2507 пруток нержавеющий

Ведущие поставщики прутков и стержней из нержавеющей стали в Китае

-

- Daxun Alloy предлагает Duplex 2507 в форме круглых и плоских прутков.

- Доступно в холоднокатаном и горячекатаном вариантах.

- Состав: 25% хрома, 4% молибдена, 7% никеля.

- Высокая прочность и отличная коррозионная стойкость

- Используется в оборудовании для химической обработки, нефтехимии и морской воды.

- Устойчив к хлоридному коррозионному растрескиванию под напряжением

- Хорошие тепловые свойства, включая низкое тепловое расширение, что делает его пригодным для использования в условиях высоких температур.

Мировой лидер в сфере услуг по изготовлению прутков из нержавеющей стали и круглого проката

ОБЩИЕ СВОЙСТВА

Duplex 2507 (UNS S32750) — это пруток из супердуплексной нержавеющей стали. В его состав входит 25% хрома, 4% молибдена и 7% никеля. Этот сплав отлично подходит для сложных условий, обеспечивая исключительную прочность и коррозионную стойкость. Это идеальный выбор для химической переработки и нефтехимической промышленности. Оборудование для морской воды также выигрывает от его исключительных свойств. Duplex 2507 устойчив к хлоридному коррозионному растрескиванию под напряжением. Его термические свойства впечатляют, высокая проводимость и низкое тепловое расширение делают его идеальным для высокотемпературных применений. Уникальное сочетание элементов сплава обеспечивает первоклассную коррозионную стойкость. Для жестких условий, требующих как прочности, так и долговечности, Duplex 2507 обеспечивает.

Наша сеть сервисных центров имеет на складе прутки из нержавеющей стали для быстрой и готовой поставки прутков обычных размеров и сплавов. Мы также производим прутки из нержавеющей стали по индивидуальным размерам и можем организовать графики инвентаризации для быстрого оборота в установленные сроки, если объемы ниже заводских минимумов. Daxun Alloys имеет на складе круглые прутки из нержавеющей стали диаметром от 1/16″ до 26″. Круглые прутки доступны почти из всех марок нержавеющей стали, включая 302, 303, 304/L, 309/S, 310/S, 316/L, 317/L, 321, 321/H, 347, 347H, 410, 416, 420, 440C, 17-4PH, Duplex 2205 и Alloy 20. Закаленные круглые прутки из нержавеющей стали предлагаются в 17-4PH, закалке H900 (по запросу), H1025, H1150, Double H1150 и H1150M. Другие закаленные закалки могут быть изготовлены по запросу. Мы поставляем следующие виды нержавеющей стали 400-й серии: 410, 430 и 416. Мы также поставляем прецизионные и подшипниковые прутки из нержавеющей стали 303, 304 и 316/L. Большая часть нашего инвентаря состоит из наших уникальных сортов обработанных прутков: прутков из нержавеющей стали, которые плавятся в соответствии со стандартами для повышения обрабатываемости и снижения общей стоимости компонента. Наше оборудование для обработки прутков из нержавеющей стали позволяет Daxun Alloys производить продукцию в точном соответствии с техническими требованиями наших клиентов.

Данные

- Параметр

- Ингредиенты

- Механические свойства

- ФИЗИЧЕСКИЕ СВОЙСТВА

- Все эквивалентно

- Типы

| Параметры продукта: стержень из нержавеющей стали | |

| Технические характеристики | ГОСТ 5949-75,ГОСТ 2590-2006,ГОСТ 5582-75 ASTM A276, ASME SA276 / ASTM A479 ASME SA479 |

| Размеры | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Дуплекс 2507- S32750 Круглые прутки | Наружный диаметр в диапазоне от 4 мм до 500 мм |

| Дуплекс 2507- S32750 Круглые прутки | Внешний диаметр в диапазоне от 4 мм до 100 мм |

| Дуплекс 2507- S32750 Круглые прутки | 18 мм – 57 мм (от 11/16″ до 2-3/4″) |

| Заканчивать | Черный, полированный, грубая обработка, отделка № 4, матовая отделка, отделка BA |

| Длина | От 1 до 6 метров, индивидуальная длина отрезка |

| Форма | Круг, квадрат, шестигранник (A/F), прямоугольник, заготовка, слиток, поковка и т. д. |

| Оценка | Супер Дуплекс 2507 |

| Обозначение UNS | S32750 |

| Углерод (C) Макс. | 0,03 |

| Марганец (Mn) Макс. | 1.2 |

| Фосфор (P) Макс. | 0,035 |

| Сера (S) Макс. | 0,02 |

| Кремний (Si) Макс. | 0,8 |

| Хром (Cr) | 24,0–26,0 |

| Никель (Ni) | 6,0–8,0 |

| Молибден (Mo) | 3,0–5,0 |

| Азот (N) | 0,24–0,32 |

| Железо (Fe) | Бал. |

| Медь (Cu) | 0,5 |

| Другие элементы | — |

| Физические свойства супердуплексных сплавов 2507 в отожженном состоянии при температуре от -20°F до +100°F | ||||||||||||||

| Предел прочности | Предел текучести | |||||||||||||

| Сплав | Обозначение UNS | Спец. | пси | МПа | кси | пси | МПа | кси | Удлинение в 2 дюйма (мин.) % | Требуемый размер зерна | Макс. твердость | Модуль упругости (x106 фунтов на кв. дюйм) | Средний коэффициент теплового расширения (дюйм./дюйм./°F x 10-6) | Теплопроводность (БТЕ-дюйм/ фут2-ч-°F) |

