AISI2507 труба нержавеющая

Являясь ведущим поставщиком и экспортером труб из нержавеющей стали в Китае, компания Daxun поставляет трубы из нержавеющей стали по всему миру.

- Марка: AISI 2507/S2507- S32750-04Х25Н7М4БР

- Метод изготовления: горячая прокатка, холодная прокатка, ковка, сварка

- Стандарт: ГОСТ, ASTM, ASME, GB, DIN, JIS, ISO, EN, BS.

- Тип: бесшовная стальная труба общего назначения

- Диаметр: от малого диаметра до большого диаметра трубы

- Толщина: тонкостенная трубка и толстостенная трубка

- Поверхность: травленая AP, полированная, блестящая EP, отожженная BA и т.д.

- Длина: 3000 мм, 6000 мм, 9000 мм и т.д.

Мировой лидер в сфере услуг по производству труб из нержавеющей стали

Daxun Alloys поставляет трубы из нержавеющей стали Duplex 2507 – сварные трубы из нержавеющей стали 2507 – бесшовные трубы из нержавеющей стали 2507 различных форм и размеров, которые соответствуют отраслевым стандартам, таким как ASTM, ASME, EURONORM и AFNOR. Поставщик бесшовных труб ASTM A790, UNS S32750 и UNS S32760, сертифицированный по AS 9100D, из Китая.

Нержавеющая сталь Duplex 2507 – это супердуплексный материал с низким содержанием углерода (до 0,03%), хрома (~25%), никеля (~7%) и молибдена (~4%). Нержавеющая сталь Duplex 2507 предназначена для удовлетворения строгих требований применений, требующих высокой прочности и коррозионной стойкости. К таким применениям относятся химическое технологическое оборудование, нефтехимическая промышленность и оборудование для морской воды. Эта сталь очень устойчива к коррозионному растрескиванию под напряжением, вызванному хлоридами. Благодаря высокому содержанию хрома, молибдена и азота он обеспечивает исключительную стойкость к точечной, щелевой и другим видам коррозии.

Daxun Alloy понимает международные спецификации для супердуплексных бесшовных труб и обладает знаниями о продукте, чтобы поставлять соответствующие товары нашим клиентам. Мы являемся одним из лучших поставщиков супердуплексных труб в Китае благодаря нашим конкурентоспособным ценам, отличному качеству и своевременной доставке.

Супердуплексные бесшовные трубы используются в нефтегазовой промышленности, а также в естественных горизонтальных скважинах с высокой соленостью или скважинах для нагнетания рассола для повышения нефтеотдачи. Супердуплексные трубы также очень прочные и устойчивы к коррозии, усталости и эрозии. Трубы Astm A790 S32750 также устойчивы к равномерной коррозии, вызванной органическими кислотами, такими как уксусная и муравьиная кислоты. Бесшовные трубы из супердуплексной нержавеющей стали Astm A790 демонстрируют высокую теплопроводность и поглощение энергии. Кроме того, полые трубы супердуплекс легко обрабатываются и свариваются. WerkstoffПри нагревании трубы с номером 1.4410 деформируются менее значительно. Деформация супердуплексных труб может привести к неисправным фланцам или соединениям. Трубы 2507 Super Duplex используются в теплообменниках в химической обработке, морской переработке нефти и газа и нефтехимическом производстве. Наши трубы 2507 Super Duplex из нержавеющей стали соответствуют международным стандартам. Наши бесшовные трубы Super Duplex 2507 поставляются в ряд отраслей по всему миру.

- ТЕХНИЧЕСКИЕ ПАРАМЕТРЫ

- ИНГРЕДИЕНТЫ

- МЕХАНИЧЕСКИЕ СВОЙСТВА

- ФИЗИЧЕСКИЕ СВОЙСТВА

- ЭКВИВАЛЕНТНАЯ КЛАССИФИКАЦИЯ

- ТИП ТРУБЫ

| Технические характеристики | ГОСТ 9941-81、ГОСТ 5632-72、ГОСТ 10704-91、 ГОСТ 17375-2001 / ГОСТ 9940-81 、ГОСТ 17375-2001、 ГОСТ 30732-2006、ГОСТ 2590-2006 / ГОСТ 10498-82 ASTM A790/ ASME SA790 |

| Толщина трубы | 0,3 мм – 50 мм |

| Стандарт трубы | Поставщик труб из стали супердуплекс 2507 по стандартам EN, ASTM, ASME AISI, GB, JIS, DIN |

| Наружный диаметр бесшовной трубы Super Duplex 2507 | Размеры до 12” NB/6,00 – 250 мм OD |

| Размер сварной трубы Super Duplex 2507 | 5,0 до 1219,2 мм |

| Размер сварной трубы из стали Super Duplex 2507 | 6,35 – 810 мм наружный диаметр |

| Размер трубы Super Duplex 2507 EFW | 5,0 – 1219,2 мм |

| Толщина стенки трубки из стали Super Duplex 2507 | 0,0020″ – 0,0220″ (возможны индивидуальные толщины стенок) |

| Размер бесшовной трубы Super Duplex 2507 | 15 NB – 508 NB ВНУТР./ 3,35 – 508 мм наружный диаметр, |

| Супердуплекс 2507 Отделка труб и труб | AP (отожженная и травленая), полированная, MF, BA (яркая и отожженная), NO.4, NO.1, BA, 2B, 8K, HL, зеркальная отделка и т. д. |

| Трубы и трубки Swg и Bwg | 12 поворотов, 10 поворотов, 16 поворотов, 14 поворотов, 20 поворотов, 18 поворотов. |

| Трубы сортамента Super Duplex 2507 | СЧ10, СЧ 5, СЧ 80, СЧ 40, , СЧ 160, СЧ 80С, СЧ XS, СЧ XXS |

| Форма трубы и трубки Super Duplex 2507 | Гидравлические, круглые, прямоугольные, полые, змеевики в форме блина, квадратные, спиральные, U-образные, прямые трубы и т. д. |

| Труба Super Duplex 2507 и длина трубки | Стандартная и отрезная длина, одинарная и двойная нерегулярная, |

| Супердуплекс 2507 Труба и тип трубки | Супердуплекс 2507 ERW/бесшовные/сварные/электронная сварка/CDW/сборные/CEW/трубы DOM |

| Труба с добавленной стоимостью услуг | в соответствии с требуемым размером и длиной Вытяжка и расширение, травление Гибка и полировка (электрическая и коммерческая) Отжиг, механическая обработка и т.д. |

| Применение трубки Super Duplex 2507 | Масляная трубка, котел и теплообменник, газовая трубка, жидкостная трубка |

| Труба и конец трубы Super Duplex 2507 | Скошенный конец, гладкий конец, труба с резьбой. |

| Маркировка труб | Все трубы Super Duplex 2507 маркируются следующим образом: стандарт, сорт, толщина, внешний диаметр, номер плавки (или по запросу заказчика), длина |

| Сертификаты испытаний материалов (MTC) | Отчет о 100% радиографическом испытании, сертификат на сырье |

| Сертификаты испытаний материалов (MTC) согласно EN 10204 3.1, EN 10204/3.1B и EN 10204 3.2. | |

| Сертификат испытаний производителя | |

| Форма А для Обобщенной системы преференций (GSP) | |

| Сертификаты фумигации | |

| Отчет о проверке третьей стороной | |

| Схемы термообработки | |

| Трубы Super Duplex 2507 Код HS Коммерческий счет-фактура | |

| Сертификат лабораторных испытаний от утвержденной правительством лаборатории. | |

| Специализируется на | Трубы теплообменника и конденсатора Super Duplex 2507 |

| Капиллярная трубка Super Duplex 2507 и другие нестандартные размеры | |

| Труба большого диаметра Super Duplex 2507 |

| Оценка | Супер Дуплекс 2507 |

| Обозначение UNS | S32750 |

| Углерод (C) Макс. | 0,03 |

| Марганец (Mn) Макс. | 1.2 |

| Фосфор (P) Макс. | 0,035 |

| Сера (S) Макс. | 0,02 |

| Кремний (Si) Макс. | 0,8 |

| Хром (Cr) | 24,0–26,0 |

| Никель (Ni) | 6,0–8,0 |

| Молибден (Mo) | 3,0–5,0 |

| Азот (N) | 0,24–0,32 |

| Железо (Fe) | Бал. |

| Медь (Cu) | 0,5 |

| Другие элементы | — |

| Физические свойства супердуплексных сплавов 2507 в отожженном состоянии при температуре от -20°F до +100°F | ||||||||||||||

