Daxun — поставщик рулонов нержавеющей стали марки 304/304L из Китая.

Являясь ведущим поставщиком и экспортером рулонной нержавеющей стали в Китае, компания Daxun поставляет рулонную нержавеющую сталь по всему миру.

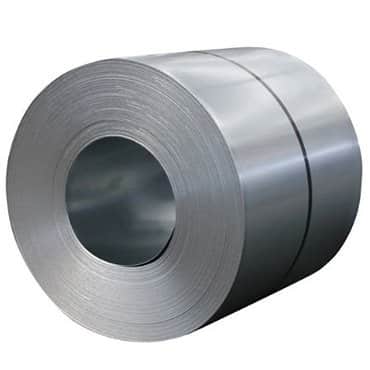

- Марка рулона: S30400-S30403

- Толщина рулона: от 0,4 мм до 12,00 мм

- Ширина рулона: 1000 мм, 1250 мм, 1500 мм и 2000 мм.

- Поверхность катушки: 2B, BA, матовая, полированная, 8k зеркало.

- При необходимости рулон нержавеющей стали может быть покрыт защитной пленкой, которая защитит поверхность металла от ненужных повреждений.

Мировой лидер в сфере услуг по изготовлению рулонов нержавеющей стали

Daxun Metal предлагает полный ассортимент высококачественной рулонной нержавеющей стали SS 304/304L. Daxun стремится оставаться на переднем крае технологий и практики, чтобы мы всегда могли предоставить вашему бизнесу рулонную нержавеющую сталь 304 высочайшего качества. Цель Daxun — безопасное производство и продажа рулонной нержавеющей стали высочайшего качества и поставка ее клиентам по всему миру. Свяжитесь с Daxun сегодня, и мы станем вашим предпочтительным поставщиком рулонной нержавеющей стали 304/304L!

Рулон нержавеющей стали 304 — это рулон из низкоуглеродистой аустенитной нержавеющей стали с содержанием молибдена. Его химический состав содержит не менее 18% хрома и 8% никеля. Эти марки рулонов нержавеющей стали используются, поскольку они устойчивы к широкому спектру химических коррозионных веществ, а также обладают высокими механическими качествами. Нержавеющая сталь марки 304 устойчива к коррозии, что делает ее идеальной для оборудования для переработки пищевых продуктов и хирургических инструментов. Она обладает превосходной формуемостью и свариваемостью по сравнению с другими марками нержавеющей стали. Daxun — известный производитель, продавец и поставщик рулонов нержавеющей стали 304. Рулоны стали изготавливаются с высокой точностью и соответствуют международным стандартам качества.

Daxun — сертифицированная по стандарту ISO 9001:2008 фирма, которая специализируется на поставках и экспорте рулонов нержавеющей стали ASTM A240 304. Рулон нержавеющей стали 304 может быть разрезан по вашим спецификациям и поставляется с полным набором результатов заводских испытаний. Доступны индивидуальные длины и ширины до 2000 мм. Экспорт — наша специализация! Мы можем получить несколько труднодоступных марок и/или нестандартных размеров, чтобы удовлетворить особые потребности наших клиентов. Благодаря нашему значительному опыту в обработке рулонной стали мы можем разрезать все рулоны стали ASTM SS 304 до нужного размера.

- Параметр

- Элемент

- Механические свойства

- ФИЗИЧЕСКИЕ СВОЙСТВА

- Все эквивалентно

- 304 рулонный запас

| Технические характеристики рулона нержавеющей стали SS 304 / 304L | GOST ASTM A240 / ASME SA240 |

| Процесс производства рулонов нержавеющей стали SS 304 / 304L | Горячекатаный (HR) / Холоднокатаный (CR) |

| Марки рулонной нержавеющей стали SS 304 / 304L | 202 / SS 304 / 304L / SS 304 / 304LL / SS 304 / 304LH / 309S / 310S / 316 / 316L / 316Ti / 317L / 321 / 321H / 347 / 347H / 904L и т. д. |

| Номер UNS – UNS SSS 304/304L00, UNS SSS 304/304L03, UNS S31008, UNS S31620, UNS S31603, UNS S31603, UNS S31635, UNS S31703, UNS S32100, UNS S34700, UNS С34709, УНС С8904 | |

| № EN – 1.4301, 1.4307, 1.4845, 1.4401, 1.4404, 1.4571, 1.4438, 1.4541, 1.4550, 1.4551, 1.4539 | |

| Толщина рулона нержавеющей стали SS 304 / 304L | ТОЛЩИНА ОТ 0,6 ММ ДО 80 ММ |

| Ширина рулона нержавеющей стали SS 304 / 304L | 1250 мм / 1500 мм / 2000 мм / 04 фута / 05 футов и индивидуальная ширина резки по требованию |

| Длина рулона нержавеющей стали SS 304 / 304L | 2400 мм / 2420 мм / 6000 мм / 08 футов / 10 футов / Длина рулона и индивидуальная длина по требованию |

