AISI 430(08Х17)лист нержавеющий

Являясь ведущим поставщиком и экспортером листовой нержавеющей стали в Китае, компания Daxun поставляет по всему миру 430 наименований листовой нержавеющей стали.

- Марка: AISI 430-08Х17

- Производство: холоднокатаный лист, горячекатаный лист, кованый лист

- Стандарт: ГОСТ ASTM, ASME, GB, DIN, JIS, ISO, EN, BS.

- Тип: холоднокатаный тонкий лист, горячекатаный толстый лист

- Поверхность: 2B, NO.1, NO.4, HL, BA, 8K и т.д.

- Длина: 2438 мм3048 мм6000 мм можно настроить

- Происхождение: TISCO, Baosteel, Pohang, Tsingshan, Delong

Мировой лидер в сфере услуг по изготовлению листов из нержавеющей стали

Лист нержавеющей стали AISI 430 (1.4016) — это ферритная нержавеющая сталь, классифицируемая на основе высокого содержания хрома. Содержание хрома составляет от 12 до 180, а повышенное содержание хрома придает этой нержавеющей стали хорошую пластичность и формуемость. Она также устойчива к коррозии от сильных кислот и, благодаря высокому содержанию хрома, имеет хорошую стойкость к окислению. Коррозионная стойкость нержавеющей стали максимизируется, когда она полируется или шлифуется. Металл отжигается, чтобы устранить его хрупкость при комнатной температуре после нагрева. Пожалуйста, обратитесь к страницам конкретных продуктов для получения уникальных размеров. Свяжитесь с нами сегодня, чтобы получить предложение на любой заказ листа нержавеющей сталиAISI 430 нестандартного размера.

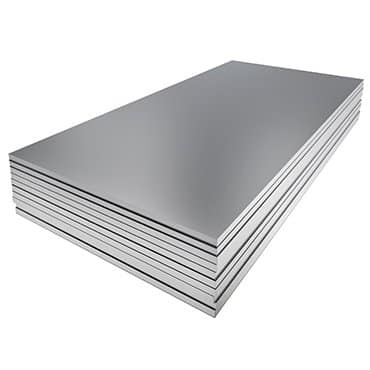

Одним из производителей, экспортеров и поставщиков листов из нержавеющей стали ss AISI430 является Daxun; качество его продукции превосходит качество продукции других поставщиков листов из нержавеющей стали AISI430, а его цены конкурентоспособны. Daxun Warehouse имеет значительный запас листов из нержавеющей стали AISI430 обычного размера и может обеспечить доставку менее чем за десять дней. Пожалуйста, не стесняйтесь обращаться к нам, если вам нужна цена листа из нержавеющей стали ss AISI430. Поскольку мы занимаемся производством и изготовлением листов из нержавеющей стали почти 20 лет, мы можем предоставить строгую гарантию качества нашей работы. Я рад, что вы выберете нашу компанию в качестве одного из ваших источников листов из нержавеющей стали AISI430.

Технические данные

- Параметр

- Химический состав

- Механические свойства

- ФИЗИЧЕСКИЕ СВОЙСТВА

- Стандарт

| Параметры продукта: Лист/Плита из нержавеющей стали | |||

| Ширина | 10мм~2500мм | ||

| Толщина | 0,2мм~100мм | Допуск толщины | +/-0,03 мм |

| Стандарт | ГОСТ 5582-75, ГОСТ 7350-77, ГОСТ 19904-90, ГОСТ 5632-72 АСТМ/АСМЕ 240/480, ДЖИС 4305, ДИН ЭН 10088-2 | ||

| Поверхность | 2B,BA,8K,NO.1,NO.4,NO.3, волосяной, клетчатый, золотой, черный, розовое золото и т. д. | ||

| спецификация | 1000*2000/Л, 1219*2438/Л, 1250*2500/Л, 1500*3000/Л1500*6000/Л, 1800*6000/Л, 2000*6000/Л2200*6000Л | ||

