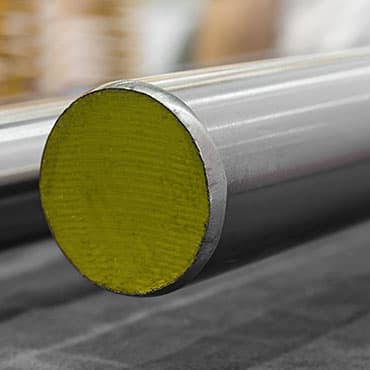

Дуплексная 2205 пруток нержавеющий

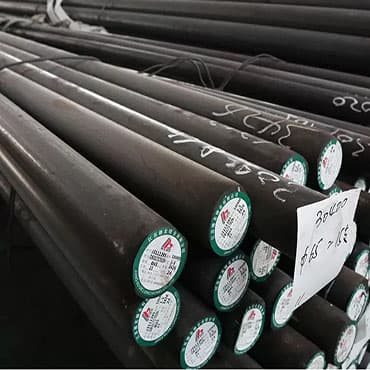

Являясь ведущим поставщиком и экспортером нержавеющей стали в Китае, компания Daxun поставляет прутки (круглые прутки) из нержавеющей стали по всему миру.

- Марка: AISI 2205-S32205-S31803

- Производство: горячекатаный, холоднотянутый, кованный

- Стандарты: GOST,ASTM, ASME, GB, DIN, JIS, ISO.

- Высокая стойкость к коррозионному растрескиванию под напряжением, усталости и эрозии

- Более высокая теплопроводность и меньшее тепловое расширение, чем у аустенитных сталей

- Отличная и равномерная стойкость к точечной и щелевой коррозии

- Хорошая стойкость к сульфидному коррозионному растрескиванию под напряжением

Мировой лидер в сфере услуг по изготовлению прутков из нержавеющей стали и круглого проката

Технические характеристики продукта

- ASTM A479 UNS S32205 Бар

- Круглый пруток дуплексный ASTM A276 F60

- Круглый пруток ASTM A479 UNS S32205

- UNS S32205 Дуплексный круглый пруток

- Производитель прутков из дуплексной стали S32205 из Китая

Обзор

Стержни из дуплексной стали S32205 используются во многих отраслях промышленности благодаря своим великолепным свойствам и универсальности. S32205 — это дуплексная нержавеющая сталь, которая имеет как аустенитные, так и ферритные характеристики. Это обеспечивает ей высокую прочность, отличную коррозионную стойкость и экономическую эффективность.

Состав и свойства

Дуплексная сталь S32205 содержит около 22% хрома, 5-6% никеля, 3% молибдена и большое количество азота. Такое сочетание делает ее очень устойчивой к коррозии и очень прочной. В ее структуре есть как аустенит, так и феррит, что делает ее прочнее и лучше обычных аустенитных или ферритных нержавеющих сталей.

Коррозионная стойкость

Одной из основных особенностей стержней S32205 является их устойчивость к различным типам коррозии. Они обладают высокой устойчивостью к точечной и щелевой коррозии в хлоридных средах, что делает их идеальными для использования в коррозионных зонах, таких как химическая обработка, морские условия и морская нефтегазовая промышленность.

Наша сеть сервисных центров располагает складом прутков из нержавеющей стали для быстрой и готовой поставки прутков обычных размеров и сплавов. Мы также производим прутки из нержавеющей стали по индивидуальным размерам и можем составить графики поставок для быстрого выполнения заказов в установленные сроки, если объемы окажутся ниже минимально допустимых на заводе. Компания Daxun Alloys располагает складом круглых прутков из нержавеющей стали диаметром от 1/16″ до 26″. Круглые прутки доступны почти из всех марок нержавеющей стали, включая 302, 303, 304/L, 309/S, 310/S, 316/L, 317/L, 321, 321/H, 347, 347H, 410, 416, 420, 440C, 17-4PH, Duplex 2205 и Alloy 20. Закаленные круглые прутки из нержавеющей стали предлагаются в 17-4PH, закалке H900 (по запросу), H1025, H1150, Double H1150 и H1150M. Другие закаленные закалки могут быть изготовлены по запросу. Мы поставляем следующие виды нержавеющей стали 400-й серии: 410, 430 и 416. Мы также поставляем прецизионные и подшипниковые прутки из нержавеющей стали 303, 304 и 316/L. Большая часть нашего инвентаря состоит из наших уникальных сортов обработанных прутков: прутков из нержавеющей стали, которые плавятся в соответствии со стандартами для повышения обрабатываемости и снижения общей стоимости компонента. Наше оборудование для обработки прутков из нержавеющей стали позволяет Daxun Alloys производить продукцию в точном соответствии с техническими требованиями наших клиентов.