| Супер Дуплекс 2507 | S32950 | А789, А790 | 100,000 | 690 | 100 | 70,000 | 485 | 70 | 20 | — | 30,5 Рс | — | — | — |

| Супер Дуплекс 2507 | S32750 | А789, А790 | 116,000 | 800 | 116 | 80,000 | 550 | 80 | 15 | — | 32 Рс | 27.5 | 7.2 | 98 |

| Плотность, фунт/дюйм3 | 0,28 |

| Модуль упругости, фунт/кв. дюйм | 29.0x 106 |

| Коэффициент теплового расширения, 68-212˚F, /˚F | 7,5 х 10-6 |

| Теплопроводность, БТЕ/фут·ч˚F | 8 |

| Удельная теплоемкость, БТЕ/фунт ˚F | 0,12 |

| Удельное электрическое сопротивление, мкОм-дюйм | 31,5 |

| Ассортимент продукции Super Duplex 2507 | |||

| Сплав | Обозначение UNS | Веркстофф NR. | Технические характеристики* |

| Супер Дуплекс 2507 | S32750 | 1.4410 | А/СА789, А/СА790 |

| Нержавеющая сталь 2507/S32750, блестящая полоса | SS 2507/S32750 Яркая полоса |

| 2507/S32750 SS Светлая полоса | |

| Нержавеющая сталь 2507/S32750, блестящая полоса | |

| UNS S2507/S3275000 SS Светлая полоса | |

| ВЕРКСТОФФ Н.Р. 1.4410 Яркая полоса | |

| ASTM A276 2507/S32750 нержавеющая сталь блестящий пруток | |

| Шестигранный стержень из нержавеющей стали 2507/S32750 | Шестигранный стержень SS 2507/S32750 |

| 2507/S32750 Шестигранный стержень из нержавеющей стали | |

| Шестигранный стержень из нержавеющей стали 2507/S32750 | |

| Шестигранный стержень из нержавеющей стали UNS S2507/S3275000 | |

| Шестигранный стержень из нержавеющей стали ASTM A276 2507/S32750 | |

| Квадратный пруток из нержавеющей стали 2507/S32750 | SS 2507/S32750 Квадратный пруток |

| 2507/S32750 Квадратные прутки из нержавеющей стали | |

| 2507/S32750 Квадратный пруток из нержавеющей стали | |

| UNS S2507/S3275000 квадратный пруток из нержавеющей стали | |

| ВЕРКСТОФФ Н.Р. 1.4410 Квадратный стержень | |

| Квадратные прутки из нержавеющей стали ASTM A479 2507/S32750 | |

| Прямоугольный пруток из нержавеющей стали 2507/S32750 | SS 2507/S32750 Прямоугольный брус |

| 2507/S32750 Прямоугольные стержни из нержавеющей стали | |

| 2507/S32750 Прямоугольный пруток из нержавеющей стали | |

| Прямоугольные стержни из нержавеющей стали UNS S2507/S3275000 | |

| ВЕРКСТОФФ Н.Р. 1.4410 Прямоугольный стержень | |

| Прямоугольный пруток из нержавеющей стали ASTM A276 2507/S32750 | |

| Плоские прутки из нержавеющей стали 2507/S32750 | SS 2507/S32750 Плоский пруток |

| 2507/S32750 Плоские прутки из нержавеющей стали | |

| Плоские прутки из нержавеющей стали 2507/S32750 | |

| Плоские прутки из нержавеющей стали UNS S2507/S3275000 | |

| ВЕРКСТОФФ Н.Р. 1.4410 Плоские стержни | |

| ASTM A276 2507/S32750 Плоские прутки из нержавеющей стали | |

| Полированный брусок из нержавеющей стали 2507/S32750 | SS 2507/S32750 Полированный брусок |

| 2507/S32750 Полированные прутки из нержавеющей стали | |

| 2507/S32750 Полированный брус из нержавеющей стали | |

| Полированные прутки из нержавеющей стали UNS S2507/S3275000 | |

| ВЕРКСТОФФ Н.Р. 1.4410 Полированный стержень | |

| Полированный пруток из нержавеющей стали ASTM A476 2507/S32750 | |

| Резьбовой стержень из нержавеющей стали 2507/S32750 | Резьбовой стержень SS 2507/S32750 |

| Резьбовые стержни из нержавеющей стали 2507/S32750 | |

| 2507/S32750 Резьбовой стержень из нержавеющей стали | |

| Резьбовой стержень из нержавеющей стали UNS S2507/S3275000 | |

| ВЕРКСТОФФ Н.Р. 1.4410 Резьбовой стержень | |

| Резьбовой стержень из нержавеющей стали ASTM A276 2507/S32750 |

Выбирайте Daxun и сделайте своих клиентов довольными.

Быстрый ответ

Мы обеспечиваем своевременную и быструю доставку прутков из нержавеющей стали 2507 для клиентов с срочными потребностями. За скоростью стоит системная поддержка от информационного потока до логистики и движения капитала. Например, с точки зрения информационного потока, данные о заказах Daxun передаются в логистическую систему в режиме реального времени, и данные бесшовно связаны;

Преимущества Даксуна

- Разновидности: Мы предлагаем широкий ассортимент размеров и марок, включая серии 300, 400, 600 и другие.