| Происхождение мельницы | TISCO, ZPSS, BAOSTEEL, JISCO, ZSESS, ATI, SMC, HAYNES, VDM, ArcelorMittal, Outokumpu и т. д. | ||

| Сертификация | ISO, SGS, BV, TUV, CE и т.д. | ||

| Элемент | % Присутствует (в форме продукта) | |

| С, Н, П | Л | |

| Углерод (С) | ≤0,08 | ≤0,08 |

| Кремний (Si) | ≤1.00 | ≤1.00 |

| Марганец (Mn) | ≤1.00 | ≤1.00 |

| Фосфор (P) | ≤0,040 | ≤0,040 |

| Сера (S) | ≤0,015 | ≤0,030 1) |

| Хром (Cr) | 16.00 – 18.00 | 16.00 – 18.00 |

| Железо (Fe) | Баланс | Баланс |

| Форма продукта | Толщина t или диаметр4) d мм макс. | Предел текучести Rp0.2 | Предел прочности | Удлинение мин. в % | |

| Н/мм2 | Н/мм2 | Rm Н/мм2 | A80мм1) толщина ˂3мм (продольная и поперечная) | ||

| (продольный) | (поперечный) | ||||

| С | 8 | 260 | 280 | 450 – 600 | 20 |

| ЧАС | 13.5 | 240 | 260 | 450 – 600 | 18 |

| П | 252) | 240 | 260 | 430 – 630 | 20 |

| Л3) | 100 | 240 | – | 400 – 630 | 20 (продольный) |

| Плотность при 20°C кг/м3 | 7,700 | |

| Модуль упругости кН/мм2 при | 20°С | 220 |

| 200°С | 210 | |

| 400°С | 195 | |

| 500°С | – | |

| Теплопроводность Вт/м К при 20°C | 25 | |

| Удельная теплоемкость при 20°СДж/кг К | 460 | |

| Удельное электрическое сопротивление при 20°C Ом мм2/м | 0,6 | |

| УНС S43000 | 1.4016 | БС 430С17 |

| ASTM A240 | ASTM A240 | ASTM A240 |

| ASTM A480 | ASTM A480 | ASTM A480 |

| ASME SA240 | ASME SA240 | ASME SA240 |

| АМС 5521 | АМС 5521 | АМС 5521 |

Выбирайте Daxun и сделайте своих клиентов довольными.

Быстрая доставка

Мы обеспечиваем своевременную и быструю доставку изделий из нержавеющей стали для клиентов с срочными потребностями. За скоростью стоит системная поддержка от информационного потока до логистики и движения капитала. Например, с точки зрения информационного потока данные о заказах Daxun передаются в логистическую систему в режиме реального времени, и данные бесшовно связаны; с точки зрения логистики центр обработки находится недалеко от автомагистралей, рек и морей, с разумным планированием, быстрым реагированием, складскими и транспортными связями и эффективной загрузкой, что гарантирует выполнение задачи в срок.

430 пластинчатых характеристик

- Пластина из нержавеющей стали 430 устойчива к коррозии

- Пластина из нержавеющей стали 430 имеет особую устойчивость к азотной кислоте

- Лист из нержавеющей стали марки 430 обладает хорошей формуемостью

- Пластина из нержавеющей стали марки 430 легко поддается сварке

- Лист из нержавеющей стали марки 430 хорошо поддается обработке

- Легко изготавливается методом холодной обработки.

Применение нержавеющей стали 430

Типичные области применения нержавеющей стали AISI 430 включают:

- Недорогие мойки

- Декоративная отделка

- Белые и коричневые товары

- Холодильники

- Опоры для элементов печи

- Научный аппарат

- Крепежные элементы

- Футеровка дымохода

- Автомобильная отделка

- Петли

Качество, доставка, проверка

- Daxun также проводит несколько испытаний на обеспечение качества. Эти испытания включают испытание на сплющивание, испытание на питтинг и сопротивление, механическое испытание, испытание на твердость, положительную идентификацию материала, испытание на расширение и т. д. Все эти испытания гарантируют, что материал подходит для требуемого применения.