| Предел прочности | Предел текучести | |||||||||||||

| Сплав | Обозначение UNS | Спец. | пси | МПа | кси | пси | МПа | кси | Удлинение в 2 дюйма (мин.) % | Требуемый размер зерна | Макс. твердость | Модуль упругости (x106 фунтов на кв. дюйм) | Средний коэффициент теплового расширения (дюйм./дюйм./°F x 10-6) | Теплопроводность (БТЕ-дюйм/ фут2-ч-°F) |

| Супер Дуплекс 2507 | S32950 | А789, А790 | 100,000 | 690 | 100 | 70,000 | 485 | 70 | 20 | — | 30,5 Рс | — | — | — |

| Супер Дуплекс 2507 | S32750 | А789, А790 | 116,000 | 800 | 116 | 80,000 | 550 | 80 | 15 | — | 32 Рс | 27.5 | 7.2 | 98 |

| Плотность, фунт/дюйм3 | 0,28 |

| Модуль упругости, фунт/кв. дюйм | 29.0x 106 |

| Коэффициент теплового расширения, 68-212˚F, /˚F | 7,5 х 10-6 |

| Теплопроводность, БТЕ/фут·ч˚F | 8 |

| Удельная теплоемкость, БТЕ/фунт ˚F | 0,12 |

| Удельное электрическое сопротивление, мкОм-дюйм | 31,5 |

| Ассортимент продукции Super Duplex 2507 | |||

| Сплав | Обозначение UNS | Веркстофф NR. | Технические характеристики* |

| Супер Дуплекс 2507 | S32750 | 1.441 | А/СА789, А/СА790 |

| Выхлопные трубы Super Duplex 2507 | Duplex2507 Супердуплексные круглые трубы |

| Трубы из сплава 2507, сортамент 40 | Трубы из никеля Super Duplex 2507 EFW |

| Материал труб сплав 2507 | Шестигранные трубы Super Duplex 2507 |

| Капиллярные трубки из сплава 2507 | Трубы ASTM A790 SAF 2507 по индивидуальному заказу |

| Трубы Super Duplex 2507 малого диаметра | Прямоугольные трубы Super Duplex 2507 |

| Трубы высокого давления 2507 Super Duplex | Капиллярный сплав 2507 Тонкие трубы |

| ВЕРКСТОФФ Н.Р. 2.4856 Плакированные трубы | Трубы шестигранные втулки Super Duplex 2507 |

| Тонкостенные трубы Super Duplex 2507 | 2507 Квадратные трубы из сплава |

| Прямоугольная трубка Super Duplex 2507 | Эллиптическая и овальная трубка из сплава 2507 |

| Супердуплекс 2507 SCH 80 Трубка | Трубка из сплава SAF 2507 SCH 40 |

| Сильфонные трубки Super Duplex 2507 | Super Duplex 2507 Высокопрочные капиллярные трубки |

| Супердуплексные передающие трубки 2507 | Прецизионные трубы ASME SA790 SAF 2507 |

| Электрополированная труба ASME SA790 Super Duplex 2507 | Трубка для инструментов Super Duplex 2507 |

| Электрополированная трубка Super Duplex 2507 | Бесшовная полая труба Super Duplex 2507 |

| ASTM A790 SAF 2507 Нефтегазовые трубы | Конденсаторная трубка Super Duplex 2507 |

| Супердуплекс 2507 SCH 80 Трубка | Супердуплекс 2507 SCH 40 трубка |

| Трубы для авиационных двигателей Super Duplex 2507 | Холоднотянутые бесшовные трубы Super Duplex 2507 |

| Трубы печи Super Duplex 2507 | Газопроводная трубка Super Duplex 2507 |

| Холоднотянутые бесшовные трубы (CDS) из стали марки Super Duplex 2507 | Супердуплекс 2507 Горячедеформированные бесшовные трубы (HFS) |

| Трубки высокого давления Super Duplex 2507 | Прецизионные трубки из сплава SAF 2507 |

| ASME SA790 SAF 2507 Капиллярная трубка | Трубки Бурдона Super Duplex 2507 |

| Ребристые трубы из сплава 2507 | Супердуплекс 2507, вытянутый на оправке (DOM) |

| Трубы печи Super Duplex 2507 | Трубы для авиакосмических двигателей Super Duplex 2507 |

| Трубка прямая бесшовная Super Duplex 2507 | Бесшовные гибкие трубы Super Duplex 2507 |

Выбирайте Daxun и сделайте своих клиентов довольными.

Быстрый ответ Труба из нержавеющей стали 2507

- Очень сильная устойчивость к равномерной коррозии

- Хорошая устойчивость к неорганическим кислотам/хлоридам

- Для использования с разбавленной соляной кислотой

- Улучшенная обрабатываемость и свариваемость

- Устойчив к коррозионному растрескиванию под напряжением в хлоридсодержащих материалах

- Отличная стойкость к точечной и щелевой коррозии

- Высокая устойчивость к общей коррозии

- чрезвычайно высокая механическая прочность

- Хорошая свариваемость

- Высокая ударная вязкость

Политика качества труб из нержавеющей стали 2507

Компания Daxun Alloy стремится поставлять клиентам продукцию без дефектов путем:

Производство высококачественных и ценных труб из нержавеющей стали 2507, быстрое реагирование и своевременная доставка, уделяя большое внимание охране здоровья, безопасности и защите окружающей среды, а также соблюдению законов. Используйте наш опыт и культуру постоянного совершенствования, чтобы соответствовать или превосходить ожидания и требования клиентов к трубам из нержавеющей стали 2507.

Качество, доставка, проверка

- Труба из нержавеющей стали 2507:

- Daxun также проводит несколько испытаний на обеспечение качества. Эти испытания включают испытание на сплющивание, испытание на питтинг и сопротивление, механическое испытание, испытание на твердость, положительную идентификацию материала, испытание на расширение и т. д. Все эти испытания гарантируют, что материал подходит для требуемого применения.

- В процессе производства мы измеряем диаметр, толщину и поверхность изделия. Наш стандартный срок поставки составляет 7-15 дней, за исключением некоторых изделий специального размера, срок поставки увеличивается до 20 дней.

Срок поставки строго соответствует договору. - Поддержка сторонних агентств-клиентов при посещении завода для проведения инспекции

- Предоставляем бесплатные образцы клиентам для тестирования

- Поддержка инспекции завода на месте или видеоинспекции

Упаковка для труб из нержавеющей стали 2507

- Тканый мешок для перевозки грузов (шестиугольный)

- Специальные ящики для U-образных труб (сталь/дерево) разделенные

- Каждый тюк упакован в пленку для защиты от ветра и дождя.

- Бесшовные трубы SS 2507 защищены пластиковыми кожухами.

- Для фиксации тюка используются пластиковые полосы.

- Специальная экспортная упаковка из деревянных ящиков, не прошедших фумигацию.

- Ламинированная упаковочная накладная, прикрепленная к тюку или ящику.

- Индивидуальная упаковка в соответствии с потребностями заказчика.

Информация для заказа труб из нержавеющей стали 2507

Труба из нержавеющей стали Duplex 2507/S32750 Заказ на покупку должен включать количество, марку PSL, тип или класс, ссылку API5L, наружный диаметр, толщину стенки, длину и любые применимые насадки или дополнительные требования, связанные с химическим составом, механическими свойствами, термической обработкой, дополнительными испытаниями, производственным процессом, покрытием поверхности или конечной отделкой. Труба отожжена на растворе.

Техническая поддержка

Если вам нужна дополнительная техническая помощь, наш местный металлург и знающий персонал будут рады помочь. Кроме того, Daxun может похвастаться сертифицированной испытательной лабораторией — первой в отрасли многометаллического и пластикового инвентаря. Это, по нашему мнению, демонстрирует нашу непоколебимую преданность качеству и нашу философию как поставщика полного спектра услуг.