- Параметр

- Ингредиенты

- Механические свойства

- ФИЗИЧЕСКИЕ СВОЙСТВА

- Все эквивалентно

- Типы

| Параметры продукта: стержень из нержавеющей стали | |

| Технические характеристики | ГОСТ 5949-75,ГОСТ 2590-2006,ГОСТ 5582-75 ASTM A276, ASME SA276 / ASTM A479 ASME SA479 |

| Размеры | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Круглые прутки SS 2205/S32205 | Наружный диаметр в диапазоне от 4 мм до 500 мм |

| SS 2205/S32205 Яркие полосы | Внешний диаметр в диапазоне от 4 мм до 100 мм |

| Шестигранные стержни SS 2205/S32205 | 18 мм – 57 мм (от 11/16″ до 2-3/4″) |

| Заканчивать | Черный, полированный, грубая обработка, отделка № 4, матовая отделка, отделка BA |

| Длина | От 1 до 6 метров, индивидуальная длина отрезка |

| Форма | Круг, квадрат, шестигранник (A/F), прямоугольник, заготовка, слиток, поковка и т. д. |

| Оценка | С | Мн | Си | П | С | Кр | Мо | Ни | Н |

| 2205 | 0,03 | 2 | 1 | 0,03 | 0,02 | мин: 21.0 | мин: 2.5 | мин: 4.5 | мин: 0,08 |

| (S31803) | макс | макс | макс | макс | макс | макс: 23.0 | макс: 3,5 | макс: 6.5 | макс: 0,20 |

| 2205 | 0,03 | 2 | 1 | 0,03 | 0,02 | мин: 22.0 | мин: 3.0 | мин: 4.5 | мин: 0,14 |

| (С32205) | макс | макс | макс | макс | макс | макс: 23.0 | макс: 3,5 | макс: 6.5 | макс: 0,20 |

| Оценка | Предел прочности | Предел текучести | Удлинение | Твёрдость | |

| (МПа) мин | 0,2% Доказательство | (% в 50 мм) мин. | |||

| (МПа) мин | Роквелл C (HR C) | Твёрдость по Бринеллю (HB) | |||

| УНС S31803 / 2205 | 621 | 448 | 25 | 31 макс. | 293 макс. |

| УНС S32205 / 2205 | 621 | 448 | 25 | 31 макс. | 293 макс. |

| Класс 2205 | Плотность | Эластичный | Средний коэффициент термич. | Термальный | Специфический | Электрические | |||

| (кг/м3) | Модуль(ГПа) | Расширение (мкм/м/°C) | Проводимость (Вт/мК) | Нагревать | Удельное сопротивление | ||||

| 0-100°С | 0-315°С | 0-538°С | при 100°С | при 500°С | 0-100°C (Дж/кг.К) | (нОм.м) | |||

| UNS S32205 / UNS S31803 | 782 | 190 | 13.7 | 14.2 | – | 19 | – | 418 | 850 |

| Оценка | КИТАЙ | УНС | Старый британский | Евронорма | Шведские СС | Японский JIS | ||

| Нет | БС | En | Нет | Имя | ||||

| 2205 | 022Cr23Ni5Mo3N | С31803 / С32205 | 318С13 | – | 1.4462 | X2CrNiMoN22-5-3 | 2377 | SUS329J3L |

| Нержавеющая сталь 2205/S32205/S31803 Светлая полоса | SS 2205/S32205/S31803 Яркая полоса |