| Поверхностная отделка рулона нержавеющей стали SS 304 / 304L | 2B, 2D, BA, МАТОВЫЙ, МАТОВЫЙ ПВХ, № 4, № 5, SB, HR, № 8, Зеркальный, Волосяной, Кисть, Текстурированный, Масляная основа, Мокрая полировка, Полировка с обеих сторон. |

| Покрытие рулонов нержавеющей стали SS 304 / 304L | ПВХ-покрытие Обычное / Лазерное, Пленка: 100 микрометров, Цвет: черный/белый. |

| SS 304 / 304L нержавеющая сталь катушка Другие испытания | NACE MR0175, ультразвуковой тест, тест IGC, испытание на межкристаллитную коррозию согласно ASTM A262 Practice E, испытание на удар по Шарпи, макроопределение, размер зерна, твердость и т. д. |

| SS 304 / 304L Нержавеющая сталь в рулонахУслуги с добавленной стоимостью | Газовая резка / плазменная резка с ЧПУ / профилирование / прокатка / гибка / изготовление листового металла / сверление / перфорация / механическая обработка / пескоструйная обработка / дробеструйная обработка / термообработка |

| Упаковка рулонов нержавеющей стали SS 304 / 304L | Насыпью / Каррата / Деревянный поддон / Деревянный ящик-a / Пластиковые тканевые обертки |

| Отгрузка и транспортировка рулонов нержавеющей стали SS 304 / 304L | По дороге – Грузовик / Поезд Частичная загрузка, Полная загрузка, По морю – Конвенциональное судно для перевозки генеральных грузов / FCL (Полная загрузка контейнера) / LCL (Меньшая загрузка контейнера) / 20-футовый контейнер / 40-футовый контейнер / 45-футовый контейнер / Контейнер High Cube / Контейнер с открытым верхом, По воздуху – Грузовые гражданские пассажирские и грузовые самолеты |

| Сертификат испытания материала рулона нержавеющей стали SS 304 / 304L | Сертификат испытаний производителя согласно EN10204 3.1, 3.2 / Сертификат лабораторных испытаний от лаборатории, одобренной NABL. / Под сторонним инспекционным агентством, таким как SGS, TUV, DNV, LLOYDS, ABS, Бюро индийских стандартов, одобрено BIS и т. д. |

| Производитель | POSCO, Aperam, Jindal Stainless, DKC Korea, Thyssenkrup, Baosteel, TISCO, Arcelor Mittal, VDM, Nippon Metal, Outokumpu, Qingshan, Delong. |

| Порт отправки | Шанхай/Порт Нинбо/Тяньцзинь/Циндао |

| Состав труб и труб 304/304L/304LN/304H | ||||

| Оценка | 304 | 304L | 304ЛН | 304H |

| Обозначение UNS | S30400 | S30403 | S30453 | S30409 |

| Углерод (C) Макс. | 0,08 | 0,030* | 0,03 | 0,04 – 0,10 |

| Марганец (Mn) Макс. | 2 | 2 | 2 | 2 |

| Фосфор (P) Макс. | 0,045 | 0,045 | 0,045 | 0,045 |

| Сера (S) Макс. | 0,03 | 0,03 | 0,03 | 0,03 |

| Кремний (Si) Макс. | 1 | 1 | 1 | 1 |

| Хром (Cr) | 18,0–20,0 | 18,0–20,0 | 18,0–20,0 | 18,0–20,0 |

| Никель (Ni) | 8,0–11,0 | 8,0–11,0 | 8,0–11,0 | 8,0–11,0 |

| Молибден (Mo) | — | — | — | — |

| Азот (N) | — | — | 0,10–0,15 | — |

| Железо (Fe) | Бал. | Бал. | Бал. | Бал. |

| Другие элементы | — | — | — | — |

| Тип | Предел текучести 0,2% смещения (KSI) | Прочность на растяжение (KSI) | % удлинения (длина 2 дюйма) |

| 304 Энн | 30 мин. | 75 мин. | 40 мин. |

| 304 ¼ Жесткий | 75 мин. | 125 мин. | 12 мин. |

| 304 ½ Твердый | 110 мин. | 150 мин. | 7 мин. |

| 304L Энн | 25 мин. | 70 мин. | 40 мин. |

| 304L ¼ Твердый | 75 мин. | 125 мин. | 12 мин. |

| 304L ½ Твердый | 110 мин. | 150 мин. | 6 мин. |

| 304 и 304L | ||

| Плотность (фунт/дюйм^2) при комнатной температуре | 0,29 | |

| Модуль упругости при растяжении (psi x 10^6) | 28 | |

| Удельная теплоемкость (БТЕ/o F/фунт) | от 32 до 212 oF | 0,12 |

| Теплопроводность (БТЕ/ч/фут^2/фут) | 212oF | 9.4 |

| 932oF | 12.4 | |

| Средний коэффициент теплового расширения (дюйм x 10^-6 на o F) | от 32 до 212oF | 9.2 |