- В процессе производства мы измеряем диаметр, толщину и поверхность изделия. Наш стандартный срок поставки составляет 7-15 дней, за исключением некоторых изделий специального размера, срок поставки увеличивается до 20 дней.

Срок поставки строго соответствует договору. - Поддержка сторонних агентств-клиентов при посещении завода для проведения инспекции

- Предоставляем бесплатные образцы клиентам для тестирования

- Поддержка инспекции завода на месте или видеоинспекции

ОБРАБОТКА

Если вам нужна дополнительная техническая помощь, наш местный металлург и знающий персонал будут рады помочь. Кроме того, Daxun может похвастаться сертифицированной испытательной лабораторией — первой в отрасли многометаллического и пластикового инвентаря. Это, по нашему мнению, демонстрирует нашу непоколебимую преданность качеству и нашу философию как поставщика полного спектра услуг.

Обработка поверхности пластины SS 430

1D: Поверхность матовая с прерывистой формой частиц.

2D: Белая с серебристым оттенком.

2B: Серебристо-серая с лучшим блеском и плоскостностью, чем у поверхности 2D.

Ba: Поверхность, близкая к зеркальной, с отличным блеском и отражающей способностью.

№ 3: Хороший блеск и шероховатая поверхность.

№ 4: Поверхность имеет тонкие линии и хороший блеск.

HL: Серебристо-серая с золотистыми волосками.

8K: Зеркальная поверхность.

Характеристики пластины из нержавеющей стали 430

Daxun Позвольте вашему бренду быстро улучшиться

- Галерея

- Состояние доставки

- Терпимость

- Другие серии продуктов

| Выбор штата доставки | Состояние поверхности |

| Холоднокатаный | 2Б |

| 2D | |

| БА | |

| Линия роста волос | |

| №3 | |

| №4 | |

| 6К | |

| 8К | |

| Примечание: | |

| 1. Если вам требуется другой штат доставки, чем указанный выше, пожалуйста, согласуйте это с нами. | |

| 2. В случае возникновения каких-либо вопросов или заказов, пожалуйста, сообщите нам о любых дополнительных требованиях, не указанных здесь. | |

| Состояние доставки | |

| Выбор штата доставки | Состояние поверхности |

| Горячекатаный | №1 |

| №3 | |

| №4 | |

| 6К | |

| 8К | |

| Маринованный | |

| Примечание: | |

| 1. Если вам требуется другой штат доставки, чем указанный выше, пожалуйста, согласуйте это с нами. | |

| 2. В случае возникновения каких-либо вопросов или заказов, пожалуйста, сообщите нам о любых дополнительных требованиях, не указанных здесь. | |