- Гибкость: независимо от того, нужны ли вам горячекатаные или холоднотянутые прутки, длина наших прутков из нержавеющей стали подбирается в соответствии с требованиями вашего конкретного проекта.

- Стандарты качества: стержень из нержавеющей стали 2507 соответствует строгим стандартам ASTM, ISO9001, GB, NSF/ANSI, что гарантирует надежность и производительность.

- Индивидуальные заказы: Ищете специальные размеры прутков из нержавеющей стали? Мы предлагаем различные варианты изготовления прутков из нержавеющей стали по конкурентоспособным ценам и с удобным онлайн-заказом.

Упаковка стержня из нержавеющей стали 2507

Мы уделяем внимание каждому процессу, чтобы гарантировать качество. Упаковка круглых прутков 2507, которую мы обычно применяем, заключается в упаковке круглых прутков из нержавеющей стали в экологически чистые пластиковые пакеты, а затем в деревянные ящики или деревянные поддоны, не прошедшие фумигацию. Также можно обсудить индивидуальную упаковку, например OEM. Мы предоставляем почти все, чтобы удовлетворить ваши требования к упаковке круглых прутков. Мы придаем большое значение упаковке. Круглые прутки упаковываются в деревянные гофрированные коробки, обернутые пластиковой упаковкой и пузырчатой пленкой снаружи.

Качество, доставка, проверка

- Daxun также проводит несколько испытаний на обеспечение качества. Эти испытания включают испытание на сплющивание, испытание на питтинг и сопротивление, механическое испытание, испытание на твердость, положительную идентификацию материала, испытание на расширение и т. д. Все эти испытания гарантируют, что материал подходит для требуемого применения.

- В процессе производства мы измеряем диаметр, толщину и поверхность изделия. Наш стандартный срок поставки составляет 7-15 дней, за исключением некоторых изделий специального размера, срок поставки увеличивается до 20 дней.

Срок поставки строго соответствует договору. - Поддержка сторонних агентств-клиентов при посещении завода для проведения инспекции

- Предоставляем бесплатные образцы клиентам для тестирования

- Поддержка инспекции завода на месте или видеоинспекции

Техническая поддержка

Если вам нужна дополнительная техническая помощь, наш местный металлург и знающий персонал будут рады помочь. Кроме того, Daxun может похвастаться сертифицированной испытательной лабораторией — первой в отрасли многометаллического и пластикового инвентаря. Это, по нашему мнению, демонстрирует нашу непоколебимую преданность качеству и нашу философию как поставщика полного спектра услуг.

Информация для заказа стержня из нержавеющей стали 2507

2507 Круглый пруток Заказы на закупку должны включать количество, класс PSL, тип или категорию, ссылку API5L, диаметр, отделку поверхности, длину и любые применимые приложения или дополнительные требования, связанные с химическим составом, механическими свойствами, термической обработкой, дополнительными испытаниями, производственным процессом, отделкой поверхности или обработкой концов. Прутки подвергаются светлому отжигу на твердый раствор.

Характеристики стержня из нержавеющей стали 2507/S32750

Daxun Alloy Позвольте вашему бренду быстро улучшиться

- Галерея

- Состояние доставки

- Возрастная закалка

| Выбор штата доставки | Состояние поверхности |

| Кованый | Черный |

| Полированный | |

| Горячекатаный | Черный |

| Полированный | |

| Яркий | |

| Маринованный | |

| Холоднотянутый | Полированный |

| Яркий | |

| Примечание: | |

| 1. Если вам требуется другой штат доставки, чем указанный выше, пожалуйста, уточните у нас. | |

| 2. В случае возникновения каких-либо вопросов или заказов, пожалуйста, сообщите нам о любых дополнительных требованиях, не указанных здесь. | |

| Материал в состоянии, подвергнутом отжигу на твердый раствор, может быть подвергнут старению следующим образом: *Обозначает двойное старение | ||||||||||||

| Состояние | Н900 (Н480) | Н925 (Н495) | Н1025 (Н550) | Н1075 (Н580) | Н1100 (Н595) | Н1150 (Н620) | Н1150М (Н620М)* | Плюс | H1150D (H620D)* | Плюс | ||

| Нагреть до | ±15oF | 900oF | 925 градус по Фаренгейту | 1025oF | 1075oF | 1100oF | 1150oF | 1400oF | 1150oF | 1150oF | 1150oF | |

| ±9oC | 480℃ | 495°С | 550℃ | 580℃ | 595°С | 620℃ | 760℃ | 620℃ | 620℃ | 620℃ | ||

| Удерживать в течение нескольких часов | 1 | 4 | 4 | 4 | 4 | 4 | 2 | 4 | 4 | 4 | ||

| Охлаждение до температуры ниже | Воздух | Воздух | Воздух | Воздух | Воздух | Воздух | Воздух | Воздух | Воздух | Воздух | ||

| 90oF (32oC) | ||||||||||||

Типы стержней из нержавеющей стали 2507/S32750 (6)

Информация доступна для ознакомления и скачивания

Производство прутков из нержавеющей стали

Daxun — надежный производитель прутков и стержней из нержавеющей стали.