| от 32 до 600oF | 9.9 | |

| от 32 до 1000oF | 10.2 | |

| от 32 до 1200oF | 10.4 | |

| Удельное электрическое сопротивление (мкОм – см) | при 70oF | 72 |

| Диапазон температур плавления (oF) | 2550-2650 | |

| Стойкость к окислению – непрерывная эксплуатация (oF) | 1,650 | |

| Стойкость к окислению – периодическая эксплуатация (oF) | 1500 |

| СТАНДАРТ | ВЕРКСТОФФ НОМЕР. | УНС | JIS | БС | ГОСТ | АФНОР | RU |

| СС 304 | 1.4301 | S30400 | СУС 304 | 304С31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

| • Змеевик HR из нержавеющей стали 304 | • Рулон нержавеющей стали Baosteel 304 |

| • Рифленая катушка из нержавеющей стали 304 | • Покрытие из нержавеющей стали 304, катушка |

| • Катушка с золотым лазерным узором из нержавеющей стали 304 | • Черная спираль SS 304 толщиной 4 мм |

| • Сверхтонкая зеркальная поверхность BA ss 304 Катушка | • Катушка из нержавеющей стали марки 304, протравленная до блеска |

| • Рулон из супераустенитной стали SS 304 | • Холоднокатаная, термообработанная рулонная сталь 304 |

| • ASTM A240 304 катушка | • Холоднокатаная рулонная сталь AISI SS 304 толщиной 3 мм |

| • JMSS холоднокатаная рулонная сталь ss 304 | • Поставка фабрики рулонов SS 304 |

| • Холоднокатаная рулонная сталь SS 304 с отделкой №1 | • Катушка из высококачественной нержавеющей стали SS 304 |

| • SEW 400 Катушка из нержавеющей стали 304 | • Катушка из нержавеющей стали Carpenter Custom 450 304 |

| • Горячекатаная рулонная нержавеющая сталь 304 | • Нарезанная по размеру рулонная нержавеющая сталь 304 |

| • Рекламная акция: катушка SS 304 | • Немагнитная полировка катушки из нержавеющей стали 304 |

| • Рулон из хромированной нержавеющей стали 304 | • Катушка ASME SA240 304 |

| • Сертификат заводских испытаний рулона SS 304 | • Отделка катушки из нержавеющей стали марки 304 |

| • ASTM A240 304 катушка | • Пустая катушка из нержавеющей стали 304 |

| • Холоднокатаная, светлоотожженная рулонная сталь 304 | • Перфорированная катушка из нержавеющей стали 304 |

| • Шлифованная катушка из нержавеющей стали 304 | • Рельефная сталь ss 304, катушка |

| • Популярная катушка AISI SS 304 | • Дешевая холоднокатаная сталь ss 304 в рулонах по лучшей цене |

| • SS 304 розово-золотистая спираль | • Прайс-лист на рулоны из нержавеющей стали 304 с отделкой щеткой |

| • Поверхностно-покрытая катушка из нержавеющей стали 304 | • Катушка SS URANUS B6 304 |

| • Сатинированная отделка, нержавеющая сталь 304, рулон | • 2B SUS SS 304 катушка |

| • Бронированная катушка из нержавеющей стали AISI 304 | • Катушка из пищевой нержавеющей стали 304 |

| • Сатинированная отделка, нержавеющая сталь 304, рулон | • № 4 рулона нержавеющей стали SS 304 с покрытием из ПВХ |

| • Зеркальная отделка рулона нержавеющей стали SS 304 | • SS 304 Coil Blasted Tin-Gold Rose |

| • SS 304, отделка щеткой из золота | • 2 мм ASTM SS 304 катушка |

| • Катушка CR из нержавеющей стали 304 | • Гофрированная катушка из нержавеющей стали 304 |

| • Катушка 2B из нержавеющей стали 304 | • ASTM B625 304 катушка |

| • Профильная катушка BQ из нержавеющей стали 304 | • Матовая или матово-полированная катушка из нержавеющей стали марки 304 |

| • Самая продаваемая катушка из нержавеющей стали 304 размером 4×8 футов с зеркальной полировкой | • Холоднокатаная, термообработанная, травленая рулонная сталь 304 |

| • Декоративная полоса из нержавеющей стали, холоднокатаная, рулон ss 304 | • 10К зеркальная поверхность, катушка из нержавеющей стали 304 |

| • Отделка линии роста волос SS 304 катушка | • Катушка из нержавеющей стали SS 304 с золотым травлением |

| • Лазерная резка рулона нержавеющей стали 304 | • Катушка SS 304 калибра 18 |

| • Поставщик Tisco, рулон нержавеющей стали 304 толщиной 3 мм | • Узорчатая катушка из нержавеющей стали 304 |

| • Декоративная катушка из нержавеющей стали 304 | • Рулон из нержавеющей стали 304 с отделкой №4 |

| • Скотч Брайт SS 304 катушка | • Узорчатая катушка из нержавеющей стали 304 |

| • Размерная катушка из нержавеющей стали марки 304 | • Кабина пассажирского лифта SS 304 Coil |

Выбирайте Daxun и сделайте своих клиентов довольными.