| Допуск для листа 2B | |||

| Размер | Рейтинг толерантности | ||

| Группа 1 | Группа 2 | Группа 3 | |

| 0,4 | 0,3 ~ 0,32 | 0,33 ~ 0,37 | 0,37 ~ 0,39 |

| 0,5 | 0,4 ~ 0,42 | 0,43 ~ 0,47 | 0,47 ~ 0,49 |

| 0,6 | 0,5 ~ 0,52 | 0,53 ~ 0,56 | 0,57 ~ 0,59 |

| 0,7 | 0,6 ~ 0,62 | 0,63 ~ 0,67 | 0,67 ~ 0,69 |

| 0,8 | 0,7 ~ 0,72 | 0,73 ~ 0,77 | 0,74 ~ 0,79 |

| 0.9 | 0,8 ~ 0,82 | 0,83 ~ 0,87 | 0,87 ~ 0,89 |

| 1 | 0,89 ~ 0,9 | 0,91 ~ 0,94 | 0,94 ~ 0,99 |

| 1.2 | 1,02 ~ 1,08 | 1,09 ~ 1,15 | 1,16 ~ 1,18 |

| 1.5 | 1,32 ~ 1,38 | 1,39 ~ 1,45 | 1,46 ~ 1,48 |

| 2 | 1,72 ~ 1,79 | 1,8 ~ 1,86 | 1,87 ~ 1,9 |

| 2.5 | 2,23 ~ 2,36 | 2,32 ~ 2,42 | 1,42 ~ 1,47 |

| 3 | 2,7 ~ 2,77 | 2,78 ~ 2,82 | 2,85 ~ 2,9 |

| Допуск для горячекатаного листа №1 | |||

| Размер | Рейтинг толерантности | ||

| Группа 1 | Группа 2 | Группа 3 | |

| 3 | 2,6 ~ 2,75 | 2,75 ~ 2,85 | 2,86 ~ 2,9 |

| 4 | 3,5 ~ 3,6 | 3,6 ~ 3,75 | 3,76 ~ 3,95 |

| 5 | 4,5 ~ 4,6 | 4,6 ~ 4,75 | 4,75 ~ 4,95 |

| 6 | 5.4 ~ 5.6 | 5,6 ~ 5,75 | 5,75 ~ 5,85 |

| 8 | 7.3 ~ 7.5 | 7,5 ~ 7,65 | 7,65 ~ 7,85 |

| 10 | 9.2 ~ 9.3 | 9.3 ~ 9.6 | 9,6 ~ 9,85 |

| 12 | 11.1 ~ 11.2 | 11.2 ~ 11.6 | 11,6 ~ 11,85 |

| 14 | 13.1 ~ 13.2 | 13.2 ~ 13.6 | 13,6 ~ 13,85 |

| 16 | 15.2~ 15.5 | 15.5~ 15.7 | 15.7~ 16.1 |

| 18 | 17.2~ 17.5 | 17.5~ 17.7 | 17.7~ 18.1 |

| 20 | 19.2~ 19.5 | 19.5~ 19.7 | 19.7~ 20.1 |

| 30 | 29.2~ 29.5 | 29,5~ 29,7 | 29.7-30.1 |

| 40 | 39,2~ 39,5 | 39,5~39,7 | 39,7~ 40,1 |

| 50 | 49,2~ 49,5 | 49,5~ 49,7 | 49,7~ 50,1 |

| 60 | 59.2~ 59.5 | 59,5~ 59,7 | 59,7~ 60,1 |

| Оценка | Тип | Толщина | Поверхность |

| аустенитный | 304/304H/304L/304J1 | 0,25-150 мм | 2Б/БА/№4/8К/СБ/ХЛ/№1 |

| 321 | 0,4-80 мм | 2Б/БА/№4/8К/СБ/ХЛ/№1 | |

| 316/316L/317L/316Ti | 0,3-80 мм | 2Б/БА/№4/8К/СБ/ХЛ/№1 | |

| Феррит | 430 | 0,4-3,0 мм | 2Б/БА/№4/8К/СБ/ХЛ |

| Сверхчистый феррит | 443 | 0,4-2,0 мм | 2Б |

| 436Л/439/444/441 | 0,5-3,0 мм | 2Б、2Д | |

| 409л | 0,4-2,5 мм | 2Б、2Д | |

| Оценка | Тип | Толщина | Оригинал |

| Жаропрочная сталь | 309С | 0,5-40 мм | ЧН |

| 310С | 0,5-40 мм | ЧН | |

| Дуплексная сталь | 2101 | 1,5-50 мм | ЧН |

| 2304 | 3,0-50 мм | ЧН | |

| 2205 | 0,5-60 мм | ЧН | |

| 2507 | 1,0-60 мм | Швеция / Япония / Китай | |

| Супер аустенитная сталь | N08904 | 0,6-50 мм | Швеция / Япония / Китай |

| S31254 | 0,5-50 мм | Швеция / Япония / Китай | |

| N08926 | 0,5-50 мм | Швеция / Япония / Китай | |

| N08367 | 0,5-50 мм | Швеция / Япония / Китай | |

| Сплав на основе никеля | N08031 | 1,0-50 мм | США / Япония / Германия |

| N08810/N08800 | 0,8-50 мм | США / Япония / Китай | |

| N08028 | 1,0-20 мм | США / Германия / Япония | |

| N08020 | 1,0-20 мм | США / Германия / Япония | |

| N08825 | 0,8-40 мм | США / Германия / Швеция / Япония / Китай | |

| N10276 | 0,5-50 мм | США / Германия / Япония | |

| N06022 | 1,0-50 мм | США / Германия / Япония | |

| N06625 | 0,8-20 мм | США / Германия / Китай | |

| N04400 | 1,0-20 мм | США / Германия / Япония | |

| N06600 | 1,0-50 мм | США / Германия / Япония / Китай | |

| N02201 | 0,5-20 мм | США/Япония | |

| Титан | ТА1/Гр1 | 0,5-50 мм | Япония / Китай |