Характеристики труб и трубок из сплавов нержавеющей стали Super Duplex 2507

Сделайте так, как поступили многие другие компании, — положитесь на сплав Daxun.

- Галерея

- 2507 СТАЛЬНАЯ ТРУБА ИНФОРМАЦИОННАЯ ТРУБКА

- НОМИНАЛЬНОЕ ДАВЛЕНИЕ

- РАЗМЕР

- Отделка поверхности

| НПС | Внешний диаметр | Толщина стенки | Масса | Масса | |||

| в | мм | в | мм | Расписано | кг/мтр | Фунт/фут | |

| 1/2″ | 0,84 | двадцать один | 0,109 | 2.769 | 40 СТД | 1.268 | 0,851 |

| 0,147 | 3.734 | 80 СТД | 1.621 | 1.088 | |||

| 3/4″ | 1.05 | 27 | 0,113 | 2.87 | 40 СТД | 1.684 | 1.131 |

| 0,154 | 3.912 | 80 СТД | 2.195 | 1.474 | |||

| 1″ | 1.315 | 33 | 0,133 | 3.378 | 40 СТД | 2.501 | 1.679 |

| 0,179 | 4.547 | 80 СТД | 3.325 | 2.172 | |||

| 1 1/4″ | 1.66 | 42 | 0,14 | 3.556 | 40 СТД | 3.385 | 2.273 |

| 0,191 | 4.851 | 80 СТД | 4.464 | 2.997 | |||

| 1 1/2″ | 1.9 | 48 | 0,145 | 3.683 | 40 СТД | 4.048 | 2.718 |

| 0.2 | 5.08 | 80 СТД | 5.409 | 3.361 | |||

| 2″ | 2.375 | 60 | 0,154 | 3.912 | 40 СТД | 5.441 | 3.653 |

| 0,218 | 5.537 | 80 СТД | 7.48 | 5.022 | |||

| 2 1/2″ | 2.875 | 73 | 0,203 | 5.516 | 40 СТД | 8.629 | 5.793 |

| 0,276 | 7.01 | 80 СТД | 11.411 | 7.661 | |||

| 3″ | 3.5 | 89 | 0,216 | 5.486 | 40 СТД | 11.284 | 7.576 |

| 0.3 | 7.62 | 80 СТД | 15.272 | 10.253 | |||

| 4″ | 4.5 | 114 | 0.237 | 6.02 | 16.073 | 10.79 | |

| 0,337 | 8.56 | 22.318 | 14.983 | ||||

| 6″ | 6.625 | 168 | 0,188 | 4.775 | 19.252 | 12.924 | |

| 0,203 | 5.516 | 20.739 | 13.923 | ||||

| 0,219 | 5.563 | 22.318 | 14.983 | ||||

| 0,25 | 6.35 | 25.354 | 17.021 | ||||

| 0,28 | 7.112 | 40 СТД | 58.263 | 18.974 | |||

| 0,312 | 7.925 | 31.334 | 21.036 | ||||

| 0,375 | 9.525 | 37.285 | 25.031 | ||||

| 0,432 | 10.973 | 80 XHY | 42.561 | 28.573 | |||

| 0,5 | 12.7 | 48.719 | 32.708 | ||||

| 8″ | 8.625 | 219 | 0,188 | 4.775 | 25.233 | 16.94 | |

| 0,203 | 5.156 | 27.198 | 18.259 | ||||

| 0,219 | 5.563 | 29.286 | 19.661 | ||||

| 0,25 | 6.35 | 20 | 33.308 | 22.361 | |||

| 0,277 | 7.036 | 30 | 36.786 | 24.696 | |||

| 0,322 | 8.179 | 40 | 42.352 | 28.554 | |||

| 0,375 | 9.525 | 49.216 | 33.041 | ||||

| 0,406 | 10.312 | 60 | 53.085 | 35.638 | |||

| 0,5 | 12.7 | 80 XHY | 64.627 | 43.388 | |||

| 10″ | 10.75 | 273 | 0,188 | 4.775 | 31.588 | 21.207 | |

| 0,219 | 5.563 | 36.689 | 24.631 | ||||

| 0,25 | 6.35 | 20 | 41.759 | 28.035 | |||

| 0,307 | 7.798 | 30 | 51.002 | 34.24 | |||

| 0,344 | 8.738 | 56.946 | 38.231 | ||||

| 0,365 | 9.271 | 40 СТД | 63.301 | 40.483 | |||

| 0,438 | 11.125 | 71.852 | 48.238 | ||||

| 0,5 | 12.7 | 60 ХХУ | 81,53 | 54.735 | |||

| 0,594 | 15.088 | 80 | 95.969 | 64.429 | |||

| 12″ | 12.75 | 324 | 0,188 | 4.775 | 37.57 | 25.222 | |

| 0,219 | 5.563 | 43.657 | 29.309 | ||||

| 0,25 | 6.35 | 49.713 | 33.375 | ||||

| 0,281 | 7.137 | 55.739 | 37.42 | ||||

| 0,312 | 7.925 | 61.735 | 41.445 | ||||

| 0,375 | 9.525 | 73.824 | 49.562 | ||||

| 0,406 | 10.312 | 79.727 | 53.525 | ||||

| 0,5 | 12.7 | 97.438 | 65.415 | ||||

| 0,562 | 14.275 | 108.966 | 73.154 | ||||

| 14″ | 14 | 356 | 0,188 | 4.775 | 41.308 | 27.732 | |

| 0,219 | 5.563 | 48.012 | 32.233 | ||||

| 0,25 | 6.35 | 20 | 54.685 | 36.713 | |||

| 0,281 | 7.137 | 61.327 | 41.172 | ||||

| 0,312 | 7.925 | 67.939 | 45.611 | ||||

| 0,375 | 9.525 | ЗППП | 81.281 | 54.568 | |||

| 0,438 | 11.125 | 40 | 94.498 | 63.441 | |||

| 0,5 | 12.7 | XHY | 107.381 | 72.09 | |||

| 0,625 | 15.875 | 132.983 | 89.278 | ||||

| 16” | 16 | 406 | 0,188 | 4.775 | 47.29 | 21.748 | |

| 0,219 | 5.563 | 54.98 | 36.91 | ||||

| 0,25 | 6.35 | 10 | 62.639 | 42.053 | |||

| 0,281 | 7.137 | 70.268 | 47.174 | ||||

| 0,312 | 7.925 | 20 | 77.866 | 52.275 | |||

| 0,344 | 8.738 | 85.677 | 57.519 | ||||

| 0,375 | 9.525 | 30 | 93.213 | 62.578 | |||

| ЗППП | |||||||

| 0,438 | 11.125 | 108.433 | 72.797 | ||||

| 0,5 | 12.7 | 40 | 123.289 | 82.77 | |||

| XHY | |||||||

| 18″ | 18 | 457 | 0,219 | 5.563 | 61.948 | 41.588 | |

| 0,25 | 6.35 | 70.593 | 47.393 | ||||

| 0,281 | 7.137 | 79.208 | 53.176 | ||||

| 0,312 | 7.925 | 20 | 87.792 | 58.939 | |||

| 0,375 | 9.525 | ЗППП | 105.144 | 70.588 | |||

| 0,438 | 11.125 | 30 | 122.369 | 82.152 | |||

| 0,5 | 12.7 | XHY | 139.198 | 93.45 | |||

| 0,562 | 14.275 | 40 | 155.904 | 104.666 | |||

| 0,625 | 15.875 | 172.754 | 115.978 | ||||

| 20″ | 20 | 508 | 0,25 | 6.35 | 78.547 | 52.733 | |

| 0,282 | 7.163 | 88.458 | 59.386 | ||||

| 0,312 | 7.925 | 97.719 | 65.604 | ||||

| 0,375 | 9.525 | 20 СТД | 117.075 | 78.598 | |||

| 0,438 | 11.125 | 136.305 | 91.508 | ||||

| 0,5 | 12.7 | 30 ХХУ | 155.106 | 104.13 | |||

| 0,594 | 15.088 | 40 | 183.378 | 123.11 | |||

| 0,625 | 15.875 | 192.64 | 129.328 | ||||

| 0,688 | 17.475 | 211.368 | 141.901 | ||||