Быстродействующая катушка из нержавеющей стали 304

Мы обеспечиваем своевременную и быструю доставку изделий из нержавеющей стали для клиентов с срочными потребностями. За скоростью стоит системная поддержка от информационного потока до логистики и движения капитала. Например, с точки зрения информационного потока данные о заказах Daxun передаются в логистическую систему в режиме реального времени, и данные бесшовно связаны; с точки зрения логистики центр обработки находится недалеко от автомагистралей, рек и морей, с разумным планированием, быстрым реагированием, складскими и транспортными связями и эффективной загрузкой, что гарантирует выполнение задачи в срок. Материалы из нержавеющей стали Daxun имеют надежное качество, а их разновидности, спецификации и вес поставки строго соответствуют стандартам.

Преимущества Даксуна

Качество — это вера, а честность — это визитная карточка. Daxun стала пионером концепции «управления эффективностью» и внедрила модель управления «PDCA+Lean». Визитная карточка компании гласит: «Daxun = гарантированное качество». Daxun Stainless Steel достигает полной прослеживаемости каждого рулона нержавеющей стали 304 из системы ERP, включая ассортимент, спецификации и происхождение, а также выступает и поощряет борьбу с подделками в отрасли. Daxun Stainless Steel полагается на технологии для обработки и настройки, а высокая точность и высокое качество являются отраслевыми эталонами; с точки зрения обслуживания она продвигает управление жизненным циклом продукта, предоставляет профессиональные решения по выбору материалов и обработке перед продажей, строгий мониторинг во время продажи и предоставляет гарантии беспроблемного обслуживания после продажи.

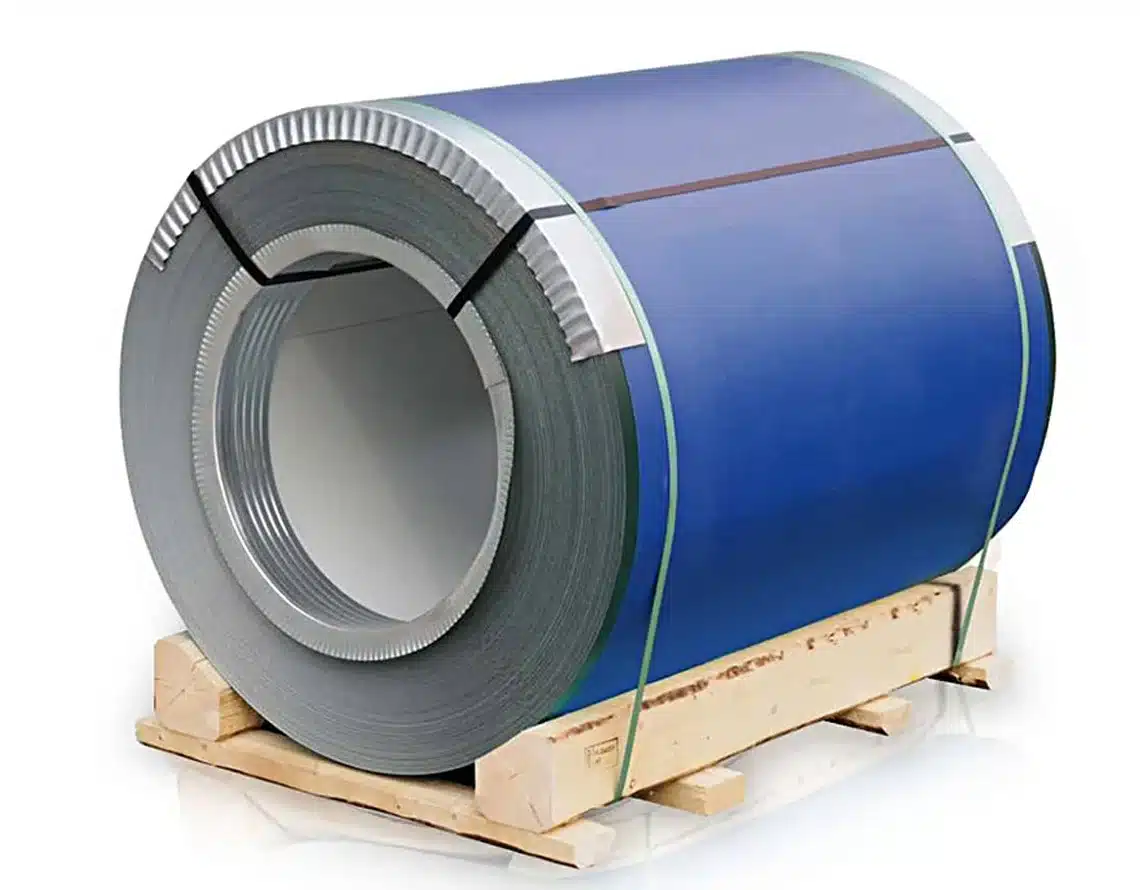

Упаковка рулонов нержавеющей стали

Daxun Alloy гарантирует наилучшее качество упаковки, поскольку она играет важную роль в международных грузоперевозках, где товары проходят через различные каналы, чтобы достичь конечного пункта назначения, поэтому мы уделяем особое внимание упаковке. Мы упаковываем наши товары разными способами в зависимости от продукта. Мы упаковываем наши продукты разными способами, такими как:

• Коробки и ящики

• Термоусадочная пленка

• Деревянные поддоны

• Деревянные ящики

Качество, доставка, проверка

- Daxun также проводит несколько испытаний на обеспечение качества. Эти испытания включают испытание на сплющивание, испытание на питтинг и сопротивление, механическое испытание, испытание на твердость, положительную идентификацию материала, испытание на расширение и т. д. Все эти испытания гарантируют, что материал подходит для требуемого применения.