| ТА2/Гр2 | 0,5-50 мм | Япония / Китай | |

| Сварочный материал | ERNiCrMo-13 | 1.2、2.4мм | ГЕР |

| ЭРНиКрМо-3 | 2.4мм | ГЕР | |

| ЭРНиКрМо-4 | 2.4мм | НАС |

Поверхность и форма пластины из нержавеющей стали AISI 430 (7)

Информация доступна для ознакомления и скачивания

Daxun — надежный производитель пластин из нержавеющей стали.

Как профессиональный производитель, Daxun гарантирует, что вся производимая нами продукция отличается высоким качеством. Поэтому мы гарантируем, что все пластины из нержавеющей стали сертифицированы по стандартам ISO9001, SGS, CE, OQC

Последние горячие проекты и продукты

Сопутствующие товары (13)

Ведущие поставщики листов из нержавеющей стали в Китае

Общие свойства:

- Ферритный, чистый хром, не закаливаемый сорт 430 имеет хорошую формуемость и коррозионную стойкость в дополнение к практическим механическим качествам. Его способность противостоять азотнокислотной коррозии делает его полезным в некоторых химических применениях; тем не менее, его основные области применения — детали приборов и отделка автомобилей.

- Для использования в автоматических винтовых машинах, марка 430F является более обрабатываемой вариацией этой марки, которая предлагается в форме прутка. Марка 434 является маркой, содержащей молибден, которая имеет те же полезные характеристики, что и марка 430. Добавленный молибден повышает коррозионную стойкость.

- ASTM A240/A240M определяет эти 430 качеств для плоского проката (пластины, листы и рулоны). Похожие, хотя и не часто идентичные, качества указаны в спецификациях других изделий, таких как прутки и поковки. ASTM A582 определяет характеристики класса 430F для прутков.

ПРИЛОЖЕНИЯ:

Типичные области применения стали марки 430 включают:

- Накладки для посудомоечных машин

- Панели холодильного шкафа

- Автомобильная отделка

- Крепежный трос

- Элементы поддержки

- Кольца для отделки плиты

- Крепежные элементы

- Дымоходные вкладыши

Типичные области применения стали марки 430F включают:

- Повторно обработанные компоненты

ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ:

- UNS: ASTM/ASTE S43000

- ДИН:1.4016

КОРРОЗИОННАЯ УСТОЙЧИВОСТЬ:

- Материал марки 430 демонстрирует хорошую устойчивость к широкому спектру коррозионных сред, таких как азотная кислота и некоторые органические кислоты. Наивысшие уровни коррозионной стойкости достигаются при тщательной полировке или шлифовке. В целом, его устойчивость к точечной и щелевой коррозии сопоставима с устойчивостью марки 304. Как и все ферритные марки, 430 демонстрирует очень высокую устойчивость к коррозионному растрескиванию под напряжением.

- Сплав 430F, не содержащий серы, демонстрирует значительно сниженную стойкость к точечной и щелевой коррозии, как и другие сорта стали с высоким содержанием серы, не содержащие серы.

ТЕПЛОУСТОЙЧИВОСТЬ:

- До 870°C при периодической эксплуатации и 815°C при непрерывной эксплуатации марка 430 устойчива к окислению. Для этой марки может потребоваться длительный нагрев в диапазоне 400–600°C, прежде чем она станет хрупкой при комнатной температуре. Для устранения этого эффекта можно использовать отжиг.