| двадцать четыре” | двадцать четыре | 610 | 0,25 | 6.35 | 94.456 | 63.413 | |

| 0,281 | 7.137 | 106.029 | 71.183 | ||||

| 0,312 | 7.925 | 117.573 | 18.932 | ||||

| 0,375 | 9.525 | 20 СТД | 140.938 | 64.618 | |||

| 0,438 | 11.125 | 164.176 | 110.219 | ||||

| 0,5 | 12.7 | XHY | 186.923 | 125.49 | |||

| 0,625 | 15.875 | 232.41 | 156.028 | ||||

| 0,688 | 17.475 | 40 | 255.148 | 171.293 | |||

| 0,75 | 19.05 | 277.401 | 186.233 | ||||

| 30″ | 30 | 762 | 0,25 | 6.35 | 118.318 | 79.433 | |

| 0,281 | 7.137 | 132.851 | 89.189 | ||||

| 0,312 | 7.925 | 10 | 147.353 | 98.925 | |||

| 0,375 | 9.525 | ЗППП | 176.731 | 118.648 | |||

| 0,438 | 11.125 | 205.983 | 138.286 | ||||

| 0,5 | 12.7 | 20 XHY | 234.647 | 157,53 | |||

| 0,625 | 15.875 | 30 | 292.066 | 196.078 | |||

| 0,688 | 17.475 | 320.817 | 215.38 | ||||

| 0,75 | 19.05 | 348.988 | 234.293 | ||||

| 36″ | 36 | 914 | 0,25 | 6.35 | 142.18 | 95.453 | |

| 0,281 | 7.137 | 159.672 | 107.196 | ||||

| 0,312 | 7.925 | 10 | 177.133 | 118.918 | |||

| 0,375 | 9.525 | ЗППП | 215.525 | 142.678 | |||

| 0,438 | 11.125 | 247.79 | 166.353 | ||||

| 0,5 | 12.7 | 20 XHY | 282.372 | 198.57 | |||

| 0,625 | 15.875 | 351.723 | 236.128 | ||||

| 0,688 | 17.475 | 386.487 | 259.467 | ||||

| 0,75 | 19.05 | 420.576 | 282.353 | ||||

| 42″ | 42 | 1067 | 0,312 | 7.925 | 206.914 | 138.911 | |

| 0,375 | 9.525 | ЗППП | 248.319 | 166.708 | |||

| 0,5 | 12.7 | XHY | 33.097 | 221.61 | |||

| 0,75 | 19.05 | 492.163 | 330.413 | ||||

| 48″ | 48 | 1219 | 0,375 | 9.525 | ЗППП | 284.112 | 190.738 |

| 0,438 | 11.125 | 331.404 | 222.487 | ||||

| 0,5 | 12.7 | XHY | 377.822 | 253,65 | |||

| 0,75 | 19.05 | 563,75 | 378.473 | ||||

| 0,875 | 22.225 | 655.969 | 440.383 | ||||

| НОМИНАЛЬНОЕ ДАВЛЕНИЕ (PSIG) | ||||||||||||

| РАЗМЕРЫ | РАСПИСАНИЕ (SCH) | СНАРУЖИ | СТЕНА | ТЕМПЕРАТУРА (ОФ) | ||||||||

| (ДЮЙМЫ) | ДИА. | ТОЛСТЫЙ. | 100 | 200 | 300 | 400 | 500 | 600 | 650 | 700 | 750 | |

| (В) | (В) | ДОПУСТИМОЕ НАПРЯЖЕНИЕ (PSI) | ||||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | 13500 | 13200 | 12900 | 12600 | ||||

| 1″ | 40 | 1.315 | 0,133 | 2205 | 2205 | 2205 | 2047 | 1902 | 1783 | 1743 | 1703 | 1664 |

| 80 | 1.315 | 0,179 | 3061 | 3061 | 3061 | 2841 | 2640 | 2475 | 2420 | 2365 | 2310 | |

| 160 | 1.315 | 0,25 | 4493 | 4493 | 4493 | 4170 | 3874 | 3632 | 3552 | 3471 | 3390 | |

| 1 1/2″ | 40 | 1.9 | 0,145 | 1629 | 1629 | 1629 | 1512 | 1404 | 1317 | 1287 | 1258 | 1229 |

| 80 | 1.9 | 0.2 | 2303 | 2303 | 2303 | 2138 | 1986 | 1862 | 1821 | 1779 | 1738 | |

| 160 | 1.9 | 0,281 | 3362 | 3362 | 3362 | 3120 | 2899 | 2717 | 2657 | 2597 | 2536 | |

| 2″ | 40 | 2.375 | 0,154 | 1371 | 1371 | 1371 | 1272 | 1182 | 1108 | 1083 | 1059 | 1034 |

| 80 | 2.375 | 0,218 | 1985 | 1985 | 1985 | 1843 | 1712 | 1605 | 1569 | 1534 | 1498 | |

| 160 | 2.375 | 0,344 | 3283 | 3283 | 3283 | 3047 | 2831 | 2654 | 2595 | 2536 | 2477 | |

| 3″ | 40 | 3.5 | 0,216 | 1301 | 1301 | 1301 | 1208 | 1122 | 1052 | 1028 | 1005 | 982 |

| 80 | 3.5 | 0.3 | 1844 | 1844 | 1844 | 1712 | 1590 | 1491 | 1458 | 1425 | 1391 | |

| 160 | 3.5 | 0,438 | 2787 | 2787 | 2787 | 2587 | 2403 | 2253 | 2203 | 2153 | 2103 | |

| 4″ | 40 | 4.5 | 0.237 | 1102 | 1102 | 1102 | 1023 | 950 | 891 | 871 | 851 | 831 |

| 80 | 4.5 | 0,337 | 1596 | 1596 | 1596 | 1482 | 1377 | 1291 | 1262 | 1233 | 1204 | |

| 160 | 4.5 | 0,531 | 2611 | 2611 | 2611 | 2424 | 2552 | 2111 | 2064 | 2017 | 1970 | |

| 5″ | 40 | 5.563 | 0,258 | 965 | 965 | 965 | 896 | 832 | 780 | 763 | 746 | 728 |

| 80 | 5.563 | 0,375 | 1428 | 1428 | 1428 | 1325 | 1231 | 1154 | 1129 | 1103 | 1077 | |

| 160 | 5.563 | 0,625 | 2474 | 2474 | 2474 | 2296 | 2133 | 2000 | 1955 | 1911 | 1866 | |

| 6″ | 40 | 6.625 | 0,28 | 877 | 877 | 877 | 814 | 756 | 709 | 693 | 677 | 661 |

| 80 | 6.625 | 0,432 | 1379 | 1379 | 1379 | 1280 | 1189 | 1115 | 1090 | 1065 | 1040 | |

| 160 | 6.625 | 0,719 | 2382 | 2382 | 2382 | 2211 | 2054 | 1925 | 1883 | 1840 | 1797 | |

| 8″ | 40 | 8.625 | 0,322 | 771 | 771 | 771 | 716 | 665 | 623 | 610 | 596 | 582 |

| 80 | 8.625 | 0,5 | 1218 | 1218 | 1218 | 1131 | 1050 | 985 | 963 | 941 | 919 | |

| 160 | 8.625 | 0,906 | 2298 | 2298 | 2298 | 2133 | 1982 | 1858 | 1817 | 1775 | 1734 | |

| 10″ | 40 | 10.75 | 0,365 | 699 | 699 | 699 | 649 | 603 | 565 | 553 | 540 | 528 |

| 80 | 10.75 | 0,594 | 1159 | 1159 | 1159 | 1075 | 999 | 937 | 916 | 895 | 874 | |

| 160 | 10.75 | 1.125 | 2289 | 2289 | 2289 | 2124 | 1974 | 1850 | 1809 | 1768 | 1727 | |

| Типы | Внешний диаметр | Размеры | Длина |

| Примечание: Размеры (в наличии) | .0035” ~ 20” | 1/8″, 1/4″, 3/8″, 1/2″, 5/8″, 3/4″, 1″, 1.25″, 1.5″, 2″, 2.5″, 3″, 4″, 5″, 6″ и т. д. | Отрезать по длине |