Как профессиональный производитель, Daxun гарантирует, что вся производимая нами продукция отличается высоким качеством. Поэтому мы гарантируем, что все нержавеющие прутки сертифицированы по стандартам ISO9001, SGS, CE, OQC

Последние горячие проекты и продукты

Ведущие поставщики прутков и стержней из нержавеющей стали в Китае

Стержень и планка из нержавеющей стали DUPLEX 2507

-

В настоящее время в ассортименте Daxun Alloys Stainless Steels имеются круглые и плоские прутки Duplex 2507, которые доступны как в холоднокатаном, так и в горячекатаном виде. Этот пруток из супердуплексной нержавеющей стали содержит 25% хрома, 4% молибдена и 7% никеля. Сплав подходит для применений, требующих высокой прочности и коррозионной стойкости, таких как химическая обработка, нефтехимическое и морское оборудование. Сталь обладает высокой стойкостью к хлоридному коррозионному растрескиванию под напряжением, хорошей теплопроводностью и низким коэффициентом теплового расширения. Высокое содержание хрома, молибдена и никеля обеспечивает отличную стойкость к точечной, щелевой и общей коррозии.

Приложения

-

- Нефть и газ:

- Морские платформы, теплообменники, системы водоснабжения

- Системы пожаротушения, закачки и балластной воды

- Химическая обработка:

- Теплообменники, сосуды и трубопроводы

- Опреснение:

- Системы обратного осмоса высокого давления и трубопроводы морской воды

- Механические и структурные компоненты:

- Высокопрочные, коррозионно-стойкие детали

- Энергетическая промышленность:

- Системы FGD, системы скрубберов, абсорбционные башни

- Воздуховоды и трубопроводы

- Направления экспорта: Наши круглые прутки из нержавеющей стали марки 2507 экспортируются в различные страны, включая Коста-Рику и Южную Корею, что подчеркивает наш глобальный охват и международный спрос на нашу высококачественную продукцию.

Стандарты

- АСТМ/АСМЕ…………. A240 – UNS S32750

ЕВРОНОРМ………… 1.4410 – X2 Cr Ni MoN 25.7.4

AFNOR……………….. Z3 CN 25.06 Az

КОРРОЗИОННАЯ УСТОЙЧИВОСТЬ

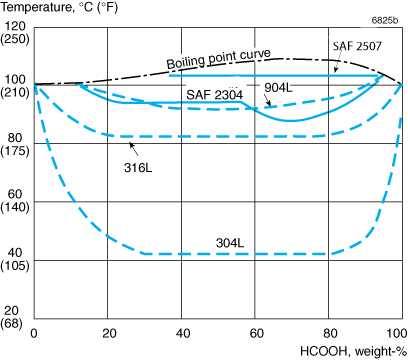

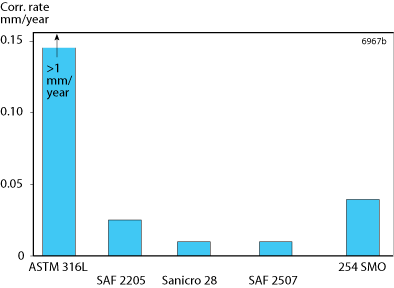

Общая коррозия

SAF 2507™ демонстрирует отличную устойчивость к общей коррозии. Он очень устойчив к коррозии, вызываемой органическими кислотами. В 10% муравьиной и 50% уксусной кислоте он испытывает менее 0,05 мм/год. Это превосходит ASTM 316L, у которого скорость коррозии превышает 0,2 мм/год. SAF 2507™ сохраняет устойчивость даже в загрязненных кислотах (см. рисунки 5 и 6).

Рисунок 4. Диаграмма изокоррозии в муравьиной кислоте. Кривые представляют скорость коррозии 0,1 мм/год (4 мпг) в застойном тестовом растворе.

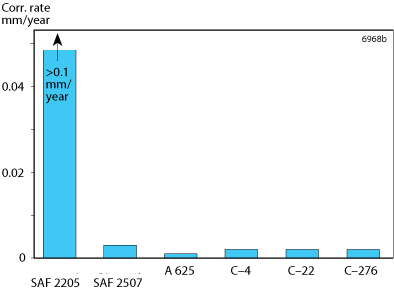

Figure 5. Corrosion rate of various alloys in 80% acetic acid with 2000 ppm chloride ions at 90°C.

Figure 6. Corrosion rate of various alloys in concentrated acetic acid with 200 ppm chloride ions.

SAF 2507™ exhibits excellent resistance to general corrosion. It is highly resistant to corrosion by organic acids. In 10% formic and 50% acetic acid, it experiences less than 0.05 mm/year. This outperforms ASTM 316L, which has a corrosion rate higher than 0.2 mm/year. SAF 2507™ remains resistant even in contaminated acids (see Figures 5 and 6).

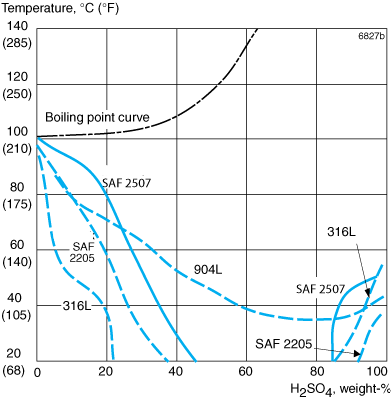

Figure 7. Isocorrosion diagram in naturally aerated sulfuric acid. The curves represent a corrosion rate of 0.1 mm/year (4 mpy) in a stagnant test solution.