| 2205/S32205/S31803 SS Светлая полоса | |

| Нержавеющая сталь 2205/S32205/S31803 Светлая полоса | |

| UNS S2205/S32205/S3180300 SS Светлая полоса | |

| ВЕРКСТОФФ Н.Р. 1.4462 Яркая полоса | |

| ASTM A276 2205/S32205/S31803 Нержавеющая сталь, блестящая планка | |

| Шестигранный стержень из нержавеющей стали 2205/S32205/S31803 | Шестигранный стержень SS 2205/S32205/S31803 |

| 2205/S32205/S31803 Шестигранный стержень из нержавеющей стали | |

| 2205/S32205/S31803 Шестигранный стержень из нержавеющей стали | |

| Шестигранный стержень из нержавеющей стали UNS S2205/S32205/S3180300 | |

| Шестигранный стержень из нержавеющей стали ASTM A276 2205/S32205/S31803 | |

| Квадратный пруток из нержавеющей стали 2205/S32205/S31803 | SS 2205/S32205/S31803 Квадратный пруток |

| 2205/S32205/S31803 Квадратные прутки из нержавеющей стали | |

| 2205/S32205/S31803 Квадратный пруток из нержавеющей стали | |

| UNS S2205/S32205/S3180300 квадратный стержень из нержавеющей стали | |

| ВЕРКСТОФФ Н.Р. 1,4462 Квадратный стержень | |

| Квадратные прутки из нержавеющей стали ASTM A479 2205/S32205/S31803 | |

| Прямоугольный пруток из нержавеющей стали 2205/S32205/S31803 | SS 2205/S32205/S31803 Прямоугольный брус |

| 2205/S32205/S31803 Прямоугольные стержни из нержавеющей стали | |

| 2205/S32205/S31803 Прямоугольный пруток из нержавеющей стали | |

| Прямоугольные стержни из нержавеющей стали UNS S2205/S32205/S3180300 | |

| ВЕРКСТОФФ Н.Р. 1.4462 Прямоугольный стержень | |

| Прямоугольный пруток из нержавеющей стали ASTM A276 2205/S32205/S31803 | |

| Плоские прутки из нержавеющей стали 2205/S32205/S31803 | SS 2205/S32205/S31803 Плоский пруток |

| 2205/S32205/S31803 Плоские прутки из нержавеющей стали | |

| 2205/S32205/S31803 Плоские прутки из нержавеющей стали | |

| Плоские прутки из нержавеющей стали UNS S2205/S32205/S3180300 | |

| ВЕРКСТОФФ Н.Р. 1.4462 Плоские стержни | |

| ASTM A276 2205/S32205/S31803 Плоские прутки из нержавеющей стали | |

| Полированный брусок из нержавеющей стали 2205/S32205/S31803 | SS 2205/S32205/S31803 Полированный брусок |

| 2205/S32205/S31803 Полированные прутки из нержавеющей стали | |

| 2205/S32205/S31803 Полированный брус из нержавеющей стали | |

| Полированные прутки из нержавеющей стали UNS S2205/S32205/S3180300 | |

| ВЕРКСТОФФ Н.Р. 1.4462 Полированный стержень | |

| Полированный пруток из нержавеющей стали ASTM A476 2205/S32205/S31803 | |

| Резьбовой стержень из нержавеющей стали 2205/S32205/S31803 | Резьбовой стержень SS 2205/S32205/S31803 |

| 2205/S32205/S31803 Резьбовые стержни из нержавеющей стали | |

| 2205/S32205/S31803 Резьбовой стержень из нержавеющей стали | |

| Резьбовой стержень из нержавеющей стали UNS S2205/S32205/S3180300 | |

| ВЕРКСТОФФ Н.Р. 1.4462 Резьбовой стержень | |

| Резьбовой стержень из нержавеющей стали ASTM A276 2205/S32205/S31803 |

Выбирайте Daxun и сделайте своих клиентов довольными.