- В процессе производства мы измеряем диаметр, толщину и поверхность изделия. Наш стандартный срок поставки составляет 7-15 дней, за исключением некоторых изделий специального размера, срок поставки увеличивается до 20 дней.

Срок поставки строго соответствует договору. - Поддержка сторонних агентств-клиентов при посещении завода для проведения инспекции

- Предоставляем бесплатные образцы клиентам для тестирования

- Поддержка инспекции завода на месте или видеоинспекции

Информация для заказа рулона нержавеющей стали 304

Заказы на закупку должны включать количество, сорт, тип или категорию, ссылку API5L, толщину, ширину, длину и любые применимые приложения или дополнительные требования, связанные с химическим составом, механическими свойствами, термической обработкой, дополнительными испытаниями, производственным процессом, покрытием поверхности или конечной отделкой. Свяжитесь с Daxun сейчас, мы ответим на ваше письмо как можно скорее.

Техническая поддержка

Если вам нужна дополнительная техническая помощь, наш местный металлург и знающий персонал будут рады помочь. Кроме того, Daxun может похвастаться сертифицированной испытательной лабораторией — первой в отрасли многометаллического и пластикового инвентаря. Это, по нашему мнению, демонстрирует нашу непоколебимую преданность качеству и нашу философию как поставщика полного спектра услуг.

Характеристики рулона нержавеющей стали SS 304

Daxun Alloy Позвольте вашему бренду быстро улучшиться

- Галерея

- Серия продуктов

- Основное оборудование

| Оценка | Тип | Толщина | Поверхность |

| аустенитный | 304/304H/304L/304J1 | 0,25-150 мм | 2Б/БА/№4/8К/СБ/ХЛ/№1 |

| 321 | 0,4-80 мм | 2Б/БА/№4/8К/СБ/ХЛ/№1 | |

| 316/316L/317L/316Ti | 0,3-80 мм | 2Б/БА/№4/8К/СБ/ХЛ/№1 | |

| Феррит | 430 | 0,4-3,0 мм | 2Б/БА/№4/8К/СБ/ХЛ |

| Сверхчистый феррит | 443 | 0,4-2,0 мм | 2Б |

| 436Л/439/444/441 | 0,5-3,0 мм | 2Б、2Д | |

| 409л | 0,4-2,5 мм | 2Б、2Д | |

| Супер аустенитная сталь | N08904 | 0,6-50 мм | Швеция / Япония / Китай |

| S31254 | 0,5-50 мм | Швеция / Япония / Китай | |

| N08926 | 0,5-50 мм | Швеция / Япония / Китай | |

| N08367 | 0,5-50 мм | Швеция / Япония / Китай | |

| Сплав на основе никеля | N08031 | 1,0-50 мм | США / Япония / Германия |

| N08810/N08800 | 0,8-50 мм | США / Япония / Китай | |

| N08028 | 1,0-20 мм | США / Германия / Япония | |

| N08020 | 1,0-20 мм | США / Германия / Япония | |

| N08825 | 0,8-40 мм | США / Германия / Швеция / Япония / Китай | |

| N10276 | 0,5-50 мм | США / Германия / Япония | |

| N06022 | 1,0-50 мм | США / Германия / Япония | |

| N06625 | 0,8-20 мм | США / Германия / Китай | |

| N04400 | 1,0-20 мм | США / Германия / Япония | |

| N06600 | 1,0-50 мм | США / Германия / Япония / Китай | |

| N02201 | 0,5-20 мм | США/Япония | |

| Титан | ТА1/Гр1 | 0,5-50 мм | Япония / Китай |

| ТА2/Гр2 | 0,5-50 мм | Япония / Китай | |

| Сварочный материал | ERNiCrMo-13 | 1.2、2.4мм | ГЕР |

| ЭРНиКрМо-3 | 2.4мм | ГЕР | |

| ЭРНиКрМо-4 | 2.4мм | НАС |

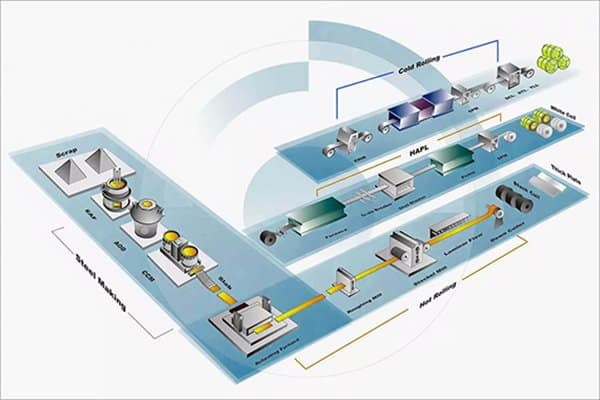

| Дочерняя компания | Основное оборудование | Кол-во | Годовая мощность |

| Компания Daxun из нержавеющей стали (Цзянсу) | Машина для продольной резки | 1 | Декоративный лист: 60 000 тонн |