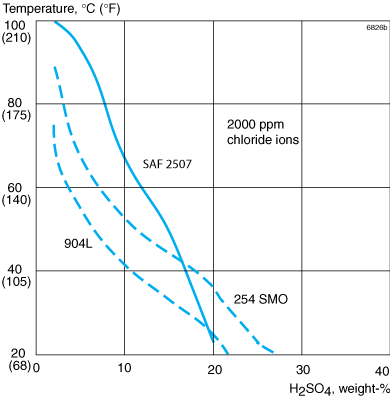

Figure 8. Isocorrosion diagram, 0.1 mm/year (4 mpy) in a naturally aerated sulfuric acid containing 2000 ppm chloride ions.

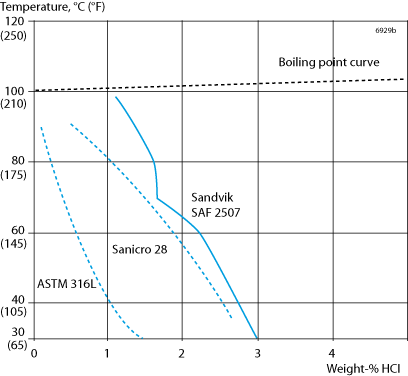

Figure 9. Isocorrosion diagram in hydrochloric acid. The curves represent a corrosion rate of 0.1 mm/year (4 mpy) in stagnant test solution.

SAF 2507™ excels in resisting inorganic acids, often surpassing high-alloy austenitic stainless steels. Isocorrosion diagrams reveal its strength against sulfuric and hydrochloric acids. The alloy thrives in terephthalic acid plants, proving its exceptional resistance. It offers a competitive edge over high-alloyed austenitics and nickel alloys. In environments where standard austenitic stainless steels falter, SAF 2507™ stands strong. Its performance in harsh chemical settings makes it a top choice. Industries dealing with corrosive acids find SAF 2507™ to be a reliable solution. The alloy’s versatility shines in various concentration ranges of inorganic acids.

To ensure the highest quality, all products undergo rigorous testing and third-party inspection before packaging.

Pitting and crevice corrosion

Stainless steel’s resistance to pitting and crevice corrosion hinges on key elements. Chromium, molybdenum, and nitrogen content significantly impact its performance. The manufacturing process plays a vital role in corrosion resistance. Welding and other fabrication methods can affect the steel’s durability. SAF 2507™’s composition is optimized for superior corrosion resistance. Its high alloy content ensures robust protection against localized corrosion. Proper manufacturing techniques enhance the material’s service life. In challenging environments, SAF 2507™ stands out for its resilience.

The PRE (Pitting Resistance Equivalent) number is a parameter used to compare the resistance to pitting in chloride environments. It is defined as PRE = %Cr + 3.3 x %Mo + 16 x %N (in weight-%). In duplex stainless steels, the pitting corrosion resistance is determined by the PRE value in both the ferrite and austenite phases. The phase with the lowest PRE value limits the actual pitting corrosion resistance. SAF 2507™ has been carefully balanced to achieve equal PRE values in both phases.

SAF 2507™ seamless tubes boast a minimum PRE value of 42.5. This surpasses other 25Cr duplex steels, like UNS S31260, significantly. The ASTM G48 test rigorously evaluates pitting and crevice corrosion resistance. It exposes steel to harsh 6% FeCI3 solutions, with and without crevices. A modified version increases temperature until pitting occurs. Figure 11 displays critical pitting and crevice temperatures from this test. Potentiostatic tests reveal performance in varied chloride and acidic environments. These tests use high potentials, exceeding typical seawater conditions. As a result, critical temperatures are lower than in most practical applications. SAF 2507™ consistently demonstrates superior corrosion resistance in these demanding tests.

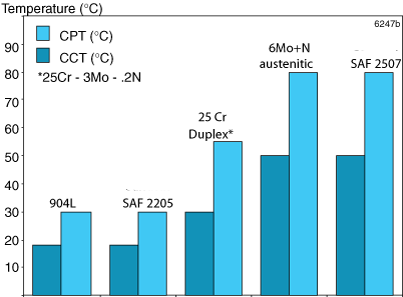

Figure 10. Critical pitting and crevice temperatures in 6% FeCl3, 24h (similar to ASTM G48).

SAF 2507™ and 6Mo+N show similar pitting resistance in 6% FeCl3. Tests in natural seawater evaluated critical crevice corrosion temperatures. The potential applied was 150 mV vs SCE, with temperature increases every 24 hours. Results are presented in the accompanying table. Crevice corrosion propagation rates were also measured at different temperatures. SAF 2507™ demonstrated remarkably low propagation rates compared to 6Mo+N alloy. Its rates were approximately ten times lower, showcasing superior corrosion resistance. This performance highlights SAF 2507™’s effectiveness in challenging marine environments. The data underscores its suitability for applications requiring exceptional corrosion resistance.

| Alloy | CCT (°C) |

|---|---|

| SAF 2507 | 64 |

| 6Mo+N | 61 |

In these tests the propagation rates of initiated crevice corrosion attacks, at 15-50°C (59-122°F) and an applied potential of 150 mV vs SCE were also determined. These were found to be around ten times lower for SAF™ 2507 than for the 6Mo+N alloy.

