |

| Оценка | Тип | Толщина | Поверхность |

| аустенитный | 304/304H/304L/304J1 | 0,25-150 мм | 2Б/БА/№4/8К/СБ/ХЛ/№1 |

| 321 | 0,4-80 мм | 2Б/БА/№4/8К/СБ/ХЛ/№1 | |

| 316/316L/317L/316Ti | 0,3-80 мм | 2Б/БА/№4/8К/СБ/ХЛ/№1 | |

| Феррит | 430 | 0,4-3,0 мм | 2Б/БА/№4/8К/СБ/ХЛ |

| Сверхчистый феррит | 443 | 0,4-2,0 мм | 2Б |

| 436Л/439/444/441 | 0,5-3,0 мм | 2Б、2Д | |

| 409л | 0,4-2,5 мм | 2Б、2Д | |

| Оценка | Тип | Толщина | Оригинал |

| Жаропрочная сталь | 309С | 0,5-40 мм | ЧН |

| 310С | 0,5-40 мм | ЧН | |

| Дуплексная сталь | 2101 | 1,5-50 мм | ЧН |

| 2304 | 3,0-50 мм | ЧН | |

| 2205 | 0,5-60 мм | ЧН | |

| 2507 | 1,0-60 мм | Швеция / Япония / Китай | |

| Супер аустенитная сталь | N08904 | 0,6-50 мм | Швеция / Япония / Китай |

| S31254 | 0,5-50 мм | Швеция / Япония / Китай | |

| N08926 | 0,5-50 мм | Швеция / Япония / Китай | |

| N08367 | 0,5-50 мм | Швеция / Япония / Китай | |

| Сплав на основе никеля | N08031 | 1,0-50 мм | США / Япония / Германия |

| N08810/N08800 | 0,8-50 мм | США / Япония / Китай | |

| N08028 | 1,0-20 мм | США / Германия / Япония | |

| N08020 | 1,0-20 мм | США / Германия / Япония | |

| N08825 | 0,8-40 мм | США / Германия / Швеция / Япония / Китай | |

| N10276 | 0,5-50 мм | США / Германия / Япония | |

| N06022 | 1,0-50 мм | США / Германия / Япония | |

| N06625 | 0,8-20 мм | США / Германия / Китай | |

| N04400 | 1,0-20 мм | США / Германия / Япония | |

| N06600 | 1,0-50 мм | США / Германия / Япония / Китай | |

| N02201 | 0,5-20 мм | США/Япония | |

| Титан | ТА1/Гр1 | 0,5-50 мм | Япония / Китай |

| ТА2/Гр2 | 0,5-50 мм | Япония / Китай | |

| Сварочный материал | ERNiCrMo-13 | 1.2、2.4мм | ГЕР |

| ЭРНиКрМо-3 | 2.4мм | ГЕР | |

| ЭРНиКрМо-4 | 2.4мм | НАС |

Поверхность и форма пластины из нержавеющей стали 904L (7)

Информация доступна для ознакомления и скачивания

Daxun — надежный производитель пластин из нержавеющей стали.

Как профессиональный производитель, Daxun гарантирует, что вся производимая нами продукция отличается высоким качеством. Поэтому мы гарантируем, что все пластины из нержавеющей стали сертифицированы по стандартам ISO9001, SGS, CE, OQC

Последние горячие проекты и продукты

Сопутствующие товары (13)

Ведущие поставщики листов из нержавеющей стали в Китае

Стандарты и спецификации :

-

Листовая нержавеющая сталь Alloy 904L регулируется рядом стандартов и спецификаций, которые гарантируют ее качество и производительность. Ключевые стандарты включают ASTM A240 и ASME SA240, которые определяют требования к химическому составу, механическим свойствам и размерам материала. Кроме того, листовая нержавеющая сталь 904L соответствует критериям, установленным EN 10095, ISO 6208 и DIN 17750, среди прочих. Эти стандарты гарантируют, что материал соответствует строгим контролям качества, что делает его пригодным для различных требовательных применений. Соответствуя этим стандартам, листовая нержавеющая сталь 904L обеспечивает надежность и постоянство производительности в различных отраслях промышленности.

Нержавеющая сталь марки 904L:

- Аустенитная нержавеющая сталь марки 904L — это нестабилизированная, высоколегированная, низкоуглеродистая сталь. Эта марка теперь значительно более устойчива к сильным восстанавливающим кислотам, особенно серной кислоте, из-за включения меди. Медь добавляется в некоторые марки нержавеющей стали. Это добавление развивает устойчивость к серной кислоте и другим восстановителям. Медьсодержащие марки работают лучше как в агрессивных, так и в мягких условиях. Они обладают повышенной прочностью и длительной производительностью. Daxun Alloy тщательно выбирает эти марки для конкретных применений. Клиенты могут быть уверены, что эти материалы выдержат сложные условия.

- Эта марка обладает исключительной формуемостью и свариваемостью и немагнитна при любых обстоятельствах. Эта марка обладает исключительной прочностью даже при криогенных температурах благодаря своей аустенитной структуре. Эта марка стали известна своими превосходными характеристиками в суровых условиях.

- Никель и молибден, два очень дорогих элемента, присутствуют в 904L в довольно больших количествах. Дуплексная нержавеющая сталь 2205 (S31803 или S32205) теперь может использоваться во многих областях, где эта марка исторически хорошо себя зарекомендовала при более низкой стоимости, поэтому 904L используется реже, чем раньше.