| Машина для резки | 1 | ||

| № 4 и шлифовальная машина для листов с волосяным слоем | 1 | ||

| № 4/Машины для полировки катушек с волосяным стержнем | 1 | ||

| 8K/Super Mirror Лист к листу полировальные машины | 2 | ||

| 8K/Super Mirror Катушка к катушке полировальные машины | 3 | ||

| Машины для нанесения цветного покрытия методом PVD | 4 | ||

| Машины для нанесения жидких химических покрытий | 2 | ||

| Машины для защиты от отпечатков пальцев | 2 | ||

| Автоматические машины Pick and Place | 16 | ||

| Стиральная машина из нержавеющей стали 304 | 1 | ||

| Daxun Stainless Steel Co. (Шанхай) | Машина холодной прокатки | 3 | 2B Рулоны: 100 000 тонн |

| Линия отжига и травления | 2 | Декоративный лист;30 000 тонн | |

| Машина для продольной резки | 1 | ||

| Машина для резки по длине | 1 | ||

| № 4/HL Полировальный станок (лист к листу) | 3 | ||

| Полировальный станок 8K (лист к листу) | 13 | ||

| Машина для нанесения покрытия PVD титаном | 4 | ||

| Машины для нанесения жидких химических покрытий | 1 | ||

| Daxun Stainless Steel Co. (Шаньдун) | Машина холодной прокатки | 3 | Рулон 2B и BA: 220 000 тонн |

| Линия отжига и травления (2B и BA) | 2 | Декоративный лист: 60 000 тонн | |

| Снятие натяжения и проход кожи | 1 | ||

| Машина для продольной резки | 1 | ||

| Машина для резки по длине | 1 | ||

| № 4/HL Полировальный станок (лист к листу) | 1 | ||

| Полировальный станок 8K (лист к листу) | 11 | ||

| Автоматическая машина для нанесения медного покрытия | 1 | ||

| Цифровая печатная машина | 1 | ||

| Машина для нанесения покрытия PVD титаном | 3 | ||

| Машины для нанесения жидких химических покрытий | 1 | ||

| Машина против пальцев | 1 | ||

| Daxun Stainless steel co.(Сычуань) | Машина для продольной резки | 1 | 2B и BA Рулон: 180 000 тонн |

| Машина для резки | 1 | Декоративный лист: 50 000 тонн | |

| № 4 и шлифовальная машина для листов с волосяным слоем | 1 | ||

| № 4/Машины для полировки катушек с волосяным стержнем | 1 | ||

| 8K/Super Mirror Лист к листу полировальные машины | 1 | ||

| 8K/Super Mirror Катушка к катушке полировальные машины | 1 | ||

| Машины для нанесения цветного покрытия методом PVD | 1 | ||

| Машины для нанесения жидких химических покрытий | 1 | ||

| Машины для защиты от отпечатков пальцев | 1 |

Типы поверхности рулонов нержавеющей стали SS304 (6)

Информация доступна для ознакомления и скачивания

Daxun — надежный производитель рулонов нержавеющей стали.

Как профессиональный производитель, Daxun гарантирует, что вся производимая нами продукция отличается высоким качеством. Поэтому мы гарантируем, что все виды нержавеющей стали сертифицированы по стандартам ISO9001, SGS, CE, OQC

Последние горячие проекты и продукты

Сопутствующие товары (11)

Ведущие поставщики рулонной нержавеющей стали в Китае

Daxun занимается международным бизнесом более десяти лет. В 2023 году его экспортная выручка превысила 100 миллионов долларов США, а объем экспорта вошел в число ведущих китайских производителей нержавеющей стали. Daxun продолжает совершенствовать свои навыки обслуживания. Чтобы обслуживать мировой рынок, мы создали три экспортных сервисных центра в Китае и сотрудничаем с инжиниринговыми предприятиями, сталелитейными заводами и международными торговыми компаниями. Daxun предоставляет услуги по изготовлению цепей из нержавеющей стали и установила долгосрочные отношения сотрудничества с десятками известных сталелитейных заводов по всему миру. Его запасы включают 50 000 тонн обычных рулонов нержавеющей стали и 20 000 тонн дуплексной стали, сплавов на основе никеля, жаропрочной стали и других металлов. Материалы из нержавеющей стали Daxun отличаются стабильным качеством. Типы, спецификации и вес поставки строго соответствуют стандартам.

304 НЕРЖАВЕЮЩАЯ СТАЛЬ Стоимость

- Относительно низкая стоимость этого сорта нержавеющей стали приводит к более частому использованию его инженерами и архитекторами. Поскольку он легкий, вы можете упаковать больше за фунт.