| Бесшовная труба из нержавеющей стали 2507/S32750 (нестандартные размеры) | Внешний диаметр 6,35 мм до 508 мм | Согласно требованиям | Отрезать по длине |

| Сварная труба из нержавеющей стали 2507/S32750 (труба ERW) (в наличии + индивидуальные размеры) | Внешний диаметр 6,35 мм до внешнего диаметра 1219 мм | Согласно требованиям | Отрезать по длине |

| Отделка поверхности | Внутренняя поверхность (ID) | Внешняя поверхность (OD) | |||

| Средняя шероховатость (RA) | Средняя шероховатость (RA) | ||||

| мк дюйм | мкм | мк дюйм | мкм | ||

| АП | Отожженный и маринованный | Не определено | Не определено | 40 или не определено | 1.0 или не определено |

| БА | Отожженный по высоте | 40,32,25,20 | 1.0,0.8,0.6,0.5 | 32 | 0,8 |

| МП | Механическая полировка | 40,32,25,20 | 1.0,0.8,0.6,0.5 | 32 | 0,8 |

| ЭП | Электро-полироль | 15,10,7,5 | 0,38,0,25,0,20;0,13 | 32 | 0,8 |

Поверхность и форма пластины из нержавеющей стали Duplex 2507/S32750 (6)

Информация доступна для ознакомления и скачивания

Daxun — надежный производитель труб из нержавеющей стали.

Как профессиональный производитель, Daxun гарантирует, что вся производимая нами продукция отличается высоким качеством. Поэтому мы гарантируем, что все трубы из нержавеющей стали сертифицированы по стандартам ISO9001, SGS, CE, OQC

Последние горячие проекты и продукты

Сопутствующие товары (9)

Ведущие поставщики труб из нержавеющей стали в Китае

ДУПЛЕКС 2507 НЕРЖАВЕЮЩАЯ СТАЛЬ

- В настоящее время на складе Daxun Alloy Stainless Steel имеется труба из нержавеющей стали Duplex 2507, которая представляет собой супердуплексную нержавеющую сталь, содержащую 25% хрома, 4% молибдена и 7% никеля. Сплав подходит для применений, требующих высокой прочности и коррозионной стойкости, таких как химическая обработка, нефтехимическое и морское оборудование. Сталь обладает высокой стойкостью к хлоридному коррозионному растрескиванию под напряжением, хорошей теплопроводностью и низким коэффициентом теплового расширения. Высокое содержание хрома, молибдена и никеля обеспечивает отличную стойкость к точечной, щелевой и общей коррозии.

ОБЩИЕ СВОЙСТВА

- Duplex 2507 (UNS S32750) — это труба из супердуплексной нержавеющей стали, содержащая 25% хрома, 4% молибдена и 7% никеля. Она предназначена для сложных применений, требующих высокой прочности и коррозионной стойкости, таких как химическая переработка, нефтехимическое и морское оборудование. Сталь обладает высокой стойкостью к хлоридному коррозионному растрескиванию под напряжением, высокой теплопроводностью и низким коэффициентом теплового расширения. Высокое содержание хрома, молибдена и никеля обеспечивает отличную стойкость к точечной, щелевой и общей коррозии.

Приложения

- Оборудование для нефтегазовой промышленности

- Морские платформы, теплообменники, системы технологического и технического водоснабжения, системы пожаротушения, системы закачки и балластной воды

- Химическая промышленность, теплообменники, сосуды и трубопроводы

- Опреснительные установки, установки обратного осмоса высокого давления и трубопроводы морской воды

- Механические и структурные компоненты, высокопрочные, коррозионно-стойкие детали

- Системы FGD для энергетической промышленности, коммунальные и промышленные скрубберные системы, абсорбционные башни, воздуховоды и трубопроводы

Стандарты

- АСТМ/АСМЕ…………. A240 – UNS S32750

ЕВРОНОРМ………… 1.4410 – X2 Cr Ni MoN 25.7.4

AFNOR……………….. Z3 CN 25.06 Az

КОРРОЗИОННАЯ УСТОЙЧИВОСТЬ

Общая коррозия

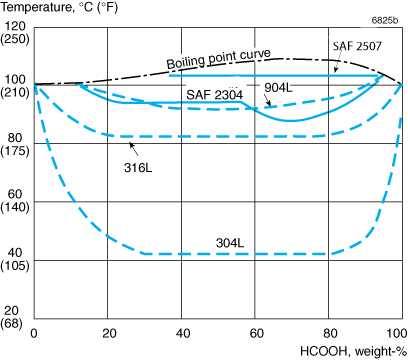

- SAF 2507™ обладает высокой устойчивостью к коррозии, вызываемой органическими кислотами, например, менее 0,05 мм/год в 10% муравьиной и 50% уксусной кислоте, тогда как у ASTM 316L скорость коррозии превышает 0,2 мм/год. Чистая муравьиная кислота, см. рисунок 4. Также в загрязненной кислоте SAF 2507™ остается устойчивым.

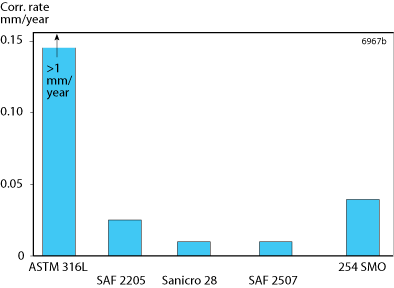

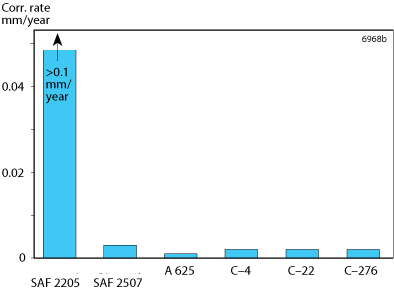

- На рисунках 5 и 6 показаны результаты испытаний SAF™ 2507 и различных нержавеющих сталей и никелевых сплавов в уксусной кислоте, загрязненной хлоридами, которые на практике часто присутствуют в технологических процессах.

Рисунок 4. Диаграмма изокоррозии в муравьиной кислоте. Кривые представляют скорость коррозии 0,1 мм/год (4 мпг) в застойном тестовом растворе.

Рисунок 5. Скорость коррозии различных сплавов в 80% уксусной кислоте с 2000 ppm хлорид-ионов при 90°C.

Рисунок 6. Скорость коррозии различных сплавов в концентрированной уксусной кислоте с 200 ppm хлорид-ионов.

Практический опыт использования SAF™ 2507 в органических кислотах, например, на заводах по производству терефталевой кислоты, показал, что этот сплав обладает высокой устойчивостью к этому типу среды. Таким образом, сплав является конкурентоспособной альтернативой высоколегированным аустенитам и никелевым сплавам в приложениях, где стандартные аустенитные нержавеющие стали подвергаются коррозии с высокой скоростью.

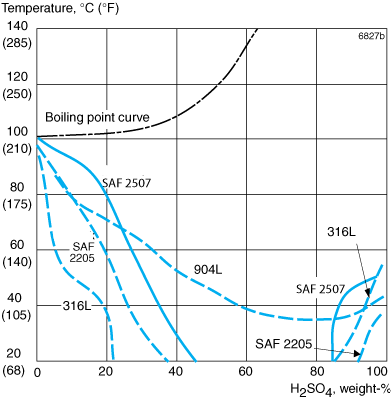

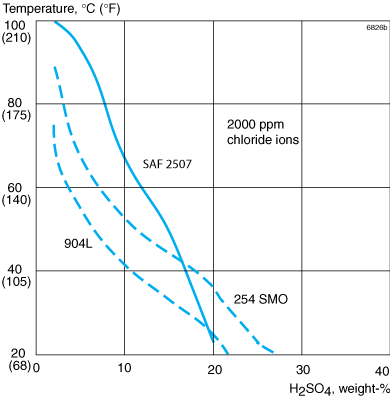

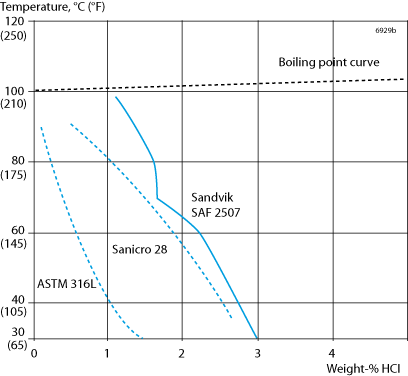

Стойкость к неорганическим кислотам сопоставима или даже превосходит стойкость высоколегированных аустенитных нержавеющих сталей в определенных диапазонах концентраций. На рисунках 7–9 показаны изокоррозионные диаграммы для серной кислоты, серной кислоты, загрязненной 2000 ppm хлорид-ионов, и соляной кислоты соответственно.