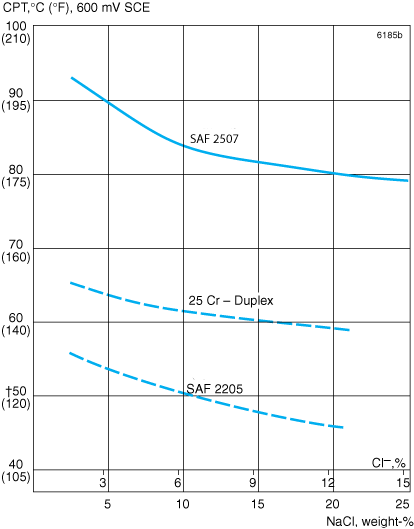

Figure 11. Critical pitting temperatures (CPT) at varying concentrations of sodium chloride, from 3 to 25%

The CPT values were determined potentiostatically at +600 mV SCE with surfaces ground using 600 grit paper.

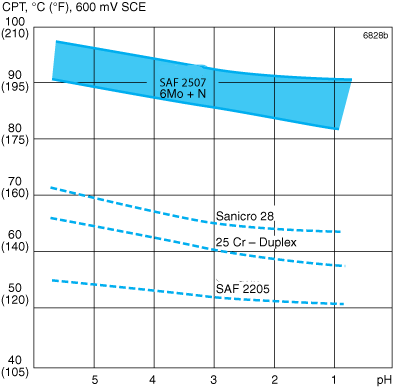

Figure 12 illustrates the critical pitting temperatures (CPT) in 3% NaCl solution with varying pH levels. These values were also determined potentiostatically at +600 mV SCE with surfaces ground using 600 grit paper.

SAF 2507™ showcases exceptional corrosion resistance in oxidizing chloride solutions. Tests in ‘Green death’ and ‘Yellow death’ solutions reveal its strength. The table presents critical pitting temperatures (CPT) for various alloys. SAF 2507™’s performance matches that of nickel alloy UNS N06625. This data correlates well with alloy rankings for reheater tubes. Flue gas desulfurization systems benefit from such corrosion-resistant materials. The test results highlight SAF 2507™’s versatility in harsh chemical environments. Its high CPT values indicate superior protection against pitting corrosion. This makes SAF 2507™ a top choice for demanding industrial applications. The alloy’s resistance to these aggressive solutions is truly impressive.

| Alloy | Critical pitting temperature (CPT), °C ‘Green death’ |

‘Yellow death’ |

|---|---|---|

| SAF™ 2507 | 72.5 | >90 |

| 6Mo+N | 70 | >90 |

| UNS N06625 | 67.5 | >90 |

| ASTM 316 | <25 | 20 |

Stress corrosion cracking

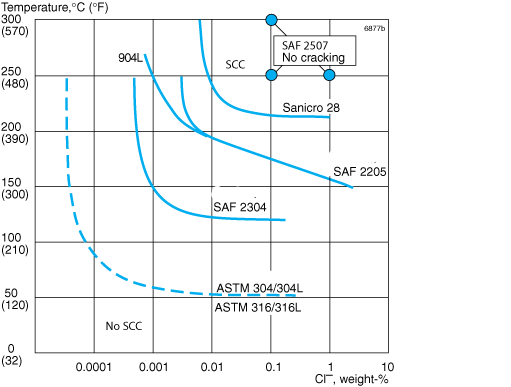

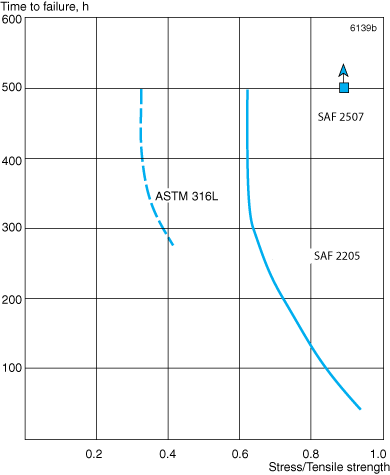

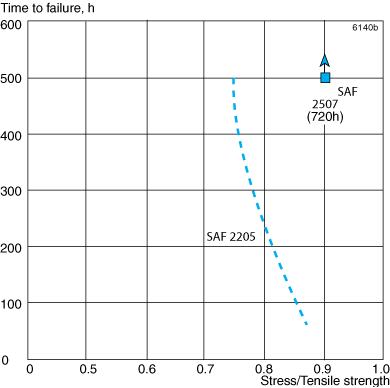

SAF 2507™ shows remarkable resistance to chloride-induced stress corrosion cracking (SCC). Figure 13 displays its performance in high-temperature chloride solutions. The alloy resists SCC in up to 1000 ppm Cl⁻ at 300°C. It also withstands 10000 ppm Cl⁻ at 250°C without cracking. U-bend tests in hot brine further prove its durability. SAF 2507™ maintains integrity in 40% CaCl₂ at high temperatures. Its threshold stress exceeds 90% of tensile strength for both base metal and welds. Figure 14 reveals its superiority in acidified conditions compared to SAF 2205™. Even in boiling 45% MgCl₂, SAF 2507™ retains half its proof strength. These results underscore SAF 2507™’s exceptional SCC resistance across various harsh environments, partly due to its low thermal expansion.

Figure 13. SCC resistance in oxygen-bearing (abt. 8 ppm) neutral chloride solutions. Testing time 1000 hours. Applied stress equal to proof strength at testing temperature.

Figure 14. Results of SCC tests with constant load in 40% CaCl2, pH=1.5, at 100 °C (210°F) with aerated test solution.

Figure 15. Constant load SCC tests in NACE solution at room temperature (NACE TM 0177).