В каких областях можно использовать рулоны из нержавеющей стали марки 304?

Рулоны из нержавеющей стали 304 могут использоваться в различных областях, включая:

- 1. Переработка продуктов питания и напитков.

Рулоны нержавеющей стали марки 304 используются в пищевом секторе для изготовления оборудования, такого как водонагреватели, котлы и резервуары. 2. Медицинское оборудование - 2. Больницы используют рулоны нержавеющей стали марки 304 для производства широкого спектра медицинского оборудования, такого как операционные столы, судна и детские инкубаторы.

- 3. Промышленное оборудование

Производители промышленного оборудования используют рулоны нержавеющей стали марки 304 для таких деталей, как клапаны и насосы в своей продукции. - 4. Строительное оборудование

Строительные подрядчики используют рулоны нержавеющей стали марки 304 для создания атмосферостойких материалов, которые защищают конструкции от дождя и снега во время строительства или ремонта.

Характеристики катушек из нержавеющей стали марки 304

Катушки из нержавеющей стали 304 имеют следующие характеристики:

- 1. Рулоны из нержавеющей стали 304 обладают высокой прочностью, твердостью, износостойкостью, коррозионной стойкостью и теплопроводностью.

- 2. Катушки из нержавеющей стали 304 обладают высокой термостойкостью (до 870 градусов).

- 3. Катушки из нержавеющей стали марки 304 обладают хорошими антиокислительными свойствами и могут использоваться в различных областях;

- 4. Рулоны из нержавеющей стали марки 304 широко используются в различных отраслях промышленности, включая пищевую, химическую и металлургическую.

- 5. Хотя рулоны нержавеющей стали марки 304 дешевле, чем другие марки, их цена будет быстро расти по мере роста спроса.

ОБРАБОТКА:

Типы 304 и 304L не могут быть закалены термической обработкой. Отжиг: Нагреть до 1850o F – 2050 o F и охладить с достаточно высокой скоростью до 1500oF – 800oF, чтобы избежать осаждения карбидов хрома. Отжиг для снятия напряжений: Холоднообработанные детали следует снять напряжения при 750oF в течение ½ – 2 часов.

ФОРМИРОВАНИЕ:

Отожженные типы 304 и 304L могут быть изготовлены методом прокатки, глубокой вытяжки, гибки и большинства других методов изготовления. Из-за высокой скорости упрочнения этих материалов для успешного изготовления детали могут потребоваться промежуточные отжиги.

СВАРКА:

Типы 304 и 304L свариваются большинством методов сварки плавлением или сопротивлением. Если требуется присадочный металл, обычно используется тип 308. Тип 304L следует использовать в более толстых сечениях, чтобы уменьшить возникновение карбидных осадков в зоне термического воздействия, прилегающей к сварочной ванне

КОРРОЗИЯ:

Типы 304 и 304L обеспечивают коррозионную стойкость в широком диапазоне умеренно окислительных и восстановительных условий, в пресной воде и неморских условиях.

Какие поверхности обычно используются в рулонах из нержавеющей стали?

Отделка поверхности рулона нержавеющей стали 201 может различаться в зависимости от используемых методов обработки холодной прокатки и обработки поверхности после прокатки. Поверхностная обработка рулонов нержавеющей стали включает в себя NO.1, 2B, 4, HL, 6, 8, BA, TR hard, heavy rolling bright 2H, polished bright и другие виды обработки поверхности:

- NO.1: Поверхность, полученная после горячей прокатки, термической обработки и травления полосы нержавеющей стали. Используется для удаления черной оксидной окалины, образованной травлением или аналогичными процессами во время горячей прокатки и термической обработки. Занимает первое место в обработке поверхности. Поверхность № 1 серебристо-белая и матовая. Обычно используется в жаропрочных и коррозионно-стойких отраслях промышленности, где не требуется высокий блеск поверхности, например, в спиртовой промышленности, химической промышленности, больших контейнерах и т. д.

- 2B: В отличие от поверхности 2D, поверхность 2B сглаживается легким валиком, и поверхность становится ярче. Значение шероховатости поверхности Ra, измеренное оборудованием, составляет от 0,1 до 0,5 мкм, что является типичным значением для большинства типов обработки. Эта поверхность из полосы нержавеющей стали обладает самой сильной адаптивностью и подходит для таких отраслей, как химическая, бумажная, нефтяная, медицинская, а также для широкого спектра областей, таких как строительство навесных стен.

- Твердая поверхность TR: нержавеющая сталь TR также называется твердой сталью. Ее характерные марки стали включают 304 и 301, которые используются для изделий, требующих высокой прочности и твердости, таких как железнодорожные транспортные средства, конвейерные ленты, пружины и шайбы. Идея состоит в том, чтобы использовать характеристики упрочнения аустенитной нержавеющей стали для повышения прочности и твердости рулона нержавеющей стали 304 с помощью методов холодной обработки, таких как прокатка. Чтобы заменить нежную плоскостность базовой поверхности 2B, твердый материал осторожно прокатывают на несколько процентов или десятков процентов, и отжиг после прокатки не выполняется. Таким образом, твердая поверхность TR твердого материала представляет собой прокатанную поверхность после процесса холодной прокатки.