Рисунок 7. Диаграмма изокоррозии в естественно аэрированной серной кислоте. Кривые представляют скорость коррозии 0,1 мм/год (4 мпг) в застойном тестовом растворе.

Рисунок 8. Диаграмма изокоррозии, 0,1 мм/год (4 мпг) в естественно аэрированной серной кислоте, содержащей 2000 ppm хлорид-ионов.

Рисунок 9. Диаграмма изокоррозии в соляной кислоте. Кривые представляют скорость коррозии 0,1 мм/год (4 мпг) в застойном тестовом растворе.

Питтинговая и щелевая коррозия

Стойкость нержавеющей стали к точечной и щелевой коррозии определяется в первую очередь содержанием хрома, молибдена и азота. Производственные и производственные методы, например, сварка, также имеют важное значение для фактической производительности в эксплуатации.

Параметром для сравнения стойкости к точечной коррозии в хлоридной среде является число PRE (эквивалент стойкости к точечной коррозии).

PRE определяется как, в весовых процентах

PRE = %Cr + 3,3 x %Mo + 16 x %N

Для дуплексных нержавеющих сталей стойкость к точечной коррозии зависит от значения PRE как в ферритной фазе, так и в аустенитной фазе, так что фаза с самым низким значением PRE будет ограничивать фактическую стойкость к точечной коррозии. В SAF™ 2507 значение PRE одинаково в обеих фазах, что достигается за счет тщательного баланса элементов.

Минимальное значение PRE для бесшовных труб SAF™ 2507 составляет 42,5. Это значительно выше, чем, например, значения PRE для других дуплексных нержавеющих сталей типа 25Cr, которые не являются супердуплексными. Например, UNS S31260 25Cr3Mo0.2N имеет минимальное значение PRE 33.

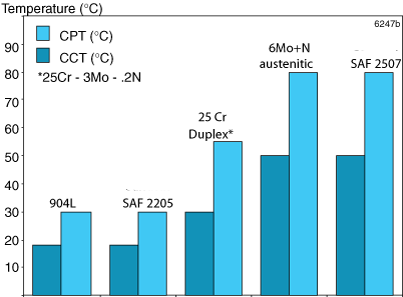

Одним из самых жестких испытаний на точечную и щелевую коррозию, применяемых к нержавеющей стали, является ASTM G48, т. е. воздействие 6% FeCl 3 с трещинами и без них (методы A и B соответственно). В модифицированной версии испытания ASTM G48 A образец подвергается воздействию в течение 24 часов. При обнаружении точечных дефектов вместе со значительной потерей веса (>5 мг) испытание прерывается. В противном случае температуру повышают на 5 °C (9 °F) и испытание продолжают с тем же образцом. На рисунке 11 показаны критические температуры точечного и щелевого дефектов (CPT и CCT) по результатам испытания.

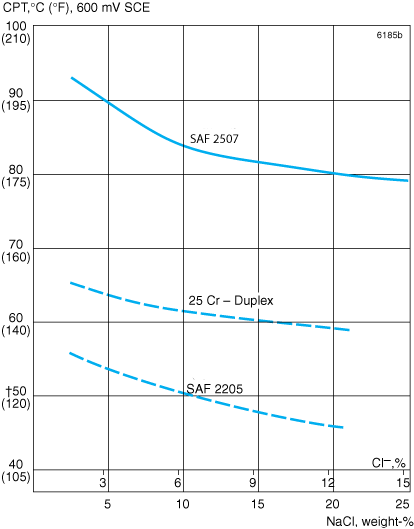

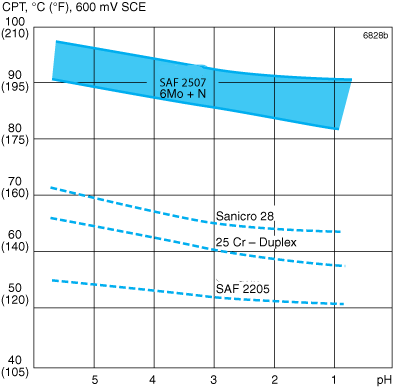

Потенциостатические испытания в растворах с различным содержанием хлорида представлены на рисунке 11. Рисунок 12 показывает влияние повышенной кислотности. В обоих случаях приложенный потенциал составляет 600 мВ против SCE, что является очень высоким значением по сравнению с тем, которое обычно ассоциируется с естественной нехлорированной морской водой, что приводит к более низким критическим температурам по сравнению с большинством практических условий эксплуатации.

Рисунок 10. Критические температуры образования питтингов и трещин в 6% FeCl 3 , 24 ч (аналогично ASTM G48).

Полоса рассеяния для SAF™ 2507 и 6Mo+N иллюстрирует тот факт, что оба сплава имеют одинаковую стойкость к точечной коррозии, а значения CPT находятся в диапазоне, показанном на рисунке.

Испытания проводились в естественной морской воде для определения критической температуры щелевой коррозии образцов с приложенным потенциалом 150 мВ против SCE. Температура повышалась на 4°C (7 o F) каждые 24 часа до тех пор, пока не возникала щелевая коррозия. Результаты показаны в таблице ниже.

| Сплав | ЦКТ (°С) |

|---|---|

| САФ 2507 | 64 |

| 6Мо+N | 61 |

В этих испытаниях также определялись скорости распространения инициированных щелевых коррозионных атак при 15-50°C (59-122°F) и приложенном потенциале 150 мВ против SCE. Было обнаружено, что они примерно в десять раз ниже для SAF™ 2507, чем для сплава 6Mo+N.

Рисунок 11. Критические температуры питтинговой коррозии (КТК) при различных концентрациях хлорида натрия от 3 до 25% (потенциостатическое определение при +600 мВ SCE с поверхностью, отшлифованной наждачной бумагой зернистостью 600).

Рисунок 12. Критические температуры питтинговой коррозии (КТК) в 3% NaCl при различных значениях pH (потенциостатическое определение при +600 мВ SCE с поверхностью, отшлифованной наждачной бумагой зернистостью 600).

Коррозионная стойкость SAF™ 2507 в окисляющих хлоридных растворах иллюстрируется критическими температурами точечной коррозии (CPT), определенными в растворе «Зеленая смерть» (1% FeCl3 + 1% CuCl2 + 11 % H2SO4 + 1,2% HCl) и в растворе «Желтая смерть» (0,1% Fe2 ( SO4 ) 3 + 4 % NaCl + 0,01 M HCl). В таблице ниже приведены значения CPT для различных сплавов в этих растворах. Очевидно, что значения для SAF™ 2507 находятся на том же уровне, что и для никелевого сплава UNS N06625. Испытания демонстрируют хорошую корреляцию с рейтингом сплавов для использования в качестве труб подогревателей в системах десульфурации дымовых газов.

Критическая температура питтинга (КТП), определенная в различных испытательных растворах.

| Сплав | Критическая температура питтинга (КТП), °C «Зеленая смерть» |

«Желтая смерть» |

|---|---|---|

| САФ™ 2507 | 72,5 | >90 |

| 6Мо+N | 70 | >90 |

| УНС N06625 | 67,5 | >90 |

| АСTM 316 | <25 | 20 |

Коррозионное растрескивание под напряжением

SAF™ 2507 обладает превосходной стойкостью к коррозионному растрескиванию под напряжением, вызванному хлоридами.