Figure 13 highlights SAF 2507™’s stress corrosion cracking resistance in oxygen-rich chloride solutions. Tests ran for 1000 hours under high stress conditions. The alloy demonstrated impressive resilience across various temperatures and chloride concentrations. Figure 14 showcases SAF 2507™’s performance in acidic, hot calcium chloride. These tests reveal the alloy’s strength in harsh chemical environments. Figure 15 presents results from NACE solution tests at room temperature. SAF 2507™ showed no signs of cracking, regardless of applied stress. This exceptional performance underscores its suitability for demanding applications. The data consistently proves SAF 2507™’s superior resistance to stress corrosion cracking. These results make SAF 2507™ a top choice for industries facing corrosive challenges.

Hydrogen sulfide environments pose unique challenges for stainless steels. SAF 2507™ shows resilience in these conditions below 60°C (140°F). Acidity and chloride content influence the corrosivity of such solutions. Interestingly, ferritic stainless steels are more vulnerable than austenitic types. ISO 15156/NACE MR 0175 approves SAF 2507™ for sour environments. It’s suitable for oil and gas production up to 450°F (232°C). This applies when hydrogen sulfide partial pressure stays below 3 psi (0.20 bar). For sour petroleum refining, SAF 2507™ meets NACE MR0103 standards. The alloy must be solution annealed, rapidly cooled, and maintain a maximum hardness of 32 HRC. These specifications highlight SAF 2507™’s versatility in challenging industrial applications.

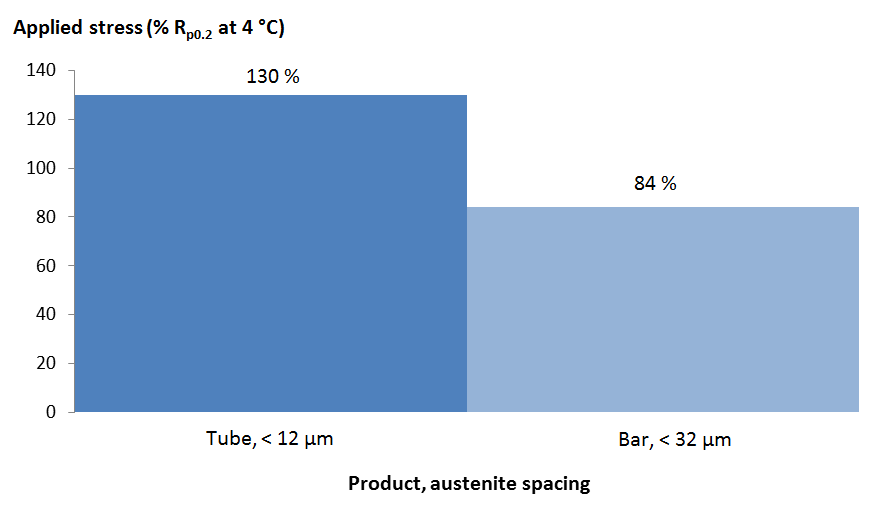

Hydrogen Induced Stress Cracking (HISC)

Hydrogen Induced Stress Cracking (HISC) poses a risk in subsea environments. It affects cathodically protected steel structures under high tensile stress. SAF 2507™, when connected to protected carbon steels, may face HISC risks. Low electrochemical potentials generate atomic hydrogen on steel surfaces. This hydrogen can diffuse into the metal, causing embrittlement. Ferrite phases in super duplex steels allow faster hydrogen diffusion. This makes SAF 2507™ more susceptible to HISC than austenitic steels. High mechanical stress exacerbates the problem. It increases hydrogen diffusion and crack propagation. Understanding these factors is crucial for safe subsea applications. Proper design and stress management can mitigate HISC risks in SAF 2507™ installations.

Super duplex stainless steels show unique HISC behavior. Cracks in SAF 2507™ propagate through the embrittled ferrite phase. They typically stop at ferrite-austenite boundaries. Austenite spacing plays a crucial role in HISC susceptibility. Coarser grains increase the risk of cracking. DNV RP-F112 recommends austenite spacing below 30 μm. Alleima’s tests confirm this reduces HISC tendency. Cold pilgered and solution annealed tubes perform exceptionally well. With 5-15 μm austenite spacing, they resist HISC up to 130% yield strength. Figure 16 shows how austenite spacing affects acceptable stress levels. This data helps engineers design safer subsea structures using SAF 2507™. Proper processing ensures optimal microstructure for HISC resistance.

The acceptable stress without HISC occurring for products with different austenite spacing is illustrated in figure 16.

Intergranular corrosion

SAF 2507™ shows excellent resistance to intergranular corrosion. Its balanced composition allows quick austenite reformation in weld-affected zones. This microstructure ensures strong corrosion resistance. The alloy passes the ASTM A262 Practice E (Strauss test) without issues.

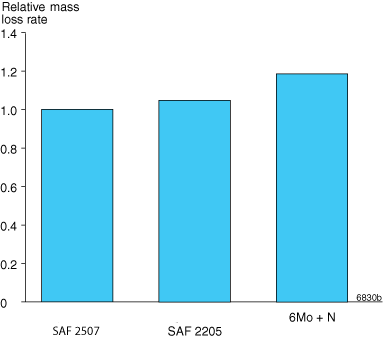

Erosion corrosion

SAF 2507™ excels in erosion corrosion resistance. Its mechanical properties and corrosion resistance contribute to this strength. Tests in sand-containing media prove its superiority over austenitic stainless steels. Figure 17 compares mass loss rates of different alloys. SAF 2507™ outperforms SAF 2205™ and 6Mo+N austenitic steel. These tests used synthetic seawater with silica sand at various velocities. The results highlight SAF 2507™’s durability in erosive environments. This makes it ideal for applications facing both corrosion and erosion challenges.