- Повторно прокатанный блестящий 2H: После операции прокатки полоса нержавеющей стали будет подвергнута светлому отжигу. Для быстрого охлаждения полосы можно использовать линию непрерывного отжига. Полоса нержавеющей стали движется вдоль линии со скоростью 60-80 м/мин. После этого процесса отделка поверхности будет 2H повторно прокатанный блестящий.

- № 4: Поверхность № 4 имеет хороший полирующий эффект и ярче, чем № 3. Ее также можно получить путем полировки холоднокатаной рулонной нержавеющей стали 304 с поверхностью 2D или 2B, а затем полировки обработанной поверхности шлифовальной лентой с размером частиц 150-180#. Инструмент измеряет шероховатость поверхности (Ra) от 0,2 до 1,5 мкм. Поверхность № 4 широко используется в ресторанах и кухонном оборудовании, медицинском оборудовании, архитектурном декоре, контейнерах и других приложениях.

- HL: Поверхность HL часто называют волосяной отделкой. Японский стандарт JIS определяет непрерывную волосяную абразивную поверхность, полученную путем полировки абразивной лентой 150-240#. Ограничения по китайскому стандарту GB3280 неясны. Отделка поверхности HL обычно используется для архитектурного декора, такого как лифты, эскалаторы и наружные стены.

- № 6: Поверхность № 6 дополнительно полируется на основе № 4 щеткой Tampico или абразивным материалом зернистостью W63, указанным в стандарте GB2477. Поверхность имеет хороший металлический блеск, мягкость, слабое отражение и отсутствие образов. Благодаря своим хорошим характеристикам она очень подходит для навесных стен, декорирования кисточками и кухонных принадлежностей.

- BA: BA — это поверхность, которая подвергается яркой термообработке после холодной прокатки. Яркая термообработка — это отжиг в защитной атмосфере, чтобы поверхность не окислялась и сохраняла блеск холоднокатаной поверхности, а затем ее полируют высокоточным гладким роликом для улучшения яркости поверхности. Прибор оценивает шероховатость поверхности как 0,05–0,1 мкм, что указывает на то, что поверхность близка к зеркальной поверхности. Поверхности BA могут использоваться в различных областях, включая пищевую посуду, бытовую технику, медицинское оборудование, автомобильные детали и украшения.

- № 8: Зеркальная поверхность, максимальная отражательная способность, отсутствие абразивных частиц. Индустрия глубокой обработки нержавеющей стали также относится к 8K-доске. Материал BA часто используется в качестве сырья для обработки зеркал. Его нужно только отполировать. Поверхность красива после обработки зеркалом и часто используется для входов в здания и внутренней отделки.

Какова стандартная морская упаковка рулона нержавеющей стали?

- Стандартная экспортная морская упаковка:

водонепроницаемая бумажная обмотка + ПВХ-пленка + обвязка лентой + деревянный поддон или деревянный ящик; - Индивидуальная упаковка по вашему запросу (на упаковке допускается печать логотипа или другого содержимого);

- Другая специальная упаковка будет разработана по запросу клиента;

доступны как варианты «глазом к стене», так и «глазом к небу»; - Международная экспресс-доставка: DHL/UPS/FEDEX/EMS и наша собственная экспресс-линия;

- По воздуху, морю или суше;

- Порт отправки: Шанхай, Нинбо, Циндао, Тяньцзинь или по вашему запросу.

Свяжитесь с поставщиками рулонной нержавеющей стали.

- Вы можете легко заказать рулоны нержавеющей стали любого размера и количества онлайн.

Кроме того, наша дружелюбная команда по продажам будет рада принять ваш заказ. Просто позвоните +86 13382898899 или напишите по электронной почте Daxunhejin@gmail, и мы свяжемся с вами как можно скорее.

Пожалуйста, заполните форму на странице «Связаться с нами» или позвоните нашему менеджеру по продажам по телефону «+86 13382898899», мы свяжемся с вами как можно скорее. Наш WhatsApp в сети, а электронная почта ([email protected]) будет проверена в течение 6 часов. На каждый запрос или сообщение будет дан оперативный ответ. Кроме того, мы каждую неделю делимся рыночной информацией с нашими клиентами

Образцы могут быть предоставлены бесплатно, но расходы на доставку несет заказчик, и они будут возвращены после сотрудничества.

Мы экспортируем продукцию в более чем 42 страны, такие как Канада, Чили, Кувейт, Германия, Южная Корея, Саудовская Аравия, Сингапур и т. д.

Наш минимальный заказ составляет 1 тонну для рулона нержавеющей стали марки 304.

У нас есть полная организация от закупки сырья до обработки и организации отгрузки. Во всей цепочке документальные люди и QC будут искать и проверять его по точным требованиям. Инспекция третьей стороны приветствуется.

Пробные заказы могут быть доставлены в течение недели. Для обычных заказов это занимает около двух недель.