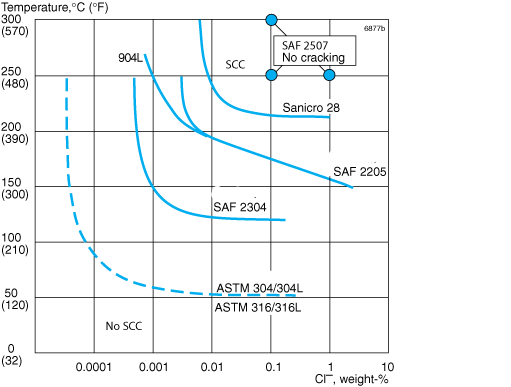

Стойкость SAF™ 2507 к КРН в хлоридных растворах при высоких температурах показана на рисунке 13. Признаки КРН отсутствуют до 1000 ppm Cl – /300 °C и 10000 ppm Cl – /250 °C.

Образцы U-образного изгиба SAF™ 2507, выдержанные в течение 1000 часов в горячем рассоле (108 °C, 226 °F, 25% NaCl), не показали трещин.

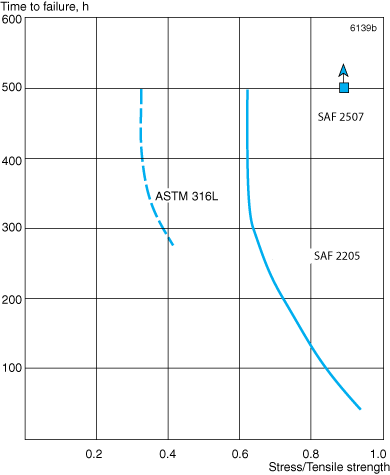

Пороговое напряжение для SAF 2507 ® в 40% CaCl 2 при 100 °C (210 °F) и pH = 6,5 превышает 90% предела прочности на растяжение как для основного металла, так и для сварных соединений (сварка TIG с Alleima® 25.10.4.L или сварка MMA с Alleima® 25.10.4.LR).

На рисунке 14 показан результат испытания в 40% CaCl 2 при 100 °C (210 °F), подкисленном до pH = 1,5. Подкисление стандартного испытательного раствора до pH = 1,5 снижает пороговое напряжение для SAF™ 2205, но не для SAF™ 2507. Это относится как к основному металлу, так и к сварным соединениям.

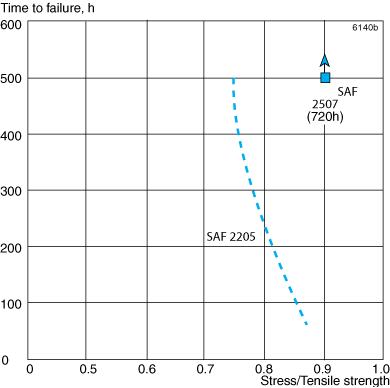

Пороговое напряжение как для основного металла, так и для сварных соединений SAF™ 2507 в кипящем 45% MgCl2 , 155°C (311°F) (ASTM G36) составляет приблизительно 50% от предела текучести.

Рисунок 13. Стойкость к SCC в нейтральных хлоридных растворах, содержащих кислород (около 8 ppm). Время испытания 1000 часов. Приложенное напряжение равно пределу текучести при температуре испытания.

Рисунок 14. Результаты испытаний SCC с постоянной нагрузкой в 40% CaCl 2 , pH = 1,5, при 100 °C (210 °F) с аэрированным испытательным раствором.

Рисунок 15. Испытания SCC при постоянной нагрузке в растворе NACE при комнатной температуре (NACE TM 0177).

На рисунке 15 показаны результаты испытаний SCC при комнатной температуре в тестовом растворе NACE TM0177 A (5% хлорида натрия и 0,5% уксусной кислоты, насыщенной сероводородом). На SAF™ 2507 трещин не наблюдалось, независимо от приложенного напряжения.

В водных растворах, содержащих сероводород и хлориды, коррозионное растрескивание под напряжением может также происходить на нержавеющих сталях при температурах ниже 60 °C (140 °F). Коррозионная активность таких растворов зависит от кислотности и содержания хлоридов. В отличие от случая с обычным коррозионным растрескиванием под напряжением, вызванным хлоридами, ферритные нержавеющие стали более чувствительны к этому типу коррозионного растрескивания под напряжением, чем аустенитные стали.

В соответствии со стандартом ISO 15156/NACE MR 0175 отожженная на твердый раствор и быстро охлажденная деформируемая сталь SAF™ 2507 пригодна для использования при температурах до 450 °F (232 °C) в кислых средах при добыче нефти и газа, если парциальное давление сероводорода не превышает 3 фунтов на кв. дюйм (0,20 бар).

SAF™ 2507 с максимальной твердостью 32 HRC, подвергнутый отжигу на твердый раствор и быстрому охлаждению в соответствии с NACE MR0103, пригоден для использования при переработке высокосернистой нефти.

Растрескивание под действием водорода (HISC)

Растрескивание под действием водорода (HISC) — это явление охрупчивания, которое может возникнуть в подводных стальных конструкциях с катодной защитой при наличии высоких растягивающих напряжений. При соединении с катодной защитой углеродистых сталей супердуплексные нержавеющие стали также будут катодно защищены, хотя это не обязательно. При преобладающих низких электрохимических потенциалах атомарный водород будет образовываться на стальных поверхностях за счет восстановления морской воды. Охрупчивание из-за HISC может возникнуть, когда водород диффундирует в металл.

Водород диффундирует гораздо быстрее в ферритной фазе, чем в аустенитной. Поэтому ферритные стали и стали, содержащие феррит, например, супердуплексные нержавеющие стали, более восприимчивы к HISC, чем аустенитные нержавеющие стали. Высокое механическое напряжение увеличивает риск HISC за счет увеличения скорости диффузии водорода, возникновения и распространения трещин в материале.

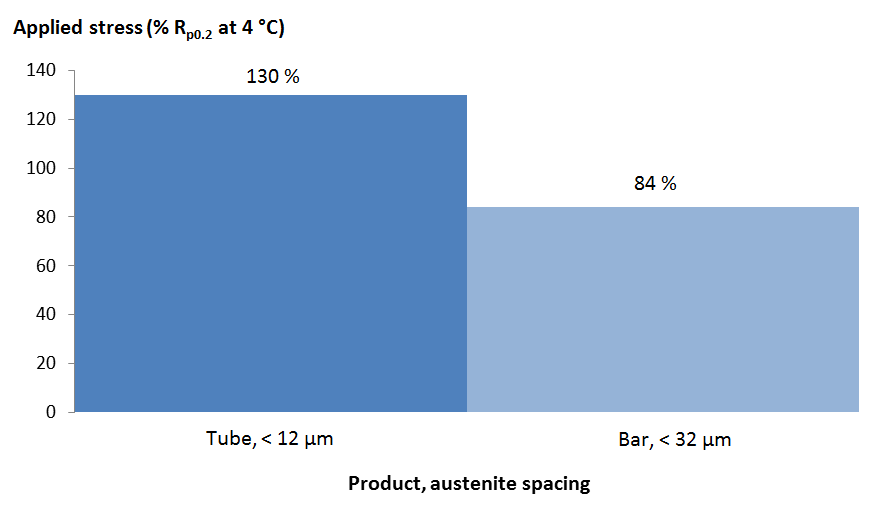

В супердуплексных нержавеющих сталях трещины имеют тенденцию распространяться в охрупченной ферритной фазе и останавливаться на границах фаз феррит-аустенит. Восприимчивость к HISC значительно увеличивается с увеличением расстояния между аустенитом. Поэтому крупнозернистые микроструктуры более восприимчивы. Программа испытаний, проведенная в Alleima Materials Technology, подтвердила, что склонность к HISC снижается, когда расстояние между аустенитом составляет менее 30 мкм, как рекомендовано DNV RP-F112. Холодносвайные и отожженные на твердый раствор трубы с расстоянием между аустенитом от 5 до 15 мкм показали очень хорошую устойчивость к HISC при приложенном напряжении до 130% от предела текучести без образования трещин.

Допустимое напряжение без возникновения HISC для изделий с различным интервалом аустенита показано на рисунке 16.