Figure 17. Relative mass loss rate after testing of the resistance against erosion corrosion.

Corrosion fatigue

SAF 2507™ demonstrates exceptional resistance to corrosion fatigue. Its high tensile strength contributes to an impressive fatigue limit. The alloy excels in both standard fatigue and corrosion fatigue scenarios. SAF 2507™’s superior mechanical properties explain its high fatigue strength. Rigorous testing in corrosive environments confirms its corrosion fatigue resistance. This dual strength makes SAF 2507™ ideal for cyclically loaded structures. Industries dealing with harsh, corrosive conditions benefit from its resilience. The alloy’s performance ensures longer service life in demanding applications. SAF 2507™ stands out among duplex stainless steels for its fatigue resistance.

PROCESSING

2507 super duplex stainless steel can be processed using both hot and cold forming techniques. Each method requires specific considerations to ensure optimal results.

Hot Forming: 2507 can be hot formed at temperatures between 1875°F and 2250°F. After hot forming, a solution anneal should be performed at a minimum temperature of 1925°F. This is followed by a rapid air or water quench to maintain the desired properties.

Cold Forming: Cold working of 2507 super duplex steel is possible using most typical stainless steel forming processes. However, due to its higher yield strength and lower ductility compared to austenitic steels, some adjustments may be necessary. Due to its low thermal expansion, 2507 super duplex steel maintains dimensional stability during cold forming processes.

Fabricators may need to use higher forming forces, larger bend radii, and allow for greater springback when cold forming 2507. Deep drawing, stretching, and other similar processes are more challenging for 2507 than for austenitic stainless steels.

When the forming process requires more than 10% cold deformation, solution annealing and quenching are recommended to restore the material’s properties.

Heat TreatmentHeat treatment for 2507 consists of solution annealing and quenching after hot or cold forming. Solution annealing should be performed at a minimum temperature of 1925°F. Annealing should be followed immediately by a rapid air or water quench. Heat treated items that are pickled and rinsed have excellent corrosion resistance. Savoy Piping Inc. is a leading supplier of 2507 Super Duplex Round Bars, known for their high quality and excellent customer service.

Welding2507 is weldable and can be joined to other materials using SMAW, GTAW, PAW, FCW, or SAW. When welding 2507, a 2507/P100 filler metal is recommended to ensure proper duplex weld construction.

2507 does not require preheating except to prevent condensation on cold metal. Interpass welding temperatures should not exceed 300°F or weld integrity will be compromised. To maximize corrosion resistance, root protection should be applied using either argon or 90% N2/10% H2 purge gas. The latter provides higher corrosion resistance.

2507-S32750 grade stainless steel round bars

Stainless steel round bars can be easily ordered in a wide range of sizes. Simply select the grade of steel you require and we will provide bars in lengths ranging from 500mm to 6 meters, and diameters ranging from 3mm to 500mm. We even give you the option of ordering in metric or imperial sizes. If you want something that is not a standard size, that’s no problem. We offer unlimited free cuts to length. Using state-of-the-art bandsaws to ensure accuracy and repeatability, we can precisely meet your requirements every time. Just let us know when ordering.

Wide Range of Sizes to Choose From

Daxun Alloys offers an extensive selection of stainless steel round bar sizes. Choose your preferred grade and customize your order. We provide lengths from 500mm to 6 meters. Diameters range from 3mm to 500mm. You can order in metric or imperial units for your convenience. Need a non-standard size? No problem. We offer unlimited free cuts to length. Our state-of-the-art bandsaws ensure precise, repeatable results. We’ll meet your exact specifications every time. Just specify your requirements when ordering. Daxun’s flexibility caters to diverse project needs. Our cutting service saves you time and effort. Experience hassle-free ordering with Daxun Alloys’ custom sizing options.

Contact Your Stainless Steel Round Bar Supplier

Daxun Alloy — ваш надежный поставщик высококачественных круглых прутков из нержавеющей стали. Мы обслуживаем как разовые заказы, так и долгосрочные планы по поставкам. Наш разнообразный выбор марок отвечает различным производственным потребностям. Усильте свое производство с помощью превосходных металлических решений Daxun. Оформить заказ легко через наш удобный веб-сайт. Предпочитаете персональную помощь? Позвоните в нашу команду по продажам по телефону +8613382898899. По вопросам пишите нам по адресу [email protected] . Мы готовы адаптировать решения под ваши конкретные требования. Выбирайте Daxun за надежность, качество и ориентированное на клиента обслуживание. Свяжитесь с нами сегодня, чтобы улучшить свой производственный процесс с помощью круглых прутков из нержавеющей стали премиум-класса.

Мы можем предоставить вам образцы прутка из нержавеющей стали 2507 для проверки качества. Образец бесплатный, вы платите только за доставку.

Мы экспортируем продукцию в более чем 42 страны, такие как Канада, Чили, Кувейт, Германия, Южная Корея, Саудовская Аравия, Сингапур и т. д.

Минимальный заказ составляет 1 тонну прутка из нержавеющей стали марки 2507.

Пробные заказы могут быть доставлены в течение недели. Для обычных заказов это занимает около двух недель.