ТЕРМИЧЕСКАЯ ОБРАБОТКА:

- Отжиг на твердый раствор – Нагреть до 815-845°C, выдержать ½ часа на 25 мм толщины, медленно охладить в печи до 600°C, а затем быстро охладить на воздухе. Медленное охлаждение от 540-400°C вызовет охрупчивание.

- Докритический отжиг – нагрев до 760–815 °C, а затем охлаждение на воздухе или закалка в воде.

- Данная марка не упрочняется термической обработкой.

СВАРКА:

- При необходимости сварки предварительно нагрейте до 150–200 °C.

- Охрупчивание металла шва и зоны термического влияния можно устранить путем отжига после сварки при температуре 790-815°С.

- Измельчения зерна не произойдет.

ОБРАБОТКА:

- Легче поддается обработке, чем стандартные аустенитные марки, такие как 304.

- По-прежнему сохраняется тенденция к задирам и задирам на режущем инструменте.

- Слабовытянутые прутки легче поддаются обработке, чем отожженные.

- Сплав 430F, легкообрабатываемая версия сплава 430, гораздо легче поддается обработке.

ИЗГОТОВЛЕНИЕ:

- Более низкая степень упрочнения делает гибку и формовку несколько легче, чем у марки 304.

- Более низкая пластичность ограничивает очень тяжелые условия эксплуатации.

- Сильные изгибы следует выполнять так, чтобы ось изгиба располагалась под прямым углом к направлению прокатки.

- Возможна интенсивная холодная высадка проволоки 430.

Листы из нержавеющей стали марки 430 с различными вариантами отделки

Наши листы из нержавеющей стали (иногда называемые стальными листами) доступны в различных вариантах отделки: шлифованная, гладкая 2B или зеркальная 8K.

Отделочная сторона каждого поставляемого нами листа нержавеющей стали покрыта пленкой. Эта пленка легко снимается после изготовления или установки и защищает поверхность материала от износа и следов. Обратная сторона необработанная.

Листовая нержавеющая сталь марки 430 является наиболее часто используемым сортом. Она легко сваривается, формуется и имеет хорошую коррозионную стойкость.

Мы можем оказать помощь в поставке листов из нержавеющей стали любого необходимого размера.

Чтобы удовлетворить ваши особые требования, наши листы из нержавеющей стали доступны в трех вариантах отделки и различных размерах. Мы можем с легкостью предоставить любой необходимый вам индивидуальный размер с помощью нашей бесплатной неограниченной услуги по резке.

Мы можем удовлетворить любые потребности в размерах толщиной от 0,3 до 30 мм и размером от 50 x 50 мм до 2500 x 1250 мм. Кроме того, мы предоставляем бесплатную неограниченную резку с каждым заказом, используя современный режущий станок, чтобы точно соответствовать вашим требованиям.

Закажите листы из нержавеющей стали по телефону или онлайн.

Никогда не было более простого способа получить листы из нержавеющей стали. Просто ознакомьтесь с простыми и подробными инструкциями на нашем сайте. Кроме того, наши сотрудники отдела продаж будут рады принять ваш заказ или ответить на любые вопросы, если вы позвоните по телефону +86 13382898899 или напишите по электронной почте [email protected].

Срок доставки составляет всего один-два дня.

Важное примечание по безопасности:

Края металлических листов, которые мы продаем, не полируются, не шлифуются и не обрабатываются, поэтому они могут быть острыми, как и края любого листа из нержавеющей стали. Мы напоминаем пользователям о необходимости использования, установки и обращения с этими устройствами с осторожностью.

Мы можем предоставить образцы листов нержавеющей стали для проверки качества. Образец бесплатный, вы платите только за доставку.

Мы экспортируем продукцию в более чем 42 страны, такие как Канада, Чили, Кувейт, Германия, Южная Корея, Саудовская Аравия, Сингапур и т. д.

Минимальный объем заказа составляет 1 тонну листа нержавеющей стали.

Пробные заказы могут быть доставлены в течение недели. Для обычных заказов это занимает около двух недель.