Быстрый ответ

Мы обеспечиваем своевременную и быструю доставку прутковой продукции из нержавеющей стали 2205 для клиентов с срочными потребностями. За скоростью стоит системная поддержка от информационного потока до логистики и движения капитала. Например, с точки зрения информационного потока данные о заказах Daxun передаются в логистическую систему в режиме реального времени, и данные бесшовно связаны; с точки зрения логистики центр обработки находится недалеко от автомагистралей, рек и морей, с разумным планированием, быстрым реагированием, складскими и транспортными связями и эффективной загрузкой, чтобы гарантировать, что задача будет выполнена вовремя.

Преимущества Даксуна

- Разновидности: Мы предлагаем широкий ассортимент размеров и марок, включая серии 300, 400, 600 и другие.

- Гибкость: независимо от того, нужны ли вам горячекатаные или холоднотянутые прутки, длина наших прутков из нержавеющей стали подбирается в соответствии с требованиями вашего конкретного проекта.

- Стандарты качества: Наши трубы из нержавеющей стали соответствуют строгим стандартам ASTM, ISO9001, GB, NSF/ANSI, что гарантирует надежность и производительность.

- Индивидуальные заказы: Ищете специальные размеры прутков из нержавеющей стали? Мы предлагаем различные варианты изготовления прутков из нержавеющей стали по конкурентоспособным ценам и с удобным онлайн-заказом.

Упаковка стержня из нержавеющей стали 2205

Мы уделяем внимание каждому процессу, чтобы гарантировать качество. Упаковка, которую мы обычно применяем, заключается в упаковке круглых прутков из нержавеющей стали 2205 в экологически чистые пластиковые пакеты, а затем в деревянные ящики или деревянные поддоны, не прошедшие фумигацию. Также можно обсудить индивидуальную упаковку, например OEM. Мы предоставляем практически все, чтобы удовлетворить ваши требования к упаковке круглых прутков. Мы придаем большое значение упаковке. Круглые прутки упаковываются в деревянные гофрированные коробки, обертываются пластиковой упаковкой и пузырчатой пленкой снаружи.

Качество, доставка, проверка

- Daxun проводит несколько испытаний на обеспечение качества, включая испытания на сплющивание, испытания на стойкость к питтингу, механические испытания, испытания на твердость, идентификацию материалов и испытания на расширение. Эти испытания гарантируют, что материалы соответствуют всем требуемым стандартам для их предполагаемого применения.

- Мы поддерживаем проведение инспекций клиентов сторонними агентствами, предоставляем бесплатные образцы для тестирования, а также предлагаем как выездные, так и видеозапись инспекций на заводе.

Техническая поддержка

Если вам нужна дополнительная техническая помощь, наш местный металлург и знающий персонал будут рады помочь. Кроме того, Daxun может похвастаться сертифицированной испытательной лабораторией — первой в отрасли многометаллического и пластикового инвентаря. Это, по нашему мнению, демонстрирует нашу непоколебимую преданность качеству и нашу философию как поставщика полного спектра услуг.

Информация для заказа стержня из нержавеющей стали 2205

При размещении заказа на круглые прутки из нержавеющей стали 2205, пожалуйста, укажите следующую информацию:

- Количество

- класс ПСЛ

- Тип или категория

- Ссылка API5L

- Диаметр

- Отделка поверхности

- Длина

- Любые другие особые требования, касающиеся химического состава, механических свойств, термической обработки, дополнительных испытаний, производственного процесса, отделки поверхности или конечной обработки.

- Условия оплаты, включая требования к депозиту и доступные варианты, такие как T/T и L/C.

Все прутки подвергнуты светлому отжигу.

Характеристики стержня из нержавеющей стали 2205-S32205-S31803

Daxun Alloy Позвольте вашему бренду быстро улучшиться

- Галерея

- Состояние доставки

- Возрастная закалка

| Выбор штата доставки | Состояние поверхности |

| Кованый | Черный |

| Полированный | |

| Горячекатаный | Черный |

| Полированный | |

| Яркий | |

| Маринованный | |

| Холоднотянутый | Полированный |

| Яркий | |

| Примечание: | |

| 1. Если вам требуется другой штат доставки, чем указанный выше, пожалуйста, уточните у нас. | |

| 2. В случае возникновения каких-либо вопросов или заказов, пожалуйста, сообщите нам о любых дополнительных требованиях, не указанных здесь. | |

| Материал в состоянии, подвергнутом отжигу на твердый раствор, может быть подвергнут старению следующим образом: *Обозначает двойное старение | ||||||||||||

| Состояние | Н900 (Н480) | Н925 (Н495) | Н1025 (Н550) | Н1075 (Н580) | Н1100 (Н595) | Н1150 (Н620) | Н1150М (Н620М)* | Плюс | H1150D (H620D)* | Плюс | ||

| Нагреть до | ±15oF | 900oF | 925 градус по Фаренгейту | 1025oF | 1075oF | 1100oF | 1150oF | 1400oF | 1150oF | 1150oF | 1150oF | |

| ±9oC | 480оС | 495oC | 550oC | 580oC | 595oC | 620oC | 760oC | 620oC | 620oC | 620oC | ||

| Удерживать в течение нескольких часов | 1 | 4 | 4 | 4 | 4 | 4 | 2 | 4 | 4 | 4 | ||

| Охлаждение до температуры ниже | Воздух | Воздух | Воздух | Воздух | Воздух | Воздух | Воздух | Воздух | Воздух | Воздух | ||

| 90oF (32oC) | ||||||||||||

Информация доступна для ознакомления и скачивания

Производство прутков из нержавеющей стали

Daxun — надежный производитель прутков и стержней из нержавеющей стали.

Как профессиональный производитель, Daxun гарантирует, что вся производимая нами продукция отличается высоким качеством. Поэтому мы гарантируем, что все нержавеющие прутки сертифицированы по стандартам ISO9001, SGS, CE, OQC

Последние горячие проекты и продукты

Сопутствующие товары (12)

Круглый пруток из дуплексной нержавеющей стали 2205 — это прочный тип стали, содержащий 22% хрома, 3% молибдена и 5-6% никеля. Он обладает как ферритными, так и аустенитными свойствами, что делает его прочнее обычных нержавеющих сталей. У 2205 вдвое больший предел текучести, чем у стандартных нержавеющих сталей, и он очень устойчив к коррозии в жестких условиях. Он также обладает хорошей усталостной прочностью и противостоит растрескиванию под напряжением, точечной коррозии, щелевой коррозии и эрозии, что делает его полезным для сложных применений.

- Химическая переработка, транспортировка и хранение – сосуды под давлением, резервуары, трубопроводы и теплообменники

- Оборудование для разведки и переработки нефти и газа – трубопроводы, трубки и теплообменники

- Морская и другая среда с высоким содержанием хлоридов

- Системы очистки сточных вод

- Целлюлозно-бумажная промышленность – варочные котлы, отбеливающее оборудование и системы обработки запасов

- Грузовые танки для кораблей и грузовиков

- Оборудование для пищевой промышленности

- Биотопливные заводы

- ASTM/ASME: A240 UNS S32205/S31803

- ЕВРОНОРМА: 1.4462 X2CrNiMoN 22.5.3

- AFNOR: Z3 CrNi 22.05 AZ

- DIN: W.Nr 1.4462

Мы можем предоставить вам образцы прутков из нержавеющей стали 2205 для проверки качества. Образец бесплатный, вы платите только за доставку.

КОРРОЗИОННАЯ УСТОЙЧИВОСТЬ

- Высокое содержание хрома, молибдена и азота делает нержавеющую сталь Duplex 2205 более устойчивой к коррозии, чем марки 316 и 316L.

- Обеспечивает защиту от точечной и щелевой коррозии даже в жестких или кислых средах.

- Устойчив к хлоридному коррозионному растрескиванию под напряжением.

- Выдерживает температуру до 302°F (150°C).

- Феррит в его структуре позволяет ему хорошо работать в едких средах.

- Подходит для сложных условий.

ТЕПЛОУСТОЙЧИВОСТЬ

- Duplex 2205 обладает хорошей стойкостью к окислению при высоких температурах, как и другие дуплексные нержавеющие стали.

- Становится хрупким при воздействии температур свыше 572°F (300°C) даже в течение короткого времени.

- Не рекомендуется использовать при температуре выше 572°F (300°C).

Характеристики сварки

- Duplex 2205 обладает хорошей свариваемостью.

- Не следует выполнять сварку без присадочного металла, так как это может привести к чрезмерному содержанию феррита.

Термическая обработка

- Диапазон температур отжига составляет от 1020 до 1100 °C (от 1868 до 2012 °F).

- Не поддается упрочнению путем термической обработки, но упрочняется при деформации.

- Особое внимание следует уделять работе с более высоким коэффициентом теплового расширения, чтобы избежать коробления и искажения.

ОБРАБОТКА – ГОРЯЧАЯ ФОРМОВКА

Большинство производителей рекомендуют поддерживать температуру горячего формования для Duplex 2205 в диапазоне от 2010 до 2100°F (от 1100 до 1150°C). Если форма некомпактная, края могут остывать быстрее, чем центр, что может привести к растрескиванию.

ОБРАБОТКА – ХОЛОДНАЯ ФОРМОВКА

Duplex 2205 может быть сформирован разными способами, но его высокая прочность делает его более сложным. Даже с мощным оборудованием вам нужно учитывать дополнительную отдачу из-за его прочности.

ОБРАБАТЫВАЕМОСТЬ

Нержавеющая сталь Duplex 2205 немного сложнее в обработке, чем нержавеющая сталь серии 300. Она требует большего усилия резания, что ускоряет износ инструментов. Вот несколько советов по обработке:

- Используйте прочный, жесткий станок с надежными креплениями инструмента и заготовки.

- Используйте короткие удлинители инструментов, чтобы снизить вибрацию.

- Избегайте большого радиуса заточки инструмента, чтобы карбид оставался острым, но прочным.

- Планируйте обработку таким образом, чтобы глубина реза оставалась ниже закаленного слоя от предыдущих проходов.

Тестирование

- Вот испытания, которые мы проводим для нержавеющей стали Duplex 2205:

- Положительный тест на идентификацию материала

- Испытание на межкристаллитную коррозию

- Испытание на стойкость к точечной коррозии

- Механическое испытание

- Химический тест

- Макро/микро тест

- Испытание на сплющивание/расширение

Документы предоставлены

- Карта лечения сердца, план обеспечения качества, коммерческий счет-фактура, сертификат происхождения, отчет об испытаниях сырья, отчет о прослеживаемости материалов и т. д. — вот несколько важных документов, предоставляемых покупателям. Кроме того, предоставляются другие документы, такие как MTC согласно EN 10204/3.1B, TC, например, отчет об испытаниях рентгенографии и отчет об испытаниях третьей стороны.

Круглые прутки из нержавеющей стали марки 2205-s32205-S31803

Мы предоставляем важные документы, такие как:

- Таблица термической обработки

- План обеспечения качества

- Счет-фактура

- Сертификат происхождения

- Отчет об испытаниях сырья

- Отчет о прослеживаемости материалов

Предоставленные документы

Мы предоставляем важные документы, такие как:

- Таблица термической обработки

- План обеспечения качества

- Счет-фактура

- Сертификат происхождения

- Отчет об испытаниях сырья

- Отчет о прослеживаемости материалов

Мы также предоставляем другие документы, такие как сертификат испытаний материалов (MTC) в соответствии с EN 10204/3.1B, отчет о радиографических испытаниях и отчет об испытаниях третьей стороной.

Наши круглые прутки из нержавеющей стали поставляются во многих размерах. Вы можете выбрать нужную вам марку, с длиной от 500 мм до 6 метров и диаметром от 3 мм до 500 мм. Мы предлагаем как метрические, так и имперские размеры. Если вам нужны нестандартные размеры, мы предоставляем бесплатную резку с использованием современных ленточных пил, чтобы убедиться, что все сделано правильно.

Минимальный заказ составляет 1 тонну прутка из нержавеющей стали марки 2205.