Коррозионная стойкость:

- Его превосходная устойчивость к различным условиям является дополнением к его изначальной устойчивости к серной кислоте. Теплая морская вода и другие условия с высоким содержанием хлоридов являются хорошей устойчивостью для материала, о чем свидетельствует PRE 35. По сравнению с типичными аустенитными марками, высокая концентрация никеля обеспечивает значительно более высокую устойчивость к коррозионному растрескиванию под напряжением. Серная и другие восстанавливающие кислоты более устойчивы к меди, особенно в чрезвычайно агрессивном диапазоне «средней концентрации».

- Коррозионные свойства стали 904L в целом занимают промежуточное положение между показателями обычной аустенитной марки 316L и высоколегированных «супераустенитных» марок с содержанием молибдена 6% и эквивалентным содержанием.

- По сравнению с такими марками, как 304L и 310L, не содержащими молибден, 904L менее устойчива к сильной азотной кислоте.

- После холодной обработки сталь следует подвергнуть обработке на твердый раствор для обеспечения оптимальной стойкости к коррозионному растрескиванию под напряжением в сложных условиях.

Теплостойкость:

- Высокая стойкость к окислению, но при более высоких температурах страдает от структурной нестабильности (выделение хрупких фаз, таких как сигма), как и другие высоколегированные марки. Не рекомендуется использовать при температуре выше 550°C. Код ASME по котлам и сосудам под давлением устанавливает расчетные значения напряжений для 904L на уровне 371°C.

Термическая обработка:

- Обработка на твердый раствор (отжиг)Нагревание до 1090-1175°C и быстрое охлаждение. Этот сорт не может быть упрочнен термической обработкой

Сварка:

- Можно успешно сваривать 904L, используя все обычные методы. Из-за его полностью аустенитной кристаллизации эта марка склонна к образованию термических трещин, особенно в ограниченных сварных соединениях, поэтому следует соблюдать осторожность. Лучше не использовать предварительный нагрев, и послесварочная термообработка, как правило, также не требуется. Стержни и электроды марки 904L предварительно аттестованы AS 1554.6 для сварки 904L.

Изготовление:

- Поскольку это сорт высокой чистоты и низкого содержания серы, 904L не будет обрабатываться так же хорошо, как другие сорта, специально разработанные для обработки. Тем не менее, сорт 904L можно обрабатывать обычными методами. Достичь небольшого радиуса изгиба легко. В большинстве случаев это делается в холодном состоянии. Хотя это следует учитывать, если изготовление будет использоваться в месте, где ожидаются условия сильного коррозионного растрескивания под напряжением, последующий отжиг обычно не требуется.

Типичные области применения:

- Перерабатывающая установка для серной, фосфорной и уксусной кислот. Переработка целлюлозы и бумаги. Компоненты в газоочистных установках. Оборудование для охлаждения морской водой. Компоненты нефтеперерабатывающих заводов. Провода в электрофильтрах.

Указанные свойства:

- Согласно ASTM A240M, эти характеристики требуются для плоского проката (пластины, листы и рулоны). Другие товары, такие как трубы, трубки и прутки, имеют схожие, хотя и не всегда одинаковые, качества, указанные в их индивидуальных спецификациях.

Листы из нержавеющей стали марки 904L с различными вариантами отделки

Daxun Alloy предлагает широкий ассортимент листов из нержавеющей стали. Эти листы поставляются с различными красивыми покрытиями. Клиенты могут выбрать матовое, гладкое 2B или зеркальное 8K покрытие. Каждый лист имеет защитную пленку на готовой стороне. Эта пленка легко снимается после изготовления или установки. Она защищает поверхность от износа и следов. Обратная сторона листа необработанная.

Листовая нержавеющая сталь марки 904L является наиболее часто используемым сортом. Она легко сваривается, формуется и имеет хорошую коррозионную стойкость.

Мы можем оказать помощь в поставке листов из нержавеющей стали любого необходимого размера.

Листы из нержавеющей стали Daxun Alloy отвечают особым требованиям. Они доступны в трех вариантах отделки и различных размерах. Компания предлагает бесплатную неограниченную услугу резки. Это позволяет клиентам получить любой необходимый им индивидуальный размер. Daxun Alloy стремится соответствовать уникальным спецификациям клиентов. Разнообразные варианты гарантируют идеальное соответствие любому проекту.

Мы можем удовлетворить любые потребности в размерах толщиной от 0,3 до 30 мм и размером от 50 x 50 мм до 2500 x 1250 мм. Кроме того, мы предоставляем бесплатную неограниченную резку с каждым заказом, используя современный режущий станок, чтобы точно соответствовать вашим требованиям.

Закажите листы из нержавеющей стали по телефону или онлайн.

Никогда не было более простого способа получить листы из нержавеющей стали. Просто ознакомьтесь с простыми и подробными инструкциями на нашем сайте. Кроме того, наши сотрудники отдела продаж будут рады принять ваш заказ или ответить на любые вопросы, если вы позвоните по телефону +86 13382898899 или напишите по электронной почте [email protected].

Срок доставки составляет всего один-два дня.

Важное примечание по безопасности:

Края металлических листов, которые мы продаем, не отполированы, не отшлифованы и не обработаны, поэтому они могут иметь острые края, как и любой лист нержавеющей стали. Мы напоминаем пользователям о необходимости использования, установки и обращения с этими устройствами с осторожностью.

Каковы сроки доставки?

Пробные заказы могут быть доставлены в течение недели. Для обычных заказов это занимает около двух недель.

Мы можем предоставить образцы листов нержавеющей стали для проверки качества. Образец бесплатный, вы платите только за доставку.

Мы экспортируем продукцию в более чем 42 страны, такие как Канада, Чили, Кувейт, Германия, Южная Корея, Саудовская Аравия, Сингапур и т. д.

Минимальный объем заказа составляет 1 тонну листа нержавеющей стали.

Пробные заказы могут быть доставлены в течение недели. Для обычных заказов это занимает около двух недель.