Рисунок 16. Допустимое напряжение в процентах от фактического предела текучести при 4°C без возникновения HISC схематически показано для трубных и стержневых изделий с различным интервалом аустенита. SAF™ 2507 (UNS S32750) был испытан на предварительно заряженных водородом образцах на растяжение с использованием постоянной нагрузки с мертвым грузом, с приложенным потенциалом -1050 мВ/SCE в электрохимической ячейке с 3% раствором NaCl при 4°C, 500 часов. [Документ NACE № 07498]

Межкристаллитная коррозия

SAF™ 2507 является представителем семейства современных дуплексных нержавеющих сталей, химический состав которых сбалансирован для быстрого преобразования аустенита в зоне высокотемпературного термического воздействия сварного шва. Это приводит к микроструктуре, которая обеспечивает материалу хорошую стойкость к межкристаллитной коррозии. SAF™ 2507 проходит испытания по ASTM A262 Practice E (тест Штрауса) без оговорок.

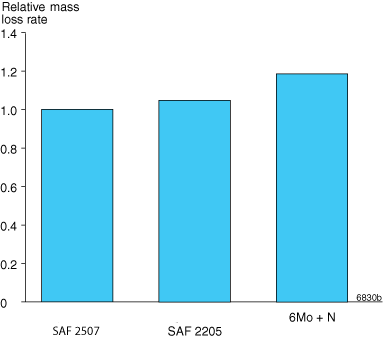

Эрозия, коррозия

Механические свойства в сочетании с коррозионной стойкостью придают SAF™ 2507 хорошую стойкость к эрозионной коррозии. Испытания в среде, содержащей песок, показали, что SAF™ 2507 имеет лучшую стойкость к эрозионной коррозии, чем соответствующие аустенитные нержавеющие стали. На рисунке 17 ниже показана относительная скорость потери массы дуплексной стали SAF™ 2507, SAF™ 2205 и аустенитной стали типа 6Mo+N после воздействия синтетической морской воды (ASTM D-1141), содержащей 0,025-0,25% кварцевого песка со скоростью 8,9-29,3 м/с (показано среднее значение всех испытаний).

Рисунок 17. Относительная скорость потери массы после испытания на стойкость к эрозионной коррозии.

Коррозионная усталость

Дуплексные нержавеющие стали, обладающие высокой прочностью на разрыв, обычно имеют высокий предел усталости и высокую стойкость как к усталости, так и к коррозионной усталости.

Высокая усталостная прочность SAF™ 2507 объясняется его хорошими механическими свойствами, а его высокая стойкость к коррозионной усталости доказана испытаниями на усталость в агрессивных средах.

ОБРАБОТКА

Hot Forming

2507 можно подвергать горячей формовке при температурах от 1875°F до 2250°F. Затем следует провести отжиг на твердый раствор при минимальной температуре 1925°F, а затем быстро закалить на воздухе или в воде.

Холодная формовка

Холодная обработка 2507 может быть выполнена с использованием большинства типичных процессов формовки нержавеющей стали. Поскольку сплав имеет более высокий предел текучести, чем аустенитные стали, но более низкую пластичность, производителям может потребоваться использовать более высокие силы формовки, большие радиусы изгиба и допуски на пружинение. Глубокая вытяжка, растяжение и другие подобные процессы более сложны для 2507, чем для аустенитных нержавеющих сталей. Отжиг на твердый раствор и закалка рекомендуются, когда процесс формовки требует более 10% холодной деформации.

Термическая обработка Термическая

обработка для 2507 состоит из отжига на твердый раствор и закалки после горячей или холодной формовки. Отжиг на твердый раствор следует проводить при минимальной температуре 1925°F. Отжиг должен немедленно сопровождаться быстрой закалкой на воздухе или в воде. Изделия, прошедшие термическую обработку, которые протравлены и промыты, обладают превосходной коррозионной стойкостью.

Сварка

2507 сваривается и может быть соединен с другими материалами с помощью SMAW, GTAW, PAW, FCW или SAW. При сварке 2507 рекомендуется использовать присадочный металл 2507/P100 для обеспечения надлежащей конструкции дуплексного сварного шва.

2507 не требует предварительного нагрева, за исключением предотвращения конденсации на холодном металле. Межпроходная температура сварки не должна превышать 300°F, иначе целостность шва будет нарушена. Для максимальной коррозионной стойкости следует применять защиту корня шва с использованием аргона или продувочного газа 90% N2/10% H2. Последний обеспечивает более высокую коррозионную стойкость.

Труба из нержавеющей стали марки 2507/S32750

Широкий выбор размеров и свободная резка

- Независимо от ваших потребностей, Daxun Alloys имеет идеальную трубу из нержавеющей стали для вас. Мы предлагаем длины 3 м и 6 м, диаметрами от 3 мм до 2000 мм (сорт 2507) и от ¾” до 20″ (сорт S32750).

- Если вам нужна определенная длина, мы предлагаем бесплатную неограниченную услугу резки с каждой покупкой. Используя современные ленточные пилы, наша служба точной резки может отрезать трубу до нужной вам длины. Просто дайте нам знать при заказе. Это еще одна причина, по которой мы являемся ведущим поставщиком труб из нержавеющей стали для наших внутренних и международных клиентов.

Свяжитесь с поставщиками труб из нержавеющей стали.

- Вы можете легко заказать трубы из нержавеющей стали онлайн любого размера и в любом количестве.

- В качестве альтернативы, наша дружелюбная команда по продажам будет рада принять ваш заказ. Просто позвоните +86 13382898899 или напишите по электронной почте Daxunhejin@gmail, и мы свяжемся с вами как можно скорее.

Вы многому научитесь, работая над большим количеством проектов по строительству скважин и шлангокабелей совместно с Daxun Alloys.

Вы узнаете, как производить и поставлять прямые и гибкие трубы из нержавеющей стали и никеля, которые являются как комплексными, так и экономически эффективными. Вы узнаете, как гарантировать качество, используя несколько методов неразрушающего контроля. Вы узнаете, как разрабатывать технологические планы специально для клиентов, работающих в области скважин и шлангокабелей.

Когда вы выбираете Daxun Alloys в качестве поставщика труб, вы знаете, что мы действительно понимаем нефтегазовую отрасль. Свяжитесь с Daxun Alloys сегодня.

Работая в сфере производства электроэнергии, только DEXON Alloys объединяет технические знания и опыт для производства лучших труб, доступных на рынке сегодня. Выбирайте лучшее, и вы получите лучшее. Делайте так, как делают бесчисленные другие компании — доверяйте DEXON Alloys. Требовательные отрасли промышленности требуют DEXON Alloys.

Только DEXON Alloys, обслуживающая химическую и нефтехимическую промышленность, объединяет технические знания и опыт для производства лучших труб, доступных на рынке сегодня. Выбирайте лучшее, и вы получите лучшее. Делайте так, как делают бесчисленные другие компании — доверяйте DEXON Alloys. Требовательные отрасли промышленности требуют DEXON Alloys.

Иногда хорошие ингредиенты смешиваются с плохими. Когда ваш продукт течет через трубу DAIXUN Alloy, плохих вещей больше нет. Это потому, что внутренняя структура, изготовленная DAIXUN, ограничивает крошечные щели, где могут скрываться патогены. Улучшите качество, подключившись к материалам DAIXUN Alloy.

Обслуживание фармацевтической и биофармацевтической промышленности является вызовом для Daxun Alloys. От выбора сырья до доставки мы формулируем наши услуги высокой и сверхвысокой чистоты, чтобы соответствовать и превосходить отраслевые стандарты. Когда только трубки и трубы высочайшего качества будут соответствовать потребностям, все больше фармацевтических и биофармацевтических компаний доверяют Daxun Alloys.

Обслуживание специализированной автомобильной промышленности путем установления стандарта для специализированных выхлопных систем. Трубы и патрубки Daxun Alloy специально разработаны для сопротивления разрыву, коррозии и термическому окислению. Для обеспечения стабильной производительности и непревзойденного обслуживания обращайтесь в Daxun Alloy.

Мы можем предоставить образцы листов нержавеющей стали для проверки качества. Образец бесплатный, вы платите только за доставку.

Мы экспортируем продукцию в более чем 42 страны, такие как Канада, Чили, Кувейт, Германия, Южная Корея, Саудовская Аравия, Сингапур и т. д.

Минимальный объем заказа составляет 1 тонну листа нержавеющей стали.

Пробные заказы могут быть доставлены в течение недели. Для обычных заказов это занимает около